Steel flower tube pile enclosure structure suitable for upper-soft lower-hard stratum and construction method

A technology of enclosure structure and steel flower tube, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., and can solve the problems of difficulty in driving steel sheet piles or SMW piles in hard rock formations and high project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

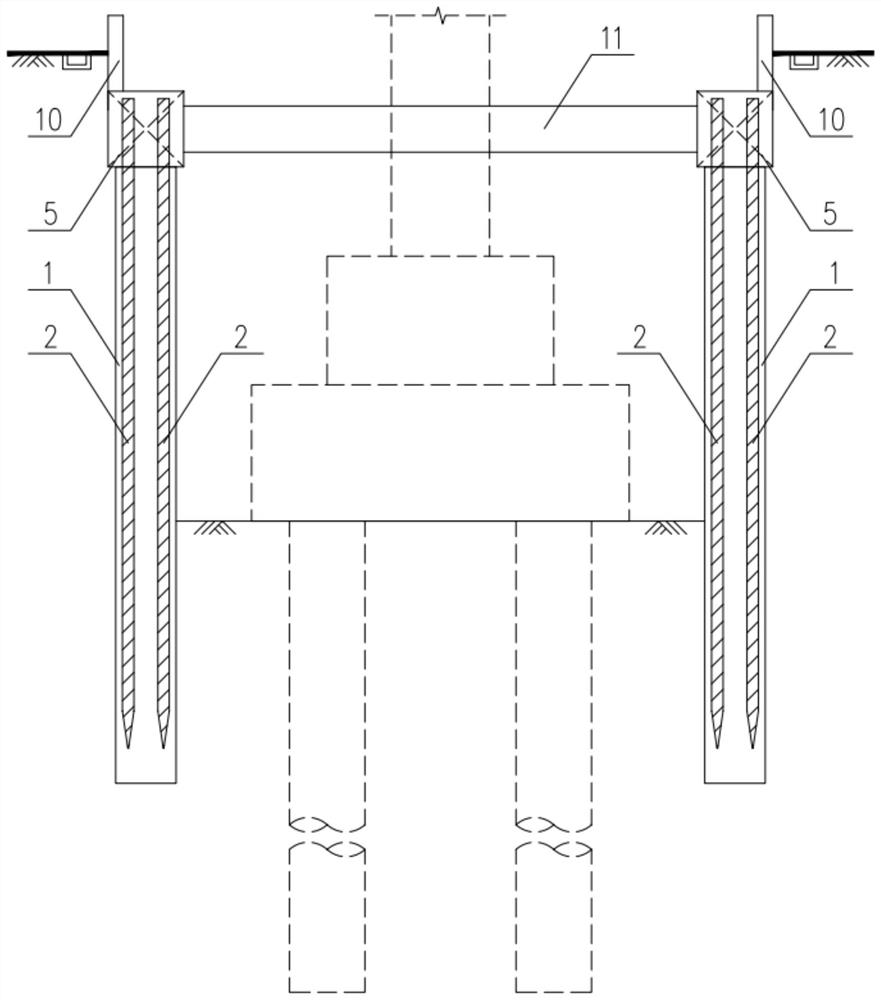

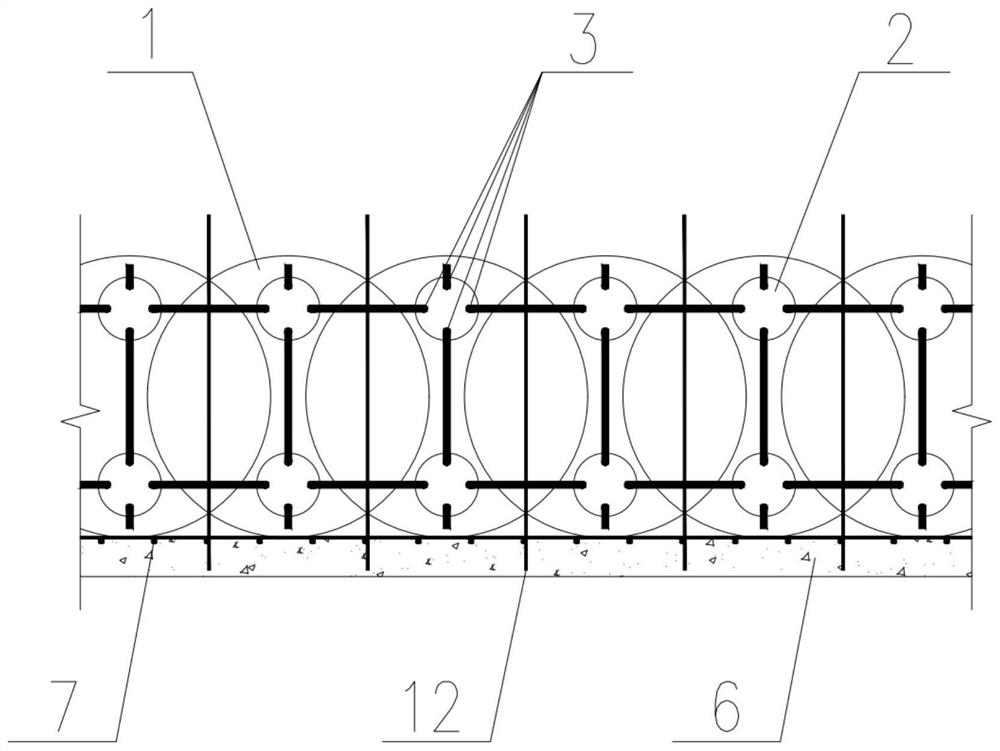

[0041] Such as figure 1 As shown, the enclosure structure includes high-pressure jet grouting piles, steel flower tubes and inserted steel cages, cement mortar in steel flower tubes, crown beams, shotcrete, steel mesh, retaining walls, etc., and each high-pressure jet grouting pile contains 2 Steel flower tube; high-pressure rotary grouting pile pile diameter 800mm, sprayed concrete between piles, steel flower tube diameter 219mm, steel flower tube wall thickness 12mm, crown beam width 1000mm, height 1000mm.

[0042]Before the rotary grouting pile is hardened, determine the center line of the steel flower tube and drill the steel flower tube hole; insert the steel cage composed of the main reinforcement and the stirrup into the steel flower tube, the joints are welded firmly, and