Preparation method and application of solid electrolyte polymer modified by gas phase permeation method

A solid-state electrolyte, gas-phase infiltration technology, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problems of poor dispersion uniformity, reduced surface performance, weak interaction force, etc., to achieve low difficulty and reduce interface. resistance, the effect of increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation of solid electrolyte polymer modified by gas phase infiltration method:

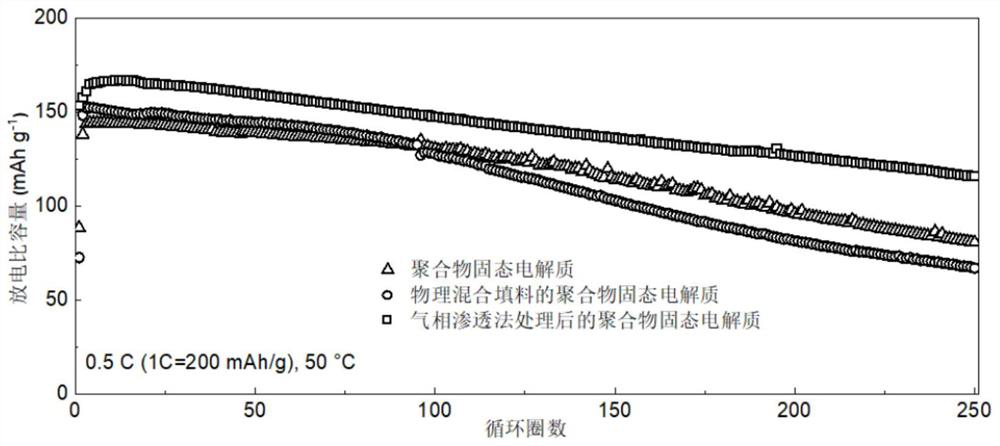

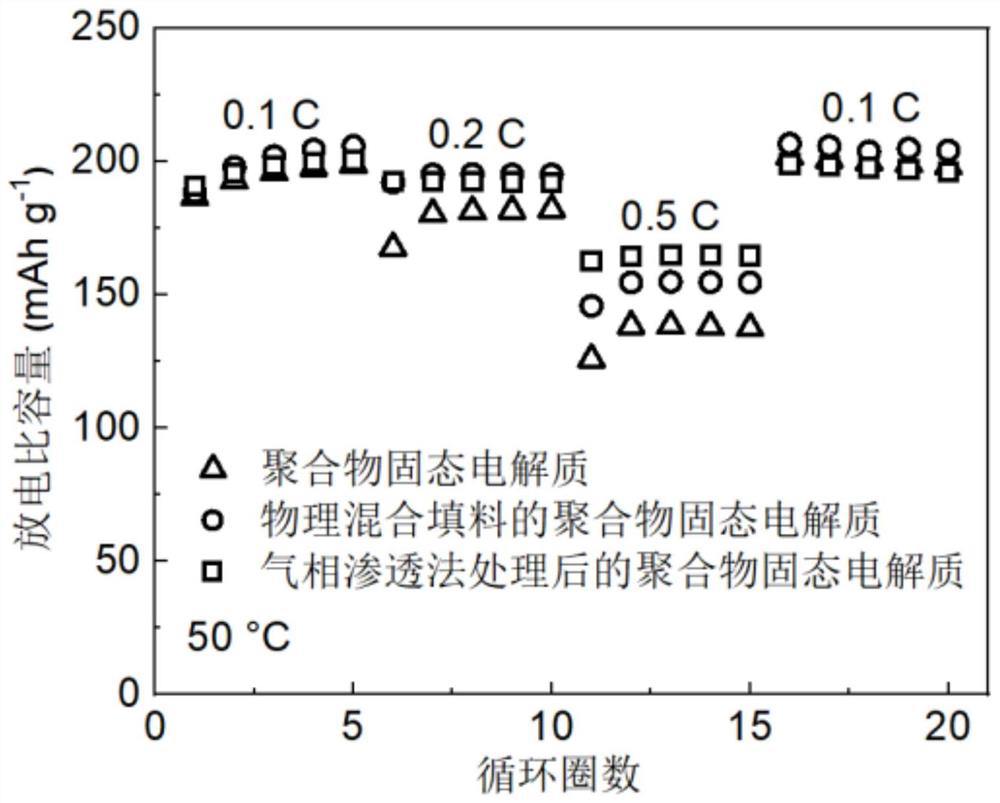

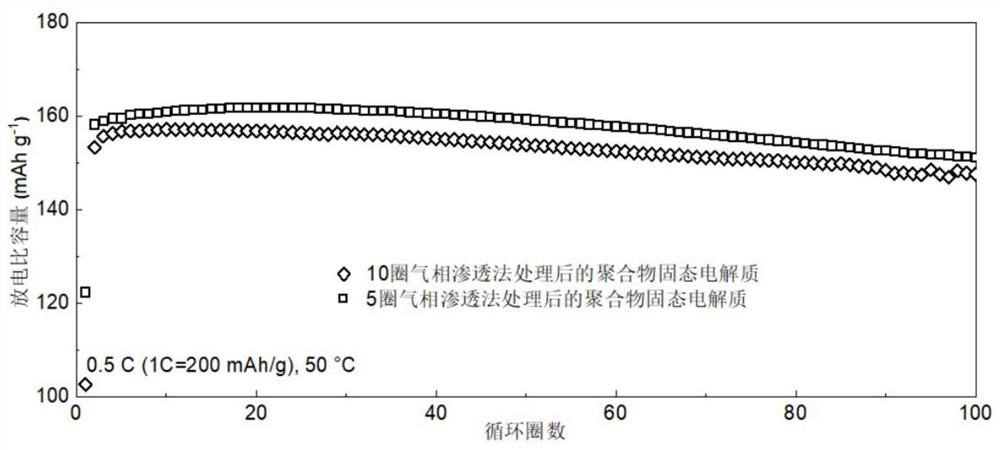

[0023] Vapor phase infiltration method can be realized by atomic layer deposition equipment, put polyethylene oxide (PEO) powder in the sample barrel for heating and preheating and at the same time mechanically stir or vibrate for 1-2h, and then follow the diethyl zinc The mass ratio of zinc to the solid electrolyte polymer is 1% and the molar ratio of diethylzinc and deionized water is 0.75:1, and the chemical precursor source diethylzinc is alternately fed to make polyethylene oxide Alkanes adsorb diethyl zinc; pass inert gas high-purity argon for purging; then pass through chemical precursor source deionized water to make zinc oxide nanoparticles inside the polymer; finally pass high-purity argon for purging, The modified solid electrolyte polymer was obtained after 10 cycles of gas phase infiltration. The mass fraction of Zn in the material was 6 wt%, and the correspondin...

Embodiment 2

[0034] A kind of preparation of solid electrolyte polymer modified by gas phase infiltration method:

[0035] Vapor phase infiltration method can be realized by atomic layer deposition equipment, put polyethylene oxide (PEO) powder in the sample barrel for heating and preheating and at the same time mechanically stir or vibrate for 1-2h, and then follow the diethyl zinc The mass ratio of zinc to the solid electrolyte polymer is 1% and the molar ratio of diethylzinc and deionized water is 0.75:1, and the chemical precursor source diethylzinc is alternately fed to make polyethylene oxide Alkanes adsorb diethyl zinc; pass inert gas high-purity argon for purging; pass in chemical precursor source deionized water to generate zinc oxide nanoparticles inside the polymer; then pass inert gas high-purity argon for purging; The modified solid electrolyte polymer was obtained after 5 cycles of the gas phase infiltration cycle. The mass fraction of Zn in this material was measured to be 2...

Embodiment 3

[0046] A kind of preparation of solid electrolyte polymer modified by gas phase infiltration method:

[0047] Vapor phase infiltration method can be realized by atomic layer deposition equipment, put polyethylene oxide (PEO) powder in the sample barrel for heating and preheating and at the same time mechanically stir or vibrate for 1-2h, and then follow the diethyl zinc The mass ratio of zinc to the solid electrolyte polymer is 1% and the molar ratio of diethyl zinc to deionized water is 0.5 to 1:1, and the chemical precursor source diethyl zinc is alternately introduced to make the polycyclic Oxyethane adsorbs diethyl zinc; pass inert gas high-purity argon for purging; pass in chemical precursor source deionized water to make zinc oxide nanoparticles inside the polymer; then pass inert gas high-purity argon for blowing Sweep; After 15 cycles of the above-mentioned gas phase infiltration cycle, the modified solid electrolyte polymer is obtained. The mass fraction of Zn measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com