Part repairing workbench and workbench using method

A workbench and parts technology, which is applied in the field of parts repair workbench, can solve the problems of large influence on measurement accuracy, poor measurement stability, and low measurement efficiency, so as to improve efficiency, facilitate repair operations, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

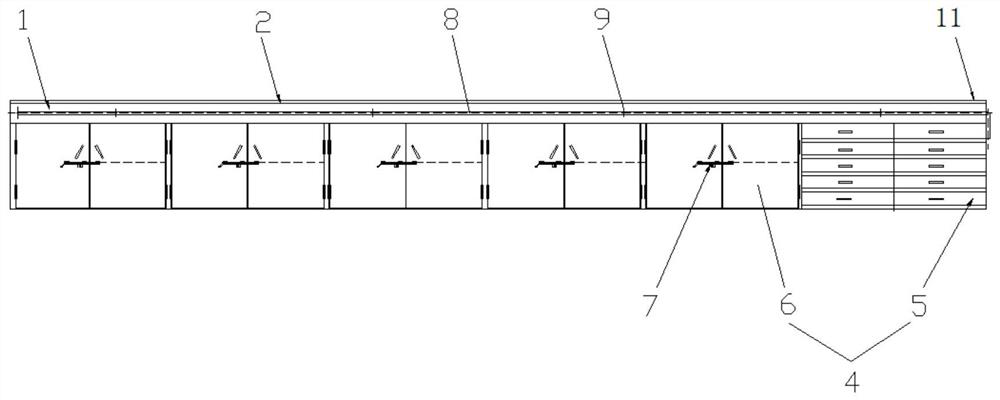

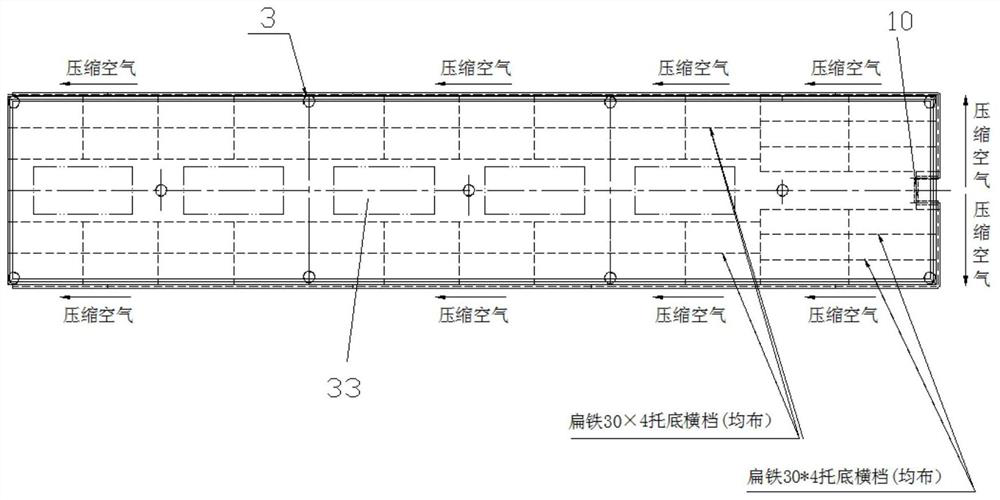

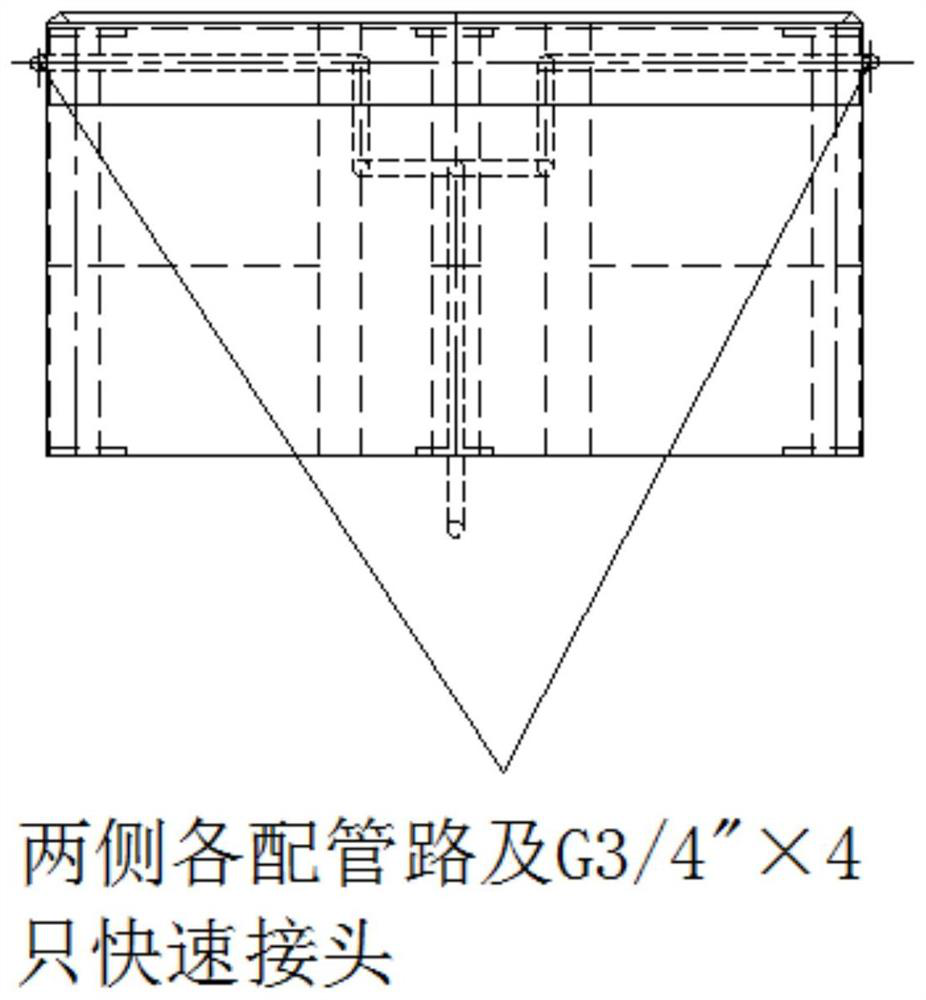

[0035] Such as Figures 1 to 4 Shown is an embodiment of a part repair workbench of the present invention, which includes a main body 1 of the worktop, a stainless steel cladding plate 2 laid on the main body 1 of the worktop to form the surface of the repair workbench, and a workbench arranged under the main body 1 of the worktop. A table column 3, a number of tool cabinets 4 are arranged adjacent to the bottom of the table main body 1 in turn; wherein, at least one tool cabinet 4 in the tool cabinet 4 is set to a drawer-type tray 5 structure; except for the drawer-type tray 5 Outside the tool cabinet 4 of the structure, the remaining tool cabinets 4 adopt a double-open or single-open cabinet door 6 structure, and the double-open or single-open cabinet door 6 structure is provided with a cabinet door handle lock pin attachment 7; A compressed air pipeline 8 is arranged on the circumferential side of the main body 1 , and a number of quick connectors 9 are arranged at interval...

Embodiment 2

[0048] A method for using the workbench using the part repair workbench of Embodiment 1, including using the pneumatic go-no-go gauge unit 12 on the repair station to quickly detect the inner hole of the part 35, and the detection method is as follows:

[0049] (1) Calibration before measurement: According to the part 35 to be tested, select the calibration comparison circle 27 corresponding to the inner diameter of the same specification, insert the cylindrical pneumatic probe 15 into the inner hole of the calibration comparison circle 27, and perform the cylindrical pneumatic probe 15 The accuracy correction;

[0050] (2) Parts installation: the parts to be detected are placed in the detection position of the repair station, so that the telescopic rod 17 of the servo electric push rod 16 is placed in the approximate central part of the inner hole of the part, and a block 24 of equal height is placed under the part if necessary; Adjust the height of the top of the telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com