Industrial fluid valve

An industrial and fluid technology, applied in the field of industrial fluid valves, can solve problems such as valve stem looseness, poor sealing effect, and fluid overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

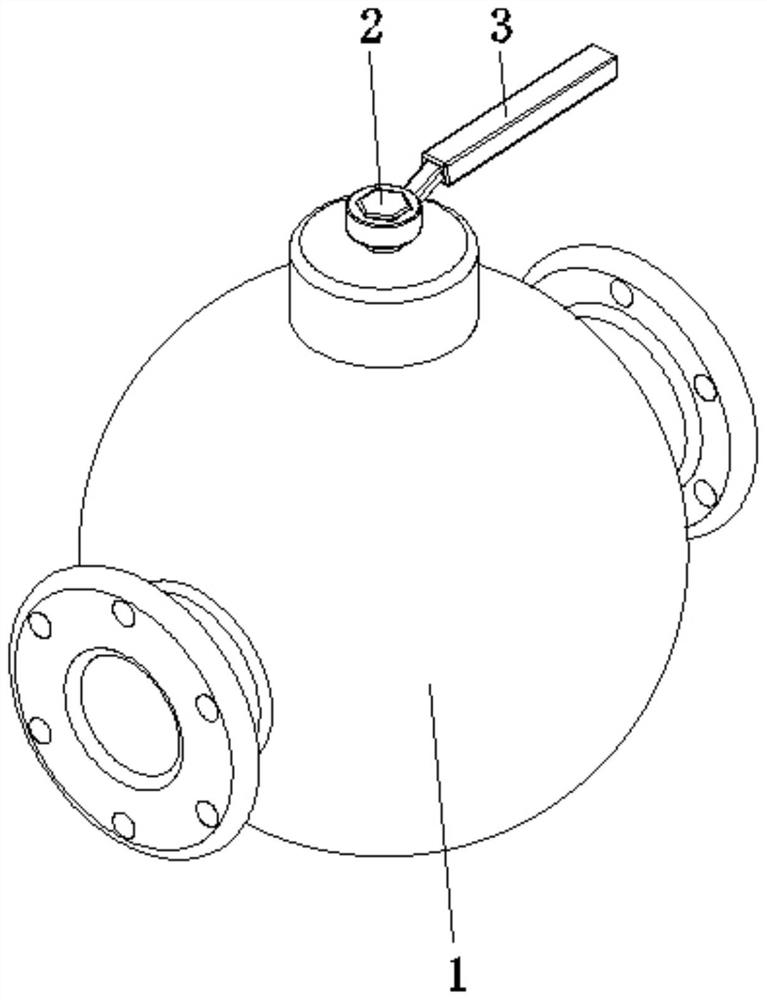

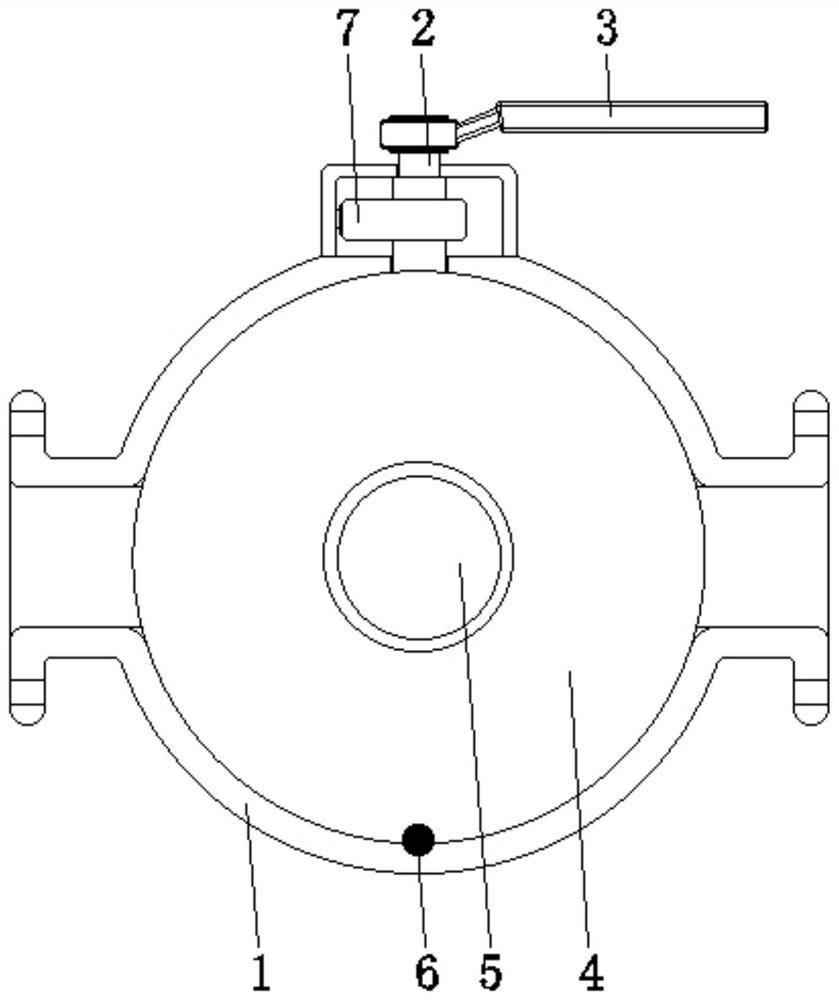

[0034] see Figure 1-8 , the present invention provides a technical solution: an industrial fluid valve, including a valve body 1, a valve stem 2, and a handle 3, the valve stem 2 is rotatably connected to the top center of the valve body 1, and the handle 3 is fixed on the valve stem 2 top;

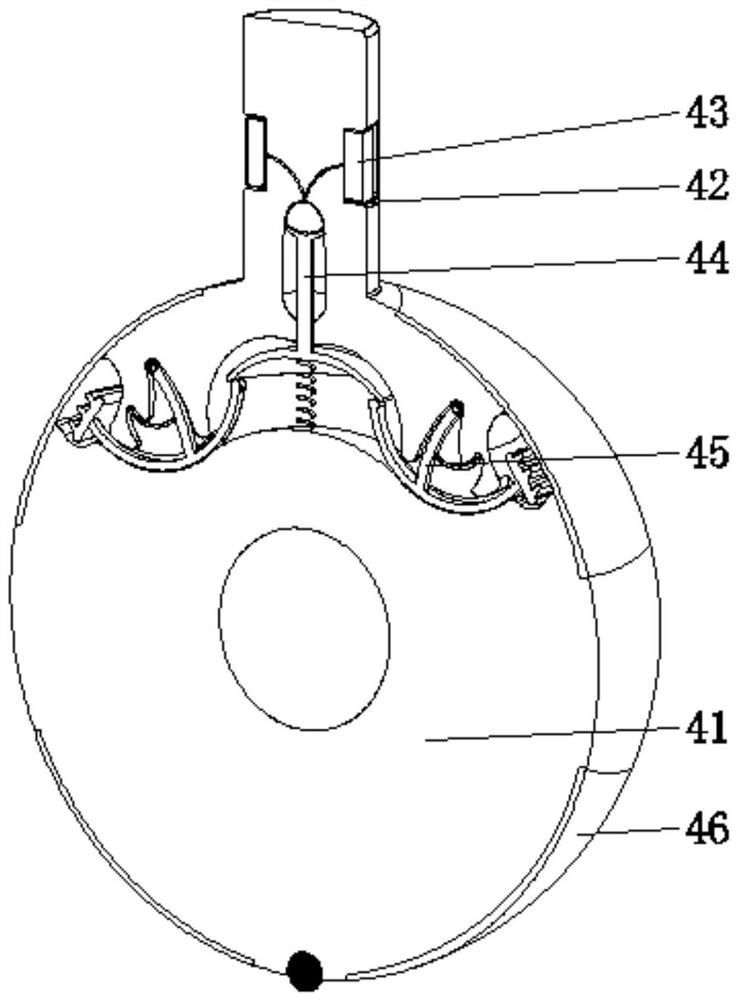

[0035] The inside of the valve body 1 is provided with a spool device 4, a through hole 5, a ball 6, and a clamping device 7. The spool device 4 is arranged inside the valve body 1 and is located at a central position. The bottom end of the valve stem 2 and the spool device The top of 4 is fixedly connected, the through hole 5 is set at the inner center of the valve core device 4, the ball 6 is set at the bottom center of the valve core device 4 and is connected with the bottom of the inner wall of the valve body 1, and the clamping device 7 is set on the valve body. The top of the body 1 is connected with the valve stem 2, and the valve stem 2 is clamped by the clamping device 7, so as...

Embodiment example 2

[0041] The clamping device 7 is provided with a connection block 71, an elastic caliper 72, and an arc protrusion 73. The surface side of the connection block 71 is fixedly connected with the top side of the valve body 1, and the elastic caliper 72 is fixed on the surface side of the connection block 71. , the arcuate protrusions 73 are fixed on the corresponding two sides of the inner wall of the elastic caliper 72. When the clamping device 7 is stuck on the surface of the valve stem 2, the elastic calipers 72 provide the clamping force, and the arcuate protrusions 73 and the limit concave The groove 42 cooperates to increase the contact area, avoid shaking, improve stability, and at the same time increase the contact area, so that the elastic air bag 43 outside the valve stem 2 is completely squeezed, which helps to be inside the valve stem 2 The elastic airbag 43 inflates rapidly, thereby increasing the driving force, helping to improve the sealing effect and reduce the leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com