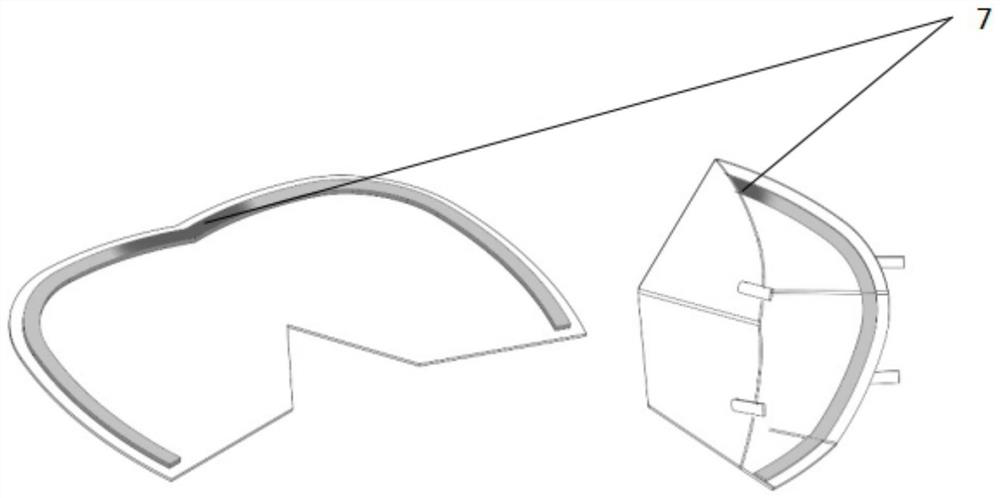

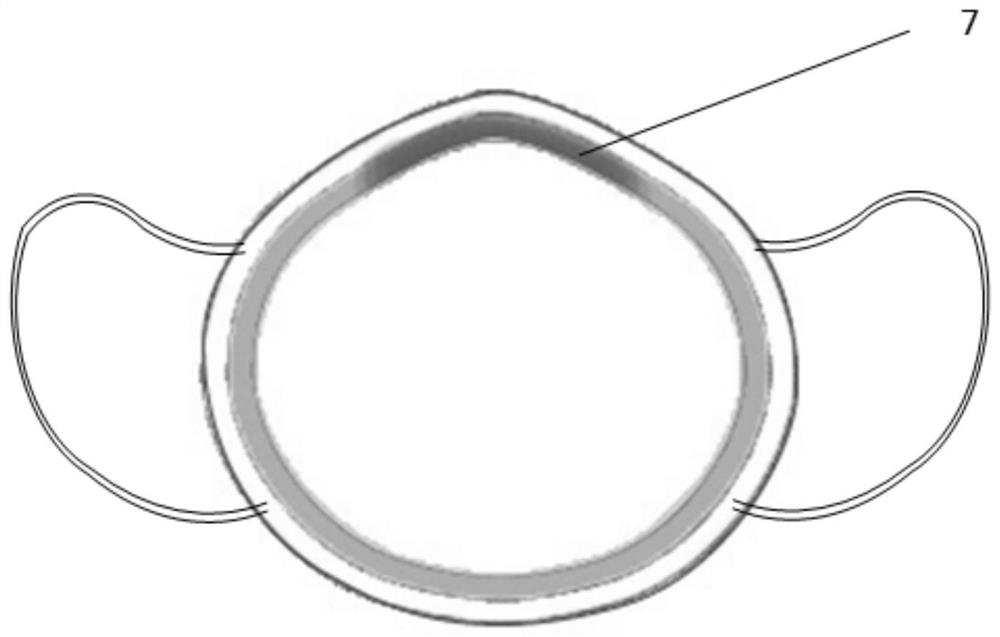

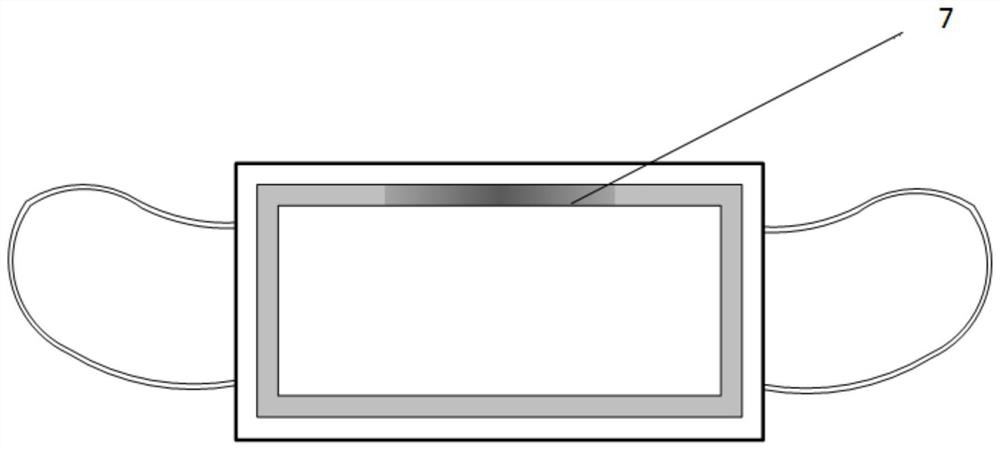

Preparation method of a flexible hydrogel and its application in high-performance medical protective equipment

A hydrogel, high-performance technology, applied in applications, protective clothing, clothing, etc., can solve the problems of mask-skin elastic modulus mismatch, uneven spatial pressure distribution, facial skin friction damage, etc., to achieve soft texture, The effect of increasing the contact area and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of Flexible Hydrogel

[0036] Include the following steps:

[0037](1) Using N-MBEDA and diisocyanate monomer, Sn(Oct) 2 As a catalyst, a condensation polymerization method is used to prepare a water-soluble polyurethane matrix PU-1, and then the reaction between the tertiary amine of PU-1 and ethyl bromide is used to prepare a polyurethane polymer PU-1(+) with constant cationic charge, specifically: :

[0038] According to the following chemical reaction formula, under the protection of dry nitrogen, the vacuum dehydrated N-MBEDA and diisocyanate monomers were poured into a 250 mL volume of 250 mL with reflux condensation at a molar ratio of 1:1 In a three-necked flask with a tube and a thermometer, take 2g Sn(Oct) 2 As a catalyst, N-MBEDA was used as a chain extender, mechanically stirred at 80 °C for 2 hours, and then heated to 85 °C for 2 hours to prepare a water-soluble polyurethane matrix (PU-1); then 0.1 mol of ethyl bromide was added. ,...

Embodiment 2

[0047] Example 2 Preparation of flexible hydrogels

[0048] Include the following steps:

[0049] Steps (1) and (2) are with embodiment 1;