sink into the drill hole; during the drilling process, if found The offset hole should be backfilled with cement slurry to 300mm ~ 500mm above the offset hole, and then re-drilled to ensure that the s...

Embodiment 2

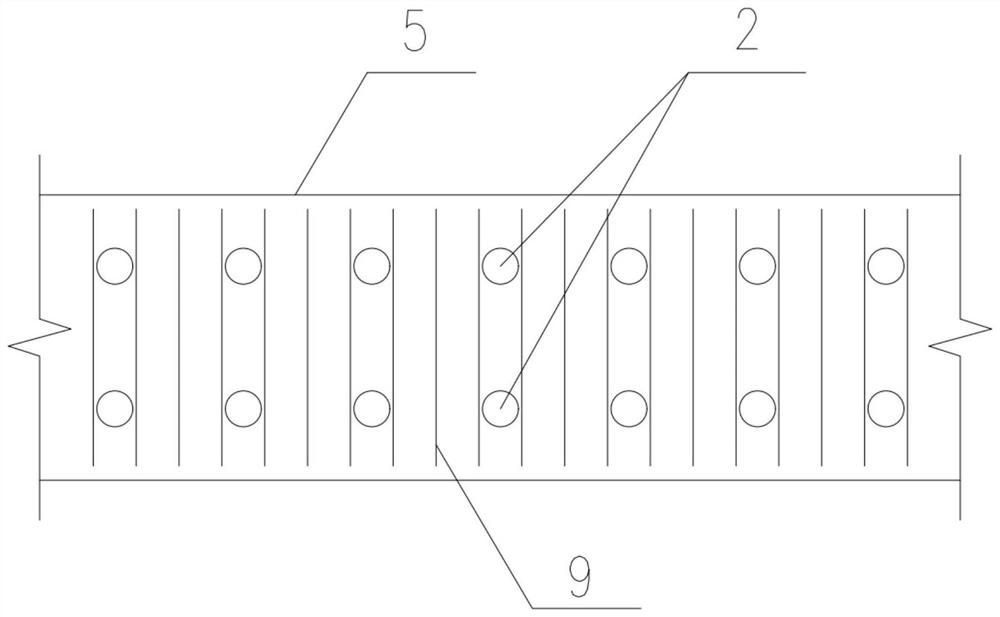

[0052] Compared with Example 1, such as Figure 7 with Figure 8 As shown, the steel floral tubes in Example 2 are arranged in a quincunx shape.

[0053] For a foundation pit with a depth of 10 meters (of which the upper part is 4 meters of plain fill and the lower part is 6 meters of moderately weathered argillaceous siltstone) and 8 meters wide, SMW piles and steel sheet piles should not be used as enclosure structures for the foundation pit. When the foundation pit adopts underground diaphragm wall, bored pile, grading + soil nail wall, and steel pipe pile as the enclosure structure, the earth and stone volume, project cost, land area, and surface settlement comparison are shown in the following table. Among them, the data of the underground diaphragm wall scheme is taken as the base and considered according to 1.

[0054] Scheme comparison Diaphragm Wall drilling piles Grading + Soil Nail Wall Steel pipe pile Earthwork volume 1.00 1.00 2.25 1.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com