Pointing process and device beneficial to drawing and die penetrating of steel wire

A steel wire and rolling tip technology, applied in the field of steel wire drawing and piercing, can solve the problems of low production efficiency, long rolling time, increased rolling burrs, etc., and achieve the effects of high work efficiency, fast heating speed and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

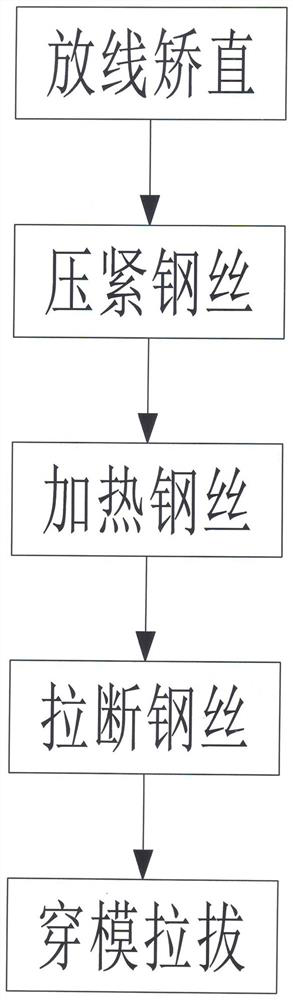

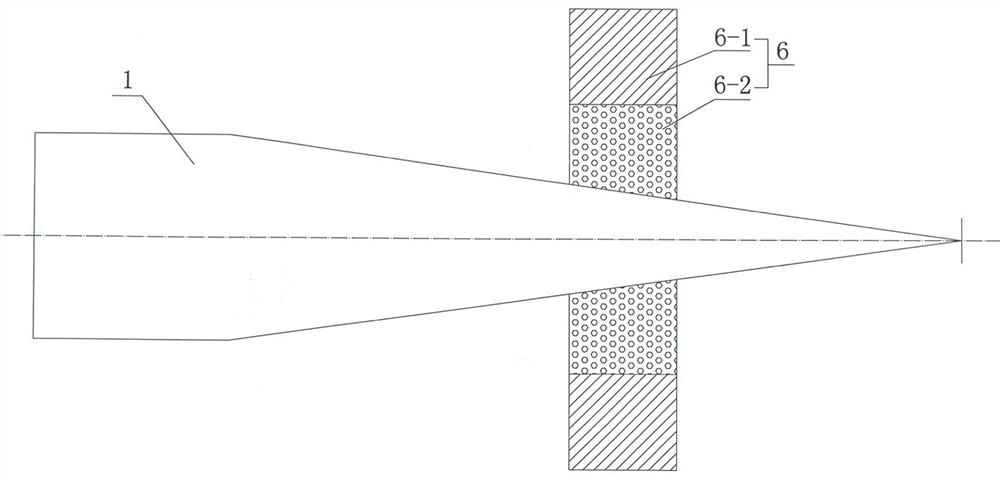

[0025] A kind of sharpening process that is beneficial to steel wire drawing and piercing die in embodiment one is made up of following steps:

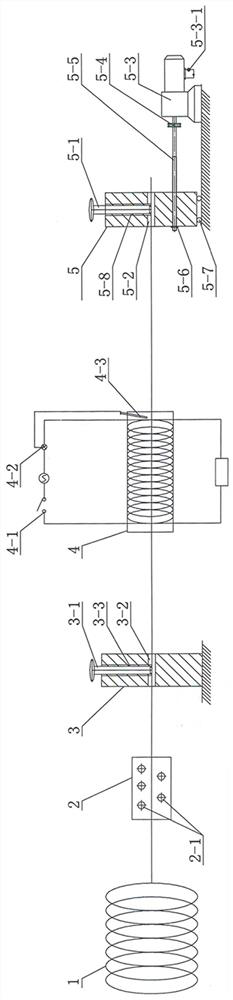

[0026] A. Pay-off and straightening: Unfold a wire rod with a diameter of 15.5mm for pay-off. The unrolled steel wire 1 runs horizontally and horizontally between the upper and lower rows of straightening rollers 2-1 of the rotary straightener 2. During the process, the steel wire 1 is corrected into a straight strip (to facilitate subsequent threading);

[0027] B. Press the steel wire: the straightened steel wire 1 passes through the threading hole Ⅰ3-2 in the fixed chuck 3, the inner cavity of the electromagnetic induction heating tube 4 with a length of 800mm, and the wire hole Ⅱ5 in the moving chuck 5 -2, turn off the rotary straightener 2 at this time; then screw down the pressing bolt Ⅰ3-1 in the fixed chuck 3 and the pressing bolt Ⅱ5-1 in the moving chuck 5 respectively, so that the pressing bolt Ⅰ3- 1 and the lower end of th...

Embodiment 2

[0032] A kind of sharpening process that is beneficial to steel wire drawing and piercing die among the embodiment two is made up of following steps:

[0033] A. Pay-off and straightening: Unfold the wire rod with a diameter of 5.5mm for pay-off, and the unrolled steel wire 1 runs horizontally and horizontally between the upper and lower rows of straightening rollers 2-1 of the rotary straightener 2. During the process, the steel wire 1 is corrected into a straight strip (to facilitate subsequent threading);

[0034] B. Press the steel wire: the straightened steel wire 1 passes through the threading hole Ⅰ3-2 in the fixed chuck 3, the inner cavity of the electromagnetic induction heating tube 4 with a length of 300mm, and the wire hole Ⅱ5 in the moving chuck 5 -2, turn off the rotary straightener 2 at this time; then screw down the pressing bolt Ⅰ3-1 in the fixed chuck 3 and the pressing bolt Ⅱ5-1 in the moving chuck 5 respectively, so that the pressing bolt Ⅰ3- 1 and the low...

Embodiment 3

[0039] A kind of sharpening process that is beneficial to steel wire drawing and piercing die among the embodiment three is made up of following steps:

[0040] A. Pay-off and straightening: Unfold a wire rod with a diameter of 10.5mm for pay-off, and the unrolled steel wire 1 runs horizontally and horizontally between the upper and lower rows of straightening rollers 2-1 of the rotary straightener 2, During the process, the steel wire 1 is corrected into a straight strip (to facilitate subsequent threading);

[0041] B. Press the steel wire: the straightened steel wire 1 passes through the threading hole Ⅰ3-2 in the fixed chuck 3, the inner cavity of the electromagnetic induction heating tube 4 with a length of 600mm, and the wire hole Ⅱ5 in the moving chuck 5 -2, turn off the rotary straightener 2 at this time; then screw down the pressing bolt Ⅰ3-1 in the fixed chuck 3 and the pressing bolt Ⅱ5-1 in the moving chuck 5 respectively, so that the pressing bolt Ⅰ3- 1 and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com