Disinfection device for medical drill bit of orthopedic instrument

A technology of disinfection device and equipment, which is applied in the directions of disinfection, heating device, water supply device, etc., to achieve the effect of improving disinfection efficiency, increasing disinfection area and drying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

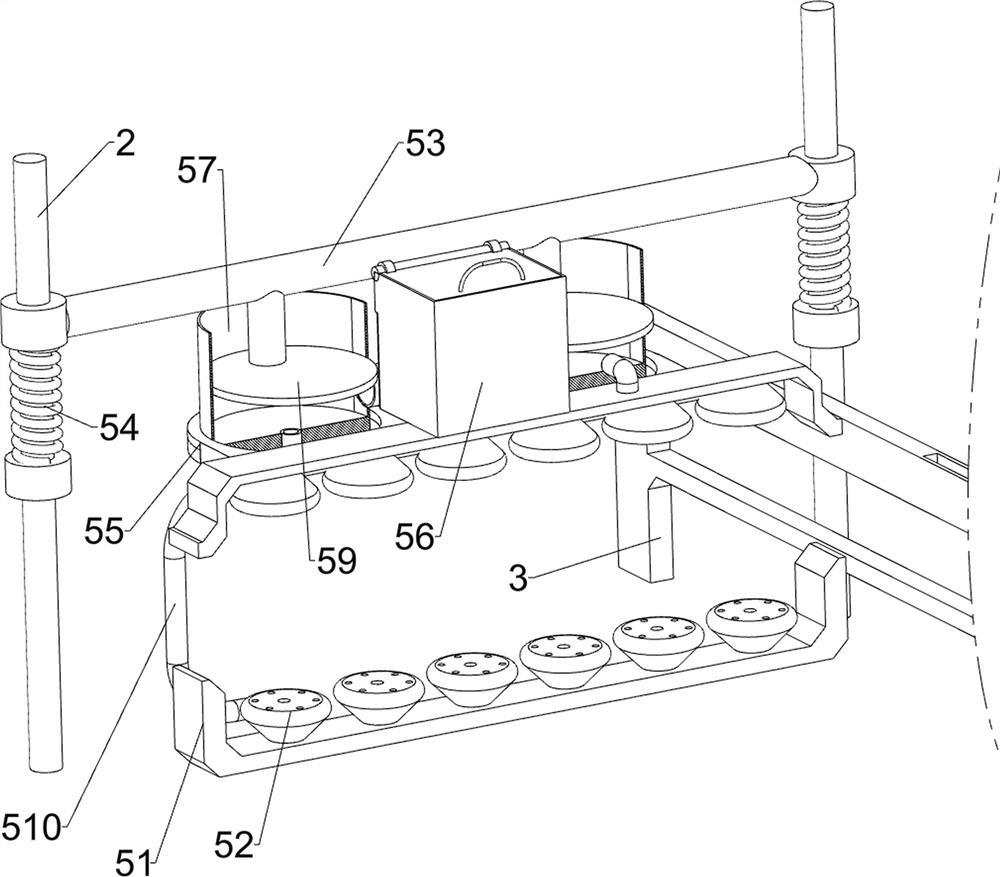

[0030] A device for sterilizing medical drills for orthopedic instruments, such as Figure 1-4 As shown, it includes a base 1, a guide rod 2, a guide plate 3, a clamping mechanism 4 and a pressure spray assembly 5. Two guide rods 2 are symmetrically connected to the right side of the top of the base 1, and the front and rear sides of the top of the base 1 are connected There is a guide plate 3, a clamping mechanism 4 is arranged on the front side guide plate 3, and a pressure spray assembly 5 is arranged between the two guide plates 3.

