PCB unlocking jig

A PCB board and fixture technology, applied in the field of PCB unlocking fixtures, can solve the problems of easily damaged PCB boards, affecting product quality, and low transfer efficiency, so as to ensure product quality, protect against damage, and quickly transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

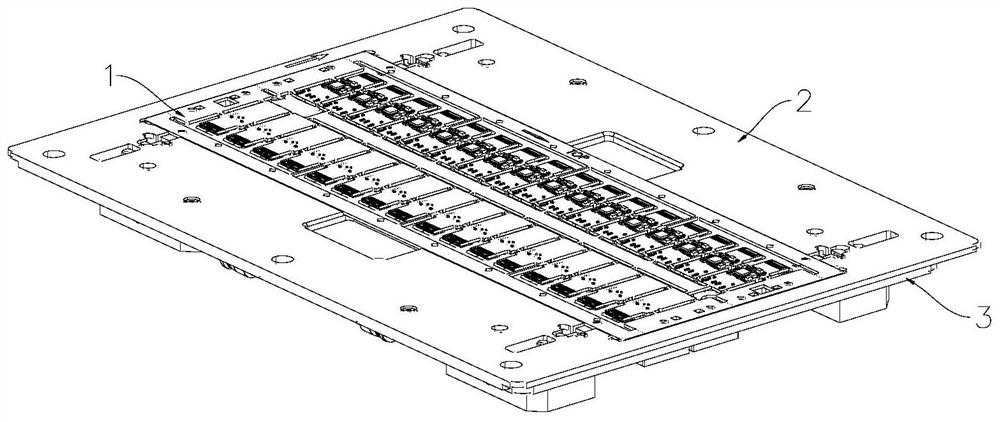

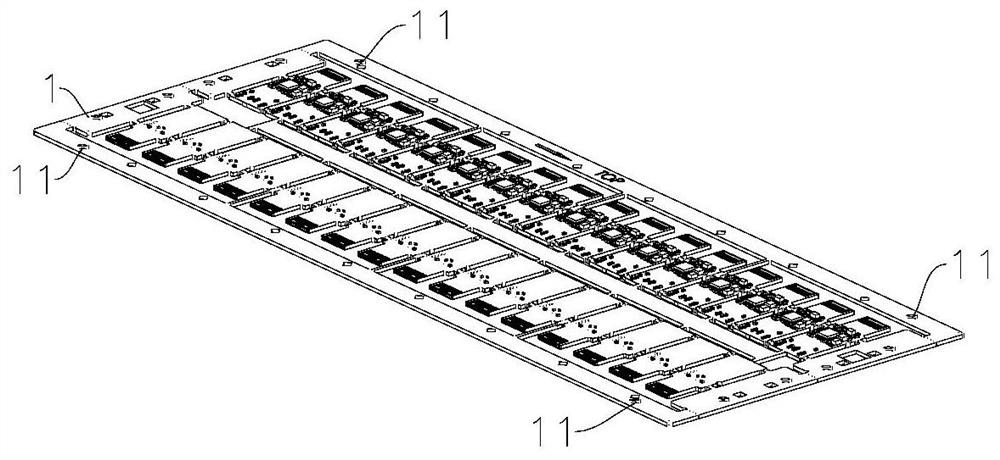

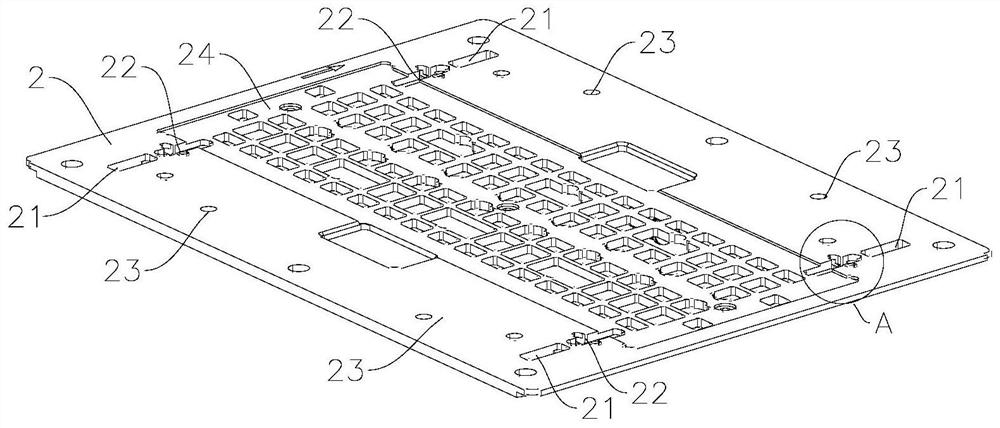

[0029] figure 1 , Figure 9 and Figure 10 A PCB unlocking jig shown includes a jig unlocking device 3 and a spring patch jig 2 arranged on the top of the jig unlocking device 3; image 3 As shown, the top surface of the spring patch fixture 2 is provided with a cavity 24 for placing the PCB board 1, the cavity 24 has a rectangular structure, and the top surface of the spring patch fixture 2 is located on two sides of the cavity 24. The outer part of the long side is provided with four elongated upper stroke holes 21 connected up and down, and the four upper stroke holes 21 correspond to the four corners of the cavity 24 respectively; Figure 5 shown and Figure 6 As shown, the position corresponding to the upper stroke hole 21 on the fixture unlocking device 3 is provided with a long strip-shaped lower stroke hole 31 connected up and down, and an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com