Testing equipment and testing method for mobile phone circuit chip

A technology of circuit chips and testing equipment, which is applied in the field of testing equipment for mobile phone circuit chips, and can solve problems such as poor contact detection results, errors, and insufficient contact between chips and probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

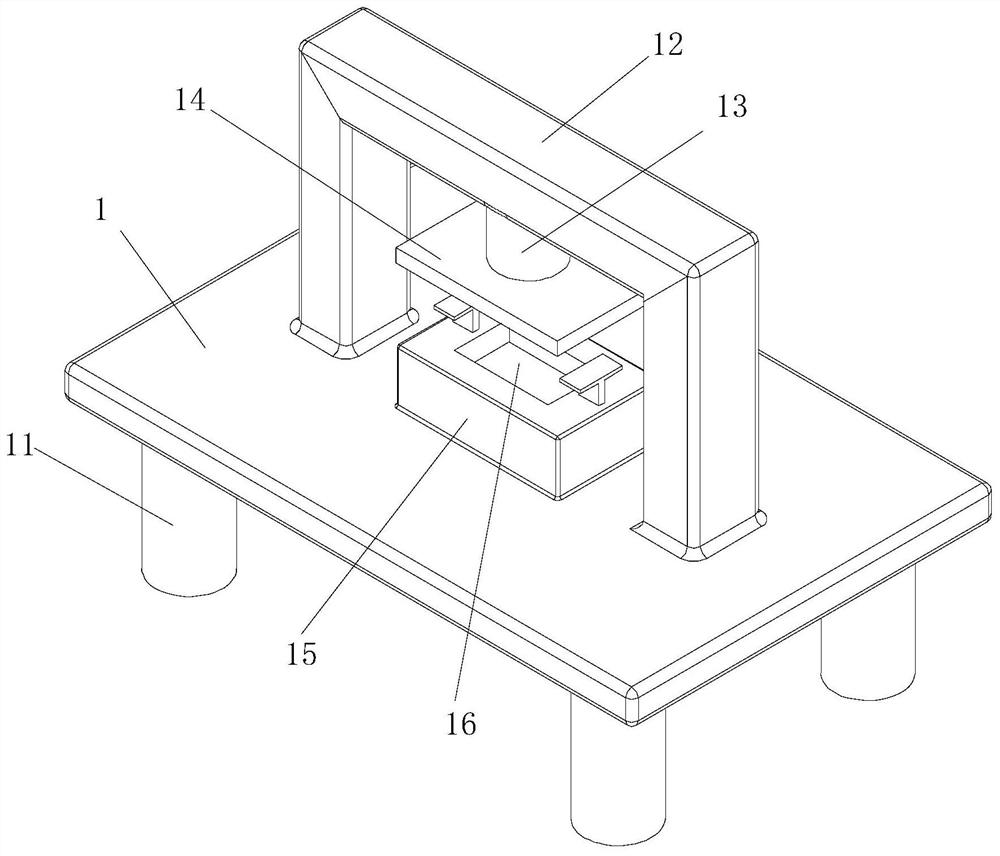

[0036] Such as Figure 1 to Figure 6 As shown, the testing equipment of a kind of mobile phone circuit chip of the present invention, comprises fixed plate 1; Described fixed plate 1 bottom end is affixed with a group of legs 11; Described fixed plate 1 is affixed with bracket 12; The support 12 is an inverted U-shaped support 12; the center of the bottom end of the support 12 is affixed with a first cylinder 13; the output end of the first cylinder 13 is affixed with an upper detection seat 14; the fixed plate 1 is relatively The position of the upper detection seat 14 is fixedly connected with the lower detection seat 15; the top of the lower detection seat 15 is provided with a placement groove 16; the lower detection seat 15 is provided with a first cavity 19; the first cavity 19 Located below the placement groove 16; the inner wall of the first cavity 19 is slidably connected with a motherboard 191; the top of the motherboard 191 is fixed with a probe 192; the bottom of t...