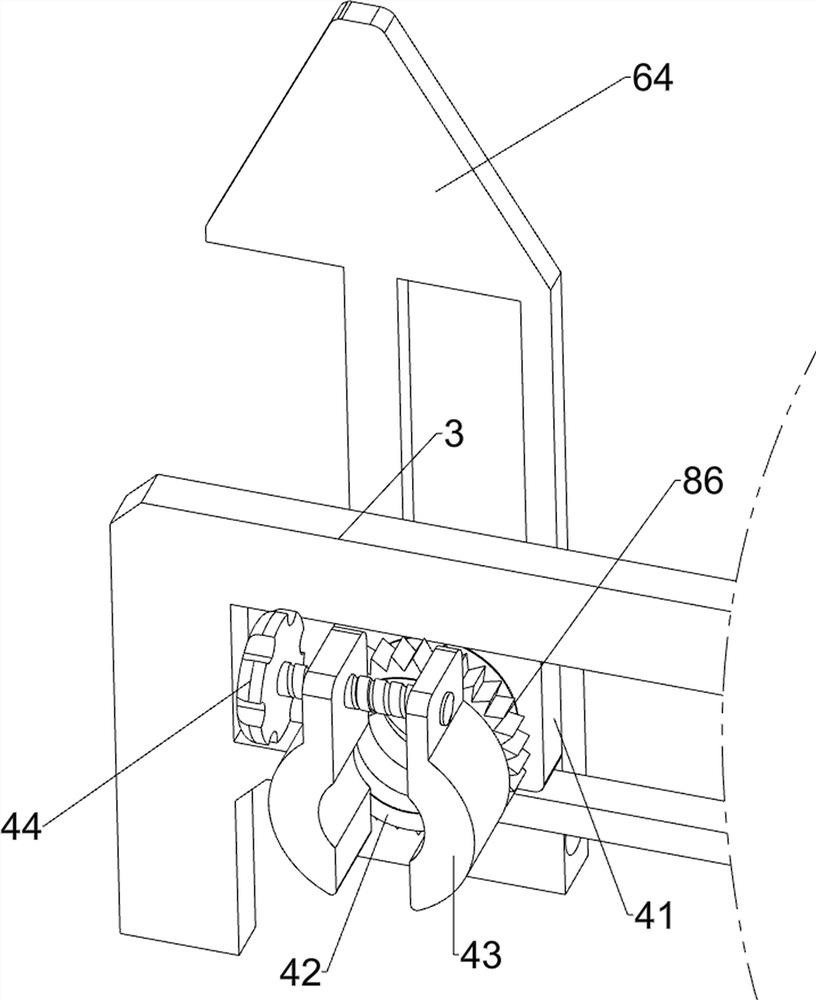

[0031] The clamping mechanism 4 includes a block 41, a rotating rod 42, a clamping plate 43 and a first screw rod 44, the front side guide plate 3 is slidably connected with a block 41, and the block 41 is rotatably connected with a rotating rod 42, and the rotating rod 42 The rear side is connected with a splint 43 , the splint 43 is rotatably connected with a first screw rod 44 , and the first screw rod 44 is connected with a clamping block ...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 and Figure 5 As shown, a driving mechanism 6 is also included, and the driving mechanism 6 includes a servo motor 61, a second screw rod 62, a connecting block 63 and a first wedge block 64, and a bearing seat is connected to the right side of the front side of the front side guide plate 3, and the bearing seat A second screw rod 62 is connected inside, a servo motor 61 is installed on the left front side of the top of the base 1, the output shaft of the servo motor 61 is connected to the left end of the second screw rod 62, and a connection block 63 is connected to the second screw rod 62 by means of threaded connection , the connecting block 63 is fixedly connected with the clamping block 41 , the top of the connecting block 63 is connected with a first wedge-shaped block 64 , and the first wedge-shaped block 64 cooperates with the slide bar 53 .

[0036]When the medical drill bit is to be sterilized, the servo motor 61 ca...

Embodiment 3

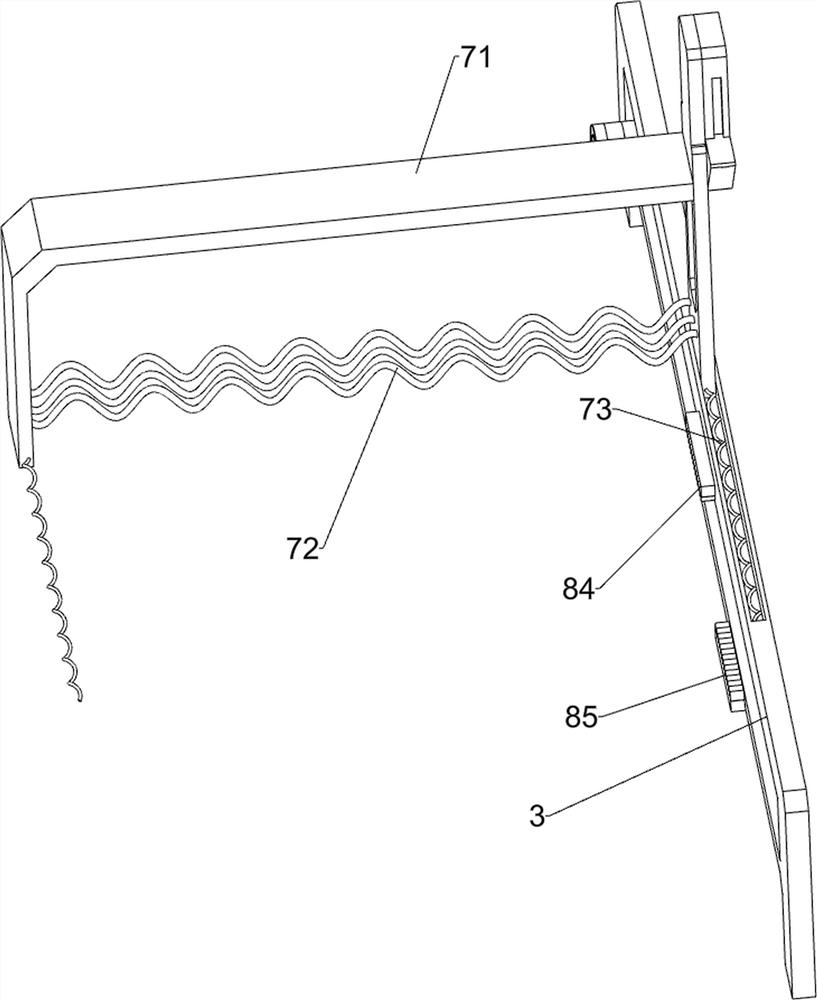

[0038] On the basis of Example 2, such as figure 1 , Figure 5 and Figure 6 As shown, a drying mechanism 7 is also included. The drying mechanism 7 includes a sliding frame 71, a heat pipe 72 and a second return spring 73. A sliding frame 71 is slidably connected between the tops of the two guide plates 3. The sliding frame 71 A plurality of heating tubes 72 are connected to the lower part, and a second return spring 73 is connected between the carriage 71 and the guide plate 3 .

[0039] When the medical drill bit moves to the left, the heating tube 72 can be opened, and the heating tube 72 can generate heat, so that the medical drill bit can be sterilized for the second time, and the disinfectant on the medical drill bit can be dried, and when the medical drill bit moves to the left, , the carriage 71 can be pushed to the left, and the second return spring 73 is compressed accordingly, so that the heating tube 72 can move to the left. After the medical drill is dried, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com