Small pipe outer wall electroplating device

An electroplating device and a technology for the outer wall of the tube, applied in the electrolysis process, electrolysis components, etc., can solve the problems of bottom offset, easy to fall off, uneven plated parts, etc., and achieve the effect of less solution volume, good electric field distribution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

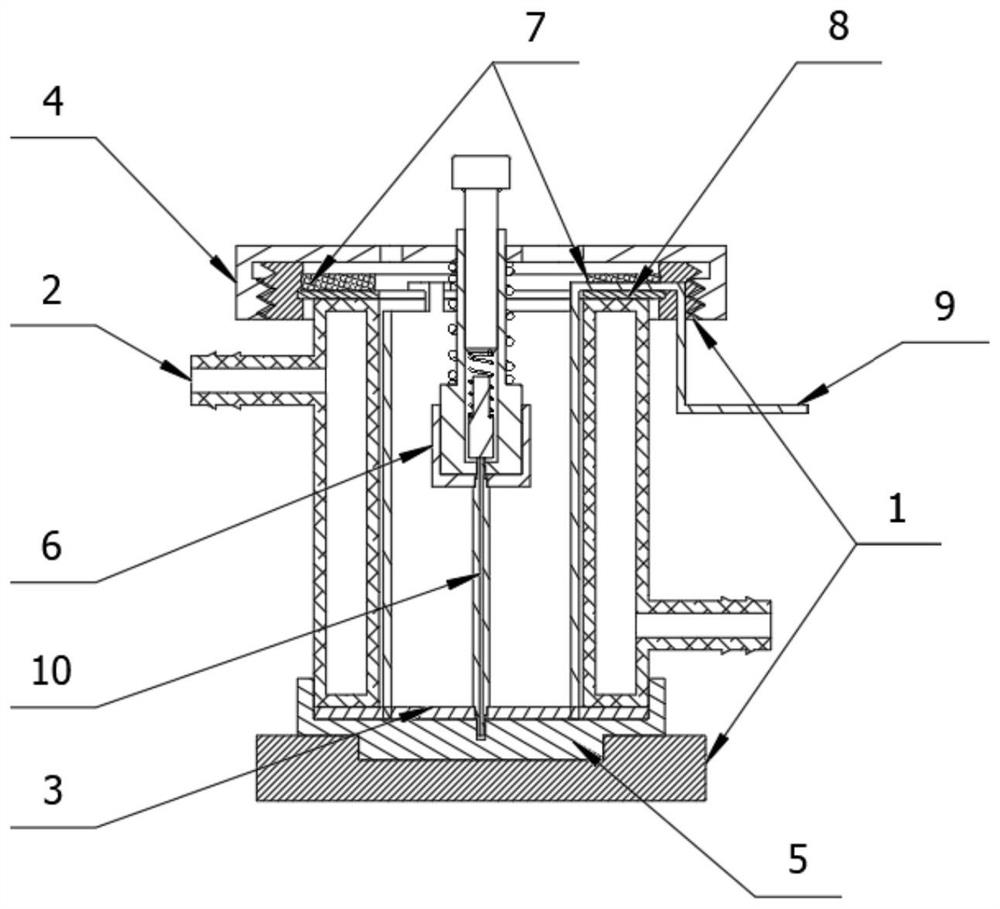

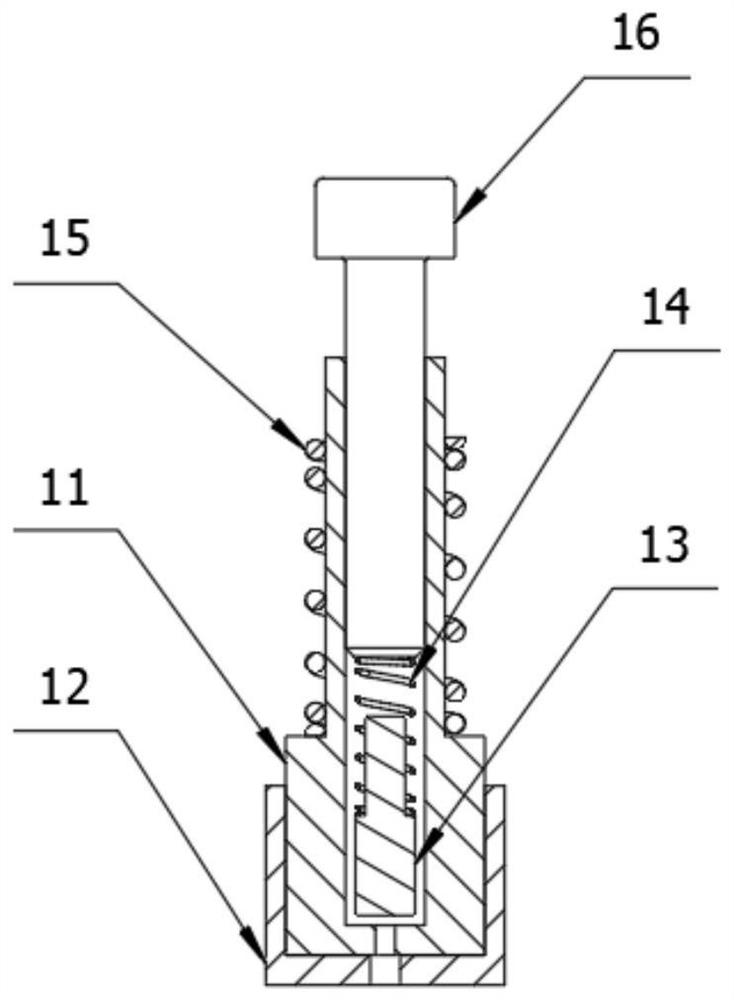

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] In order to solve the problems of large amount of electroplating solution, uneven distribution of electric field, and difficulty in local masking in the small tubes of traditional components, the