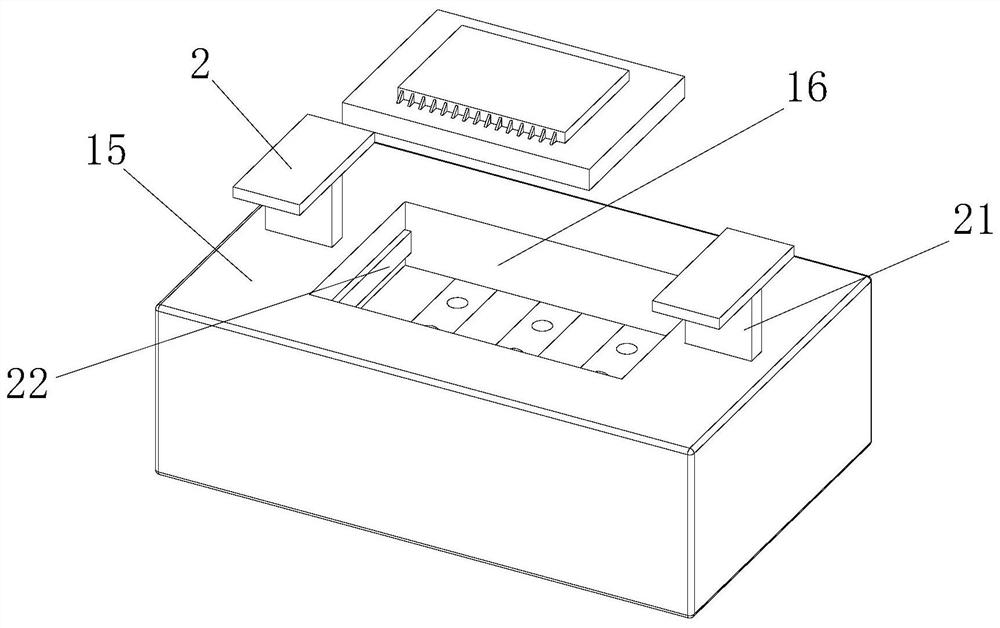

Embodiment approach

[0037] As an embodiment of the present invention, a pair of lower pressure grooves symmetrical to the placement groove 16 are opened on the top of the lower detection seat 15; A trapezoidal plate 21 is fixedly connected to the end, and the sloped end of the trapezoidal plate 21 extends into the first cavity 19; the sidewalls on both sides of the placement groove 16 are fixedly connected with a positioning plate 22 by a spring, and the side walls of the positioning plate 22 A push post 23 is fixedly attached to the wall; the end of the push post 23 away from the position adjustment plate 22 extends into the first cavity 19, and the end of the push post 23 contacts with the slope of the trapezoidal plate 21; during work, Generally, the size of the placement groove 16 is set to be the same as the size of the chip, which is convenient for the alignment detection of the probe 192 and the chip, but it is necessary to set up a take-out assembly to take it out, which increases the cost...

Embodiment 2

[0044] Such as Figure 7 to Figure 8Shown, a kind of testing equipment of mobile phone circuit chip of the present invention, all offer through groove 5 on the two side walls of described corrugated groove 3 bosses, and through groove 5 and through cavity 38 communicate with each other; Described through groove 5 is fixedly connected with a fixed rod 51, and the center of the fixed rod 51 is rotatably connected with a first rotating shaft 52; There is a first gear 53; the push rod 39 is affixed with a rack layer on the side wall close to the first gear 53; the first gear 53 and the rack layer are meshed with each other; during work, the push rod 39 is on the second When the roller 37 and the vertical plate 34 move back and forth, the push rod 39 can drive the first rotating shaft 52 to rotate through the mutual engagement of the rack layer and the first gear 53, and the rotation of the first rotating shaft 52 can drive the fan blade The 54 rotation can not only drive the rapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com