One-time forming device and method for longitudinal submerged arc welding steel pipe

A technology of straight seam submerged arc and forming device, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of large deviation between the outer diameter of the steel pipe end and the outer diameter of the pipe, the production speed is not related to each other, and the limitation of raw material selection is small. and other problems, to achieve the effect of improving production safety factor, stable molding quality, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the examples and drawings. The scope of the present invention is not limited to the embodiment, and any change in the scope of the invention is also a range of protection according to the scope of the invention.

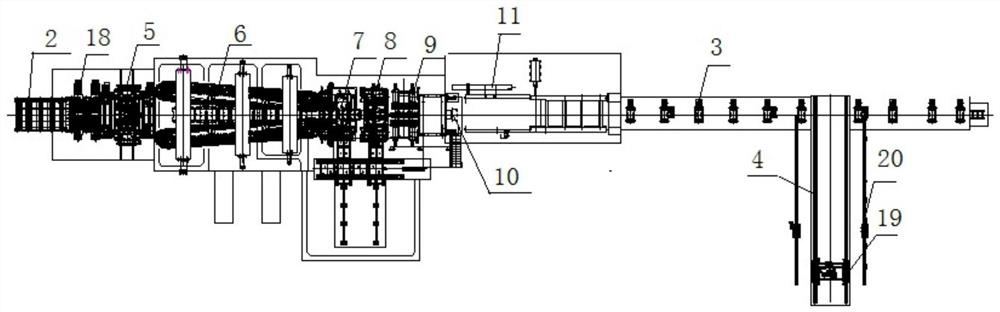

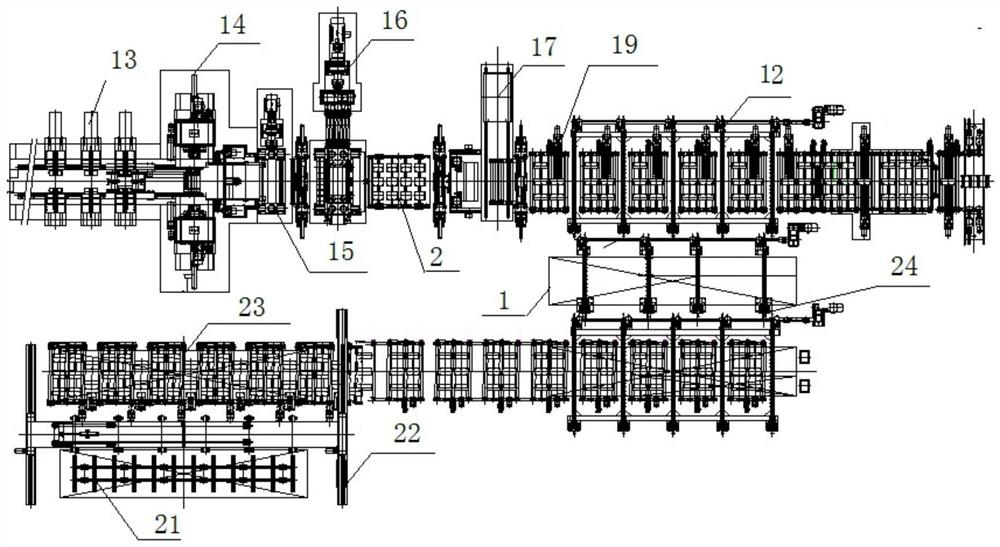

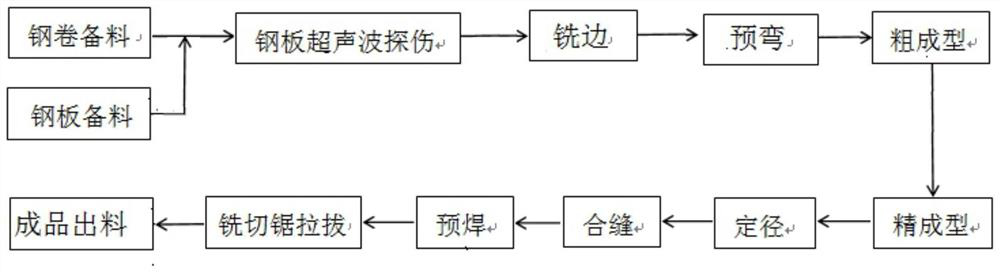

[0017] The first-selection of the decad arc welded steel pipe of the present invention is like figure 1 As shown, a backup device, a material delivery roller, a milling machine, and a primary molding. The primary molding combination machine includes a pre-bending machine 5, a crude molding machine 6, a molding machine 7, a fixing plane 8, a selection machine 9, a prepaner 10, and a milling sawing device 11. The backup device is sequentially and milling machine, pre-bending machine, crude molding machine, fine molding machine, fixed-to-plane, sewing machine, pre-welder and milling, and milling, preparation equipment. A steel plate ultrasonic measuring instrument is provided between the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com