Fuel oil system of automobile and leakage detection method of fuel oil system

A fuel system and leak detection technology, applied in the field of vehicles, can solve problems such as false alarms and detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

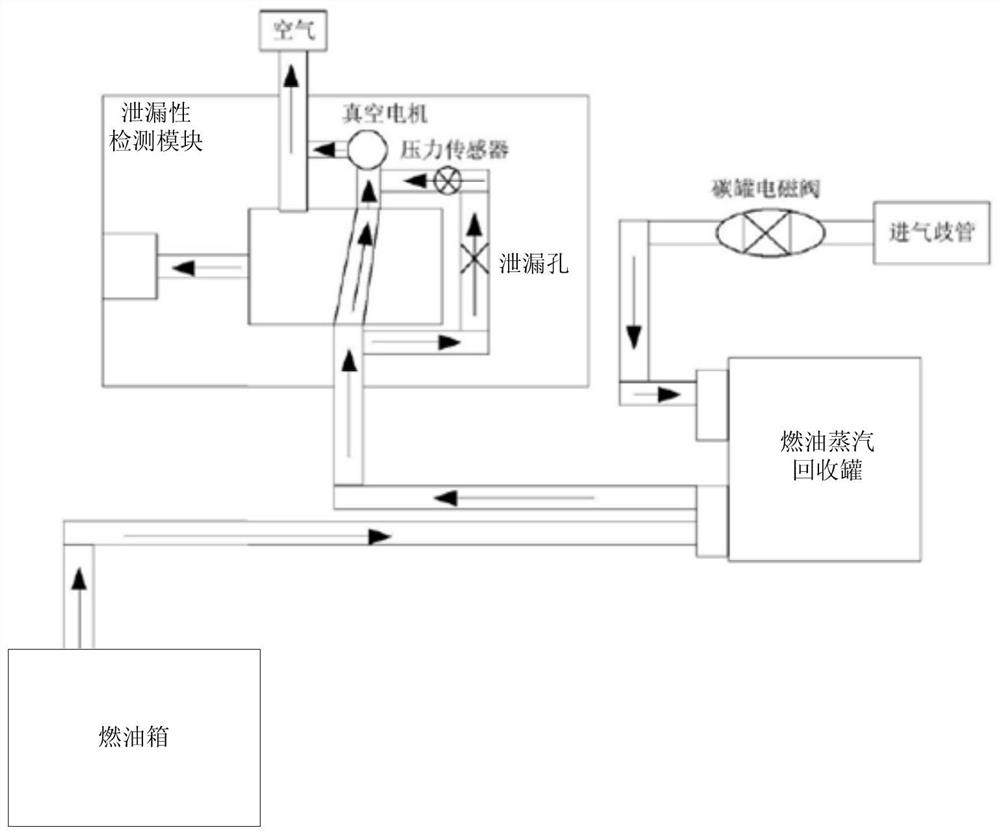

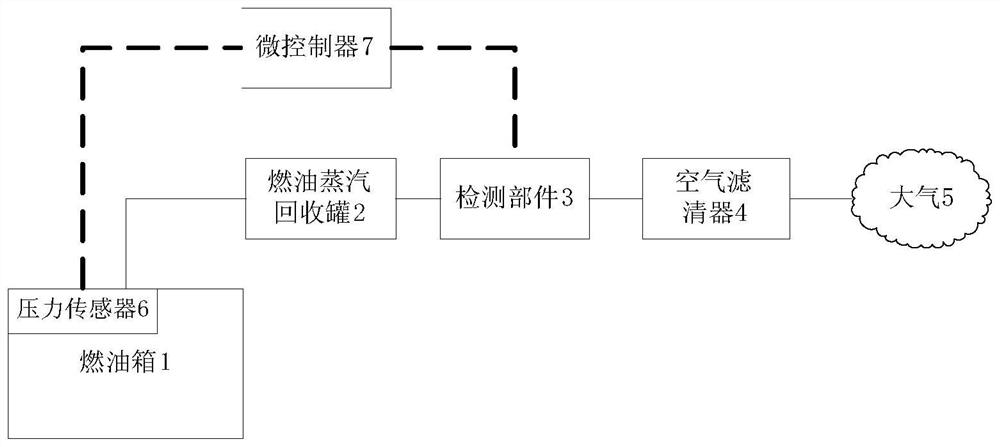

[0041] The automobile of this application includes an engine and a fuel system. Such as image 3 As shown, the fuel system includes a fuel tank 1, a fuel vapor recovery tank 2 and a leak detection device. The fuel tank is connected to the fuel vapor recovery tank, and the fuel vapor recovery tank 2 is provided with an exhaust port. At the same time, the vapor collected in the fuel vapor recovery tank 2 is transported to the engine through pipelines for recycling. There is a pressure sensor on the fuel system.

[0042] As an example, such as image 3 As shown, the pressure sensor 6 is installed in the fuel tank 1 .

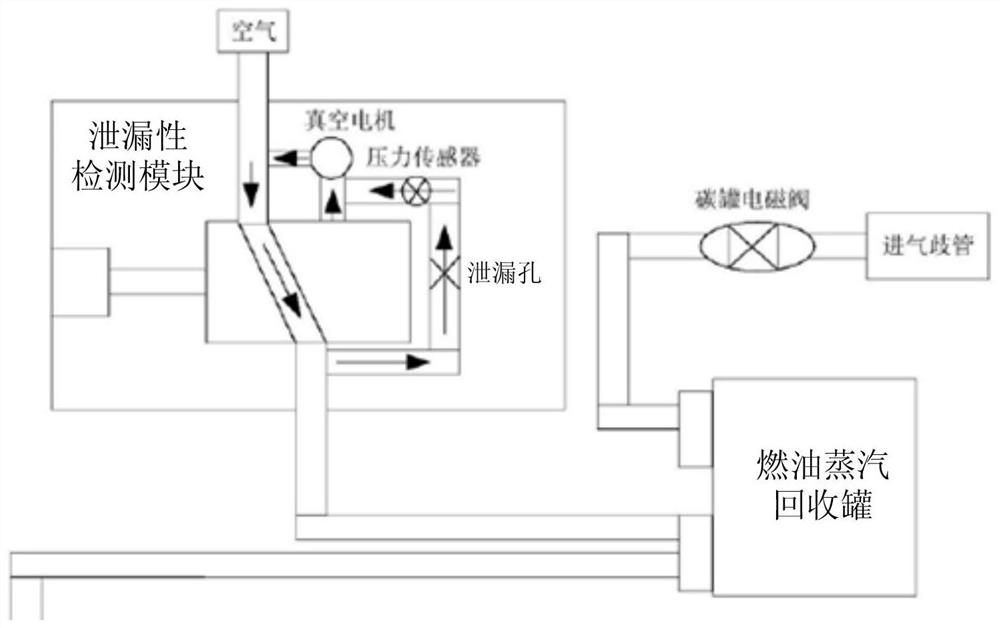

[0043] The leak detection device includes a microcontroller 7 and detection components. The detection components include a pressure regulator and a normally open electromagnetic valve. The air inlet of the normally open electromagnetic valve is connected to the exhaust port of the fuel vapor recovery tank 2. The normally open electromagnetic valve The air outle...

Embodiment 2

[0054] The present application also provides a fuel system leak detection method related to the fuel system of the automobile mentioned above. Such as Figure 8 As shown, the leak detection method includes the following steps:

[0055] S810: Control the normally open solenoid valve to be electrically closed in response to the leakage detection signal, and simultaneously start the pressure regulator to regulate the pressure.

[0056] S820: Stop the pressure regulator in response to the pressure of the fuel system reaching a preset pressure value, and the fuel system enters a pressure maintaining state.

[0057] S830: Collect the pressure signal of the fuel system within a preset time.

[0058] S840: Calculate the difference between the earliest pressure value and the latest pressure value within a preset time, as a pressure change detection value.

[0059] S850: Determine whether the difference between the pressure change detection value and the pressure change standard valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com