[0050] (3) Using DMF (dimethylformamide) as a solvent, prepare PU-1(+) aqueous solution (concentration of 0.01mol) and PU-2(-) aqueous solution (concentration of 0.01mol), respectively, mix PU-1 ( The +)) aqueous solution and the PU-2(-)) aqueous solution were stirred at a volume ratio of 1:1 using a mechanical stirring bar for 30 min, and then the system temperature was kept at 30 °C for 6 h to obtain a liquid polyurethane hydrogel. Introduce the liquid polyurethane hydrogel into the mold, slowly add water along the inner wall of the mold, soak for a period of time, so that most of the solvent in the hydrogel is soaked out, and then vacuum dry to obtain a formed solid polyurethane hydrogel, that is, a flexible hydrogel. glue.

Embodiment 3

[0051] Example 3 Preparation of Flexible Hydrogel

[0052] Include the following steps:

[0053] Steps (1) and (2) are with embodiment 1;

[0054] (3) Using DMF (dimethylformamide) as a solvent, PU-1(+) aqueous solution (concentration of 0.1 mol) and PU-2(-) aqueous solution (concentration of 0.1 mol) were prepared respectively, and PU-1 ( The +)) aqueous solution and the PU-2(-)) aqueous solution were stirred at a volume ratio of 1:1 using a mechanical stirring bar for 30 min, and then the system temperature was kept at 30 °C for 6 h to obtain a liquid polyurethane hydrogel. Introduce the liquid polyurethane hydrogel into the mold, slowly add water along the inner wall of the mold, soak for a period of time, so that most of the solvent in the hydrogel is soaked out, and then vacuum dry to obtain a formed solid polyurethane hydrogel, that is, a flexible hydrogel. glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com