High resilience titanium alloy tube intelligent forming method and system

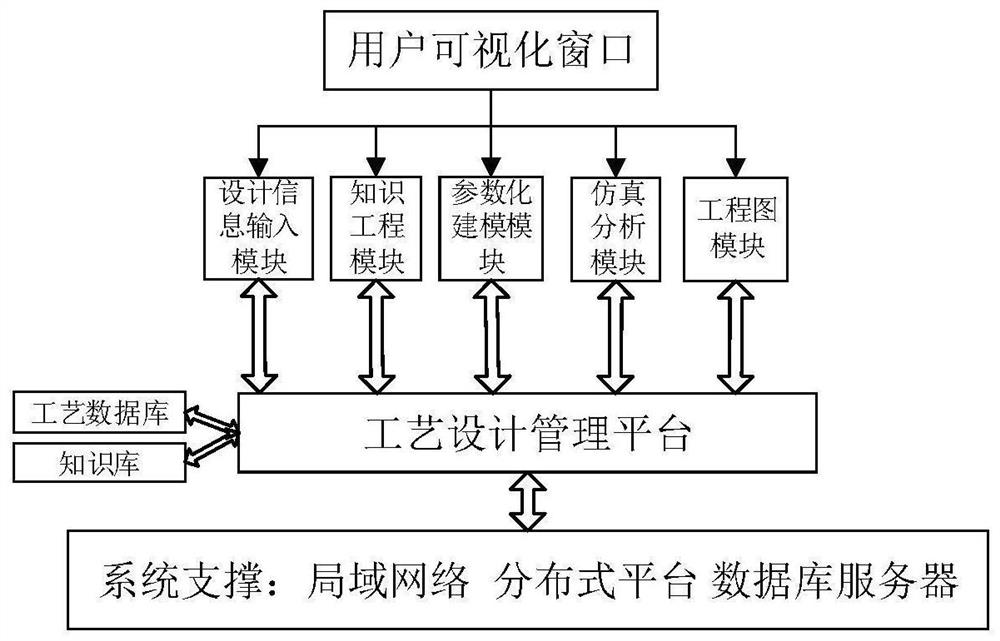

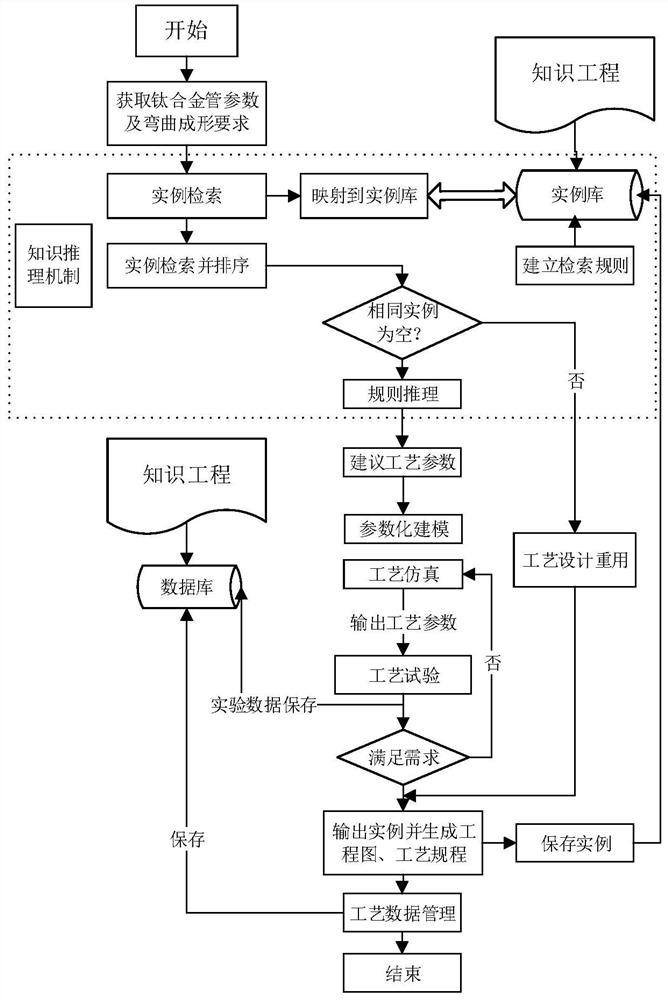

A titanium alloy tube, high-rebound technology, applied in machine learning, instrumentation, geometric CAD and other directions, can solve the problems of not referring to the titanium alloy tube bending forming process design system, system optimization, and no process simulation module, etc., to improve Process R&D efficiency, reduced test times, and rapid generation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the terms "comprising" or "may include" that may be used in various embodiments of the present invention indicate the existence of invented functions, operations or elements, and do not limit the existence of one or more functions, operations or elements. Increase. In addition, as used in various embodiments of the present invention, the terms "comprising", "having" and their cognates are only intended to represent specific features, numbers, steps, operations, elements, components or combinations of the foregoing, And it should not be understood as first excluding the existence of one or more other features, numbers, steps, operations, elements, components or combinations of the foregoing or adding one or more features, numbers, steps, operations, elements, components or a combination of the foregoing possibilities.

[0043] In various embodiments of the present invention, the expression "or" or "at least one of A or / and B" includes any or all combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com