Posterior ankle bone fracture plate

A bone plate and distal technology, applied in the field of medical devices, can solve the problems of insufficient fixation strength, inability to fix comminuted fractures of the posterior malleolus, and no standard treatment plan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

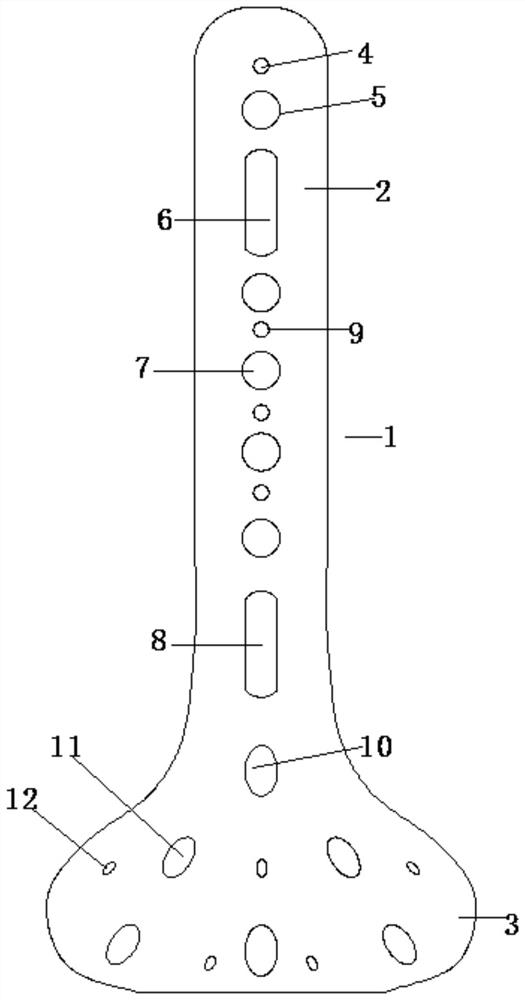

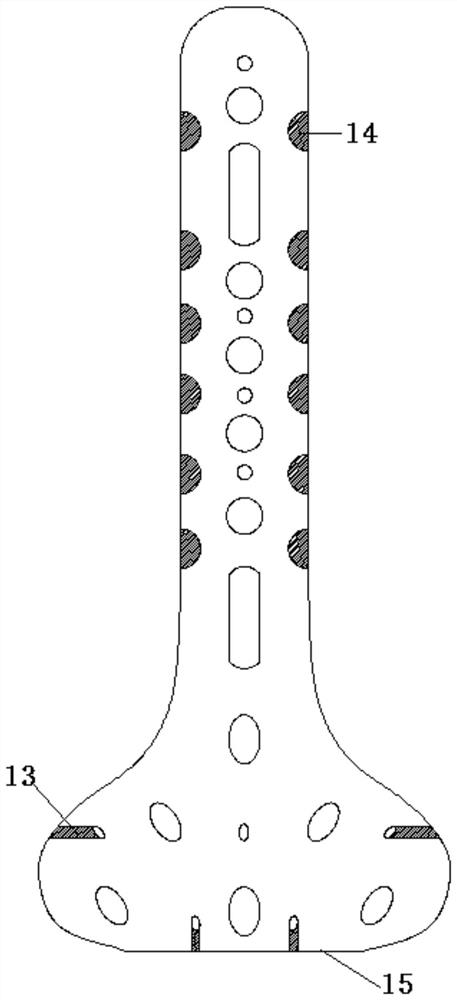

[0018] Such as Figure 1-Figure 3 A posterior malleolus bone plate is shown, comprising a bone plate body 1, the bone plate body 1 has a T-shaped structure as a whole, and the bone plate body 1 is divided into a proximal bone plate 2 and a distal bone plate 3. The distal bone plate 3 is an arc-shaped structure, extending curvedly to both sides. The proximal bone plate 2 and the distal bone plate 3 are smoothly transitioned and connected, forming an integrated structure. The middle part of the proximal bone plate 2 is from top to bottom. There are proximal Kirschner wire hole 4, proximal locking hole 5, sliding hole 6, proximal locking hole I7, and sliding hole I8 in sequence, and there are proximal Kirschner wire holes I9 between adjacent locking holes I7 , the proximal Kirschner wire hole 4 can be used for temporary fixation, and the sliding hole 6 is used for temporary pressurization and fixation of the proximal end of the bone plate through cortical bone screws, so that the...

Embodiment 2

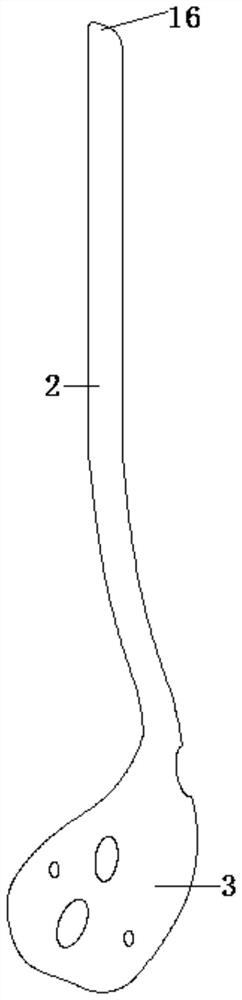

[0020] Such as Figure 1-Figure 3 A posterior ankle bone plate is shown, including a bone plate body 1, which is a T-shaped structure as a whole, and the edge of the bone plate body is a smooth curved surface structure, which reduces friction with soft tissue and reduces postoperative discomfort. , the bone plate body 1 is divided into a proximal bone plate 2 and a distal bone plate 3, the distal bone plate 3 is an arc-shaped structure extending to both sides, the proximal bone plate 2 and the distal bone plate The plates 3 are smoothly transitioned and connected, and have an integrated structure. The upper end surface of the proximal bone plate 2 is a bevel structure 16, which facilitates the insertion of the bone plate, facilitates the operation of the operator, and reduces soft tissue irritation. In the middle part, there are proximal Kirschner wire hole 4, proximal locking hole 5, sliding hole 6, proximal locking hole I7 and sliding hole I8 in order from top to bottom. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com