High-performance composite board cutting machine and efficient cutting method

A composite board and cutting machine technology, applied in metal processing and other directions, can solve the problems that affect the splicing accuracy of the cutting surface of the knife edge and the cutting surface of the knife edge, cannot cut the vertical cutting surface of the knife edge surface, and cannot form vertical downward pressure, etc., to achieve manual cutting resistance The effect of small size, lower movement resistance and lower labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

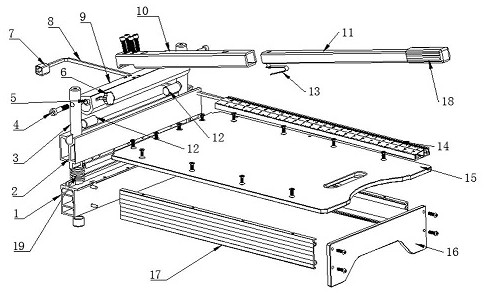

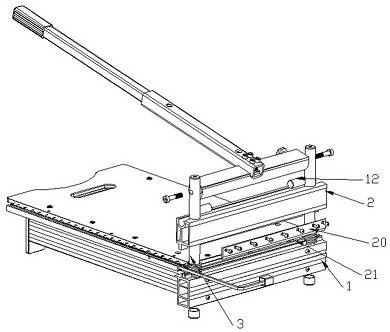

[0012] Embodiment 1: with reference to accompanying drawing and 2. A high-performance composite board cutting machine, two guide posts 3 in the composite board cutting machine are respectively fixed on the two ends of the guide post fixing seat 1, and the two ends of the blade fixing seat 2 are provided with guