Function test system and method for locking assembly

A functional testing and assembly technology, applied in electronic circuit testing, printed circuit testing, electrical measurement, etc., can solve the problems of not considering the working conditions of the product, low test reliability, and small test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

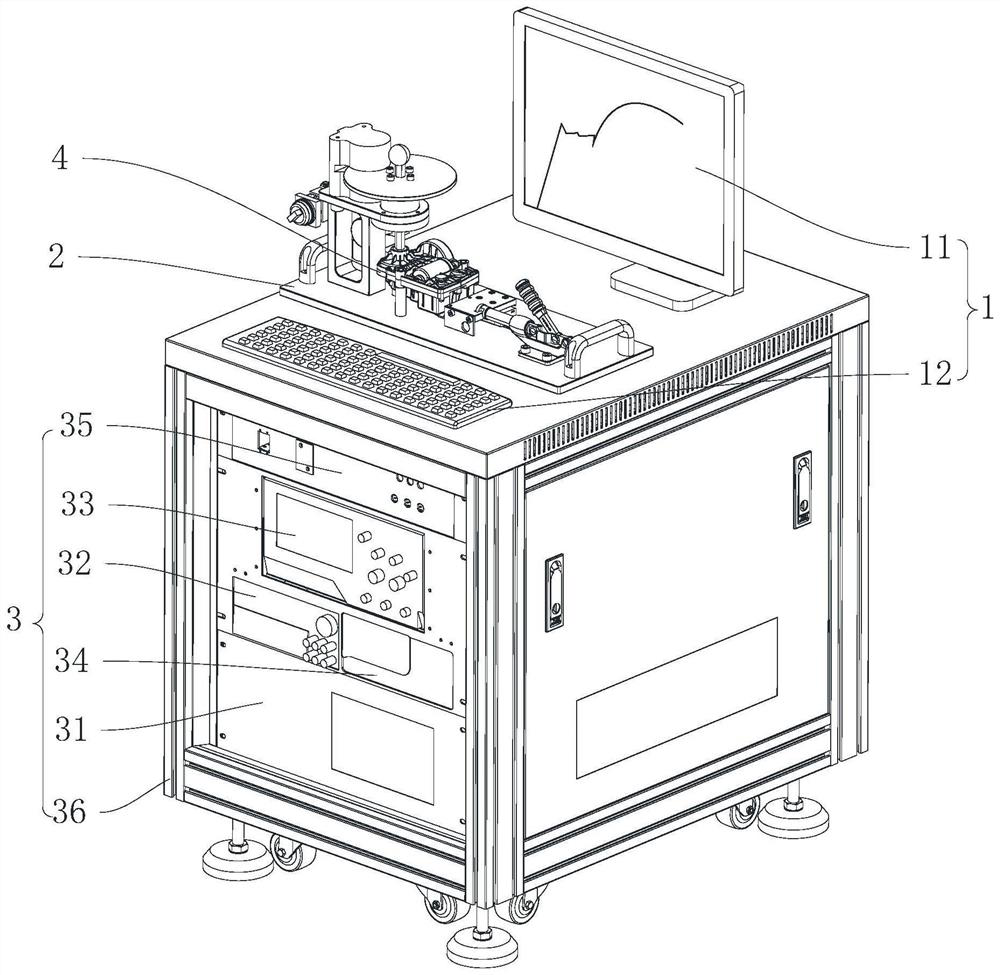

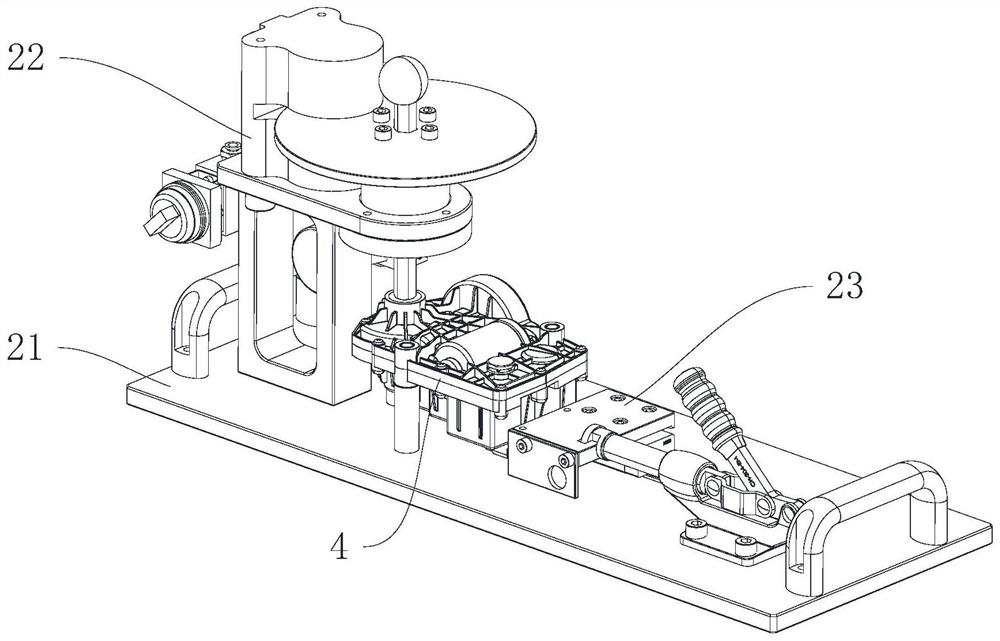

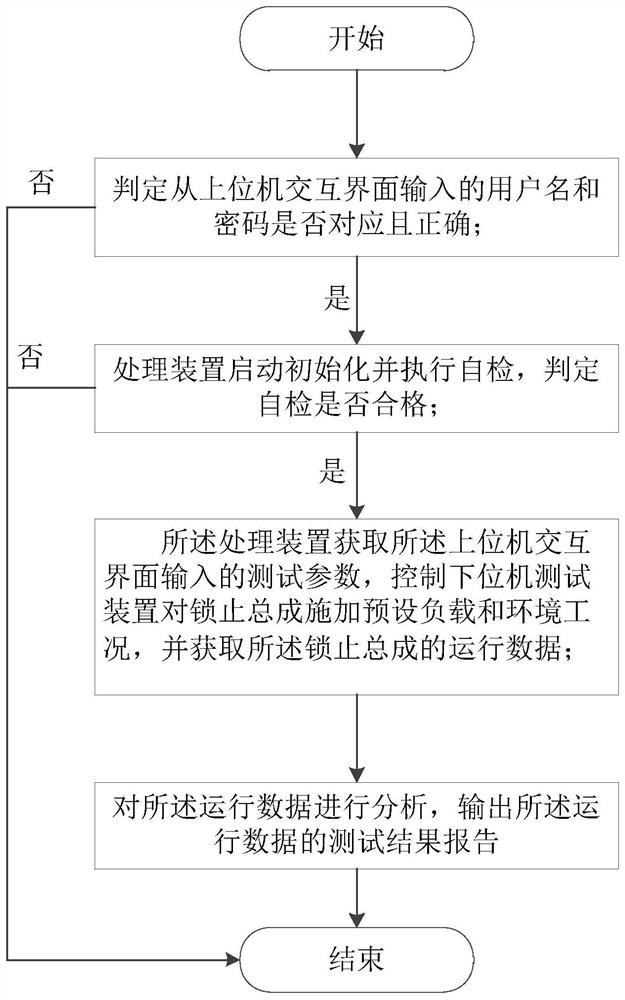

[0060] Refer below Figure 1-Figure 4 A functional testing system and method of a locking assembly according to a specific embodiment of the present invention are described.

[0061] The functional testing system of the locking assembly in this embodiment includes an upper computer interaction interface 1 , a lower computer testing device 2 and a processing device 3 .

[0062] The upper computer interaction interface 1 is used to receive the user name, password and test parameters input by the user. The host computer interaction interface 1 is preset with multiple sets of user data, each set of user data corresponds to a set of test parameter settings, and each set of test parameters corresponds to a preset load and environmental working condition. The host computer interaction interface 1 includes a display 11 and a keyboard and mouse device 12 .

[0063] The lower computer test device 2 is used to receive test parameters and apply preset loads and environmental conditions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com