present invention designs a device for electroplating actinide nuclides on the outer walls of small tubes. The device uses a small amount of plating solution, has uniform electric field distribution and does not need to use masking means such as tape wrapping, and is especially suitable for operation in a glove box of precious actinide raw materials.

[0022] against Figure 1 A typical plating piece schematic diagram (small tube is made up of electroplating area and non-plating area), and the specific implementation method is as follows;

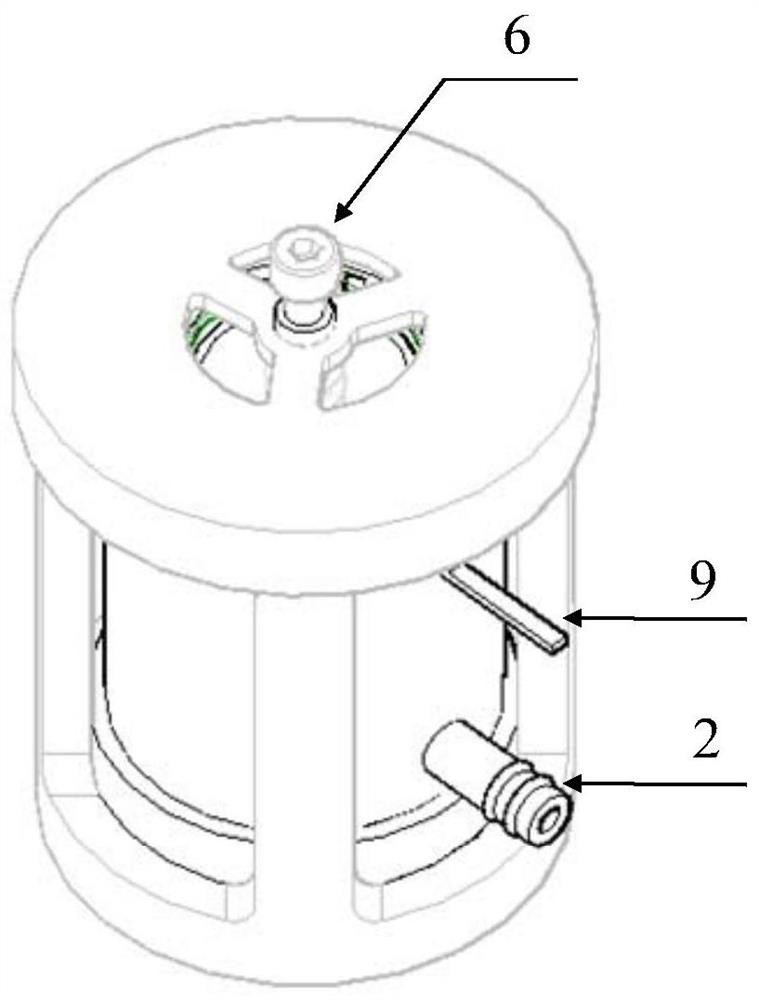

[0023] The electroplating device for the outer wall of the small tube comprises an electroplating tank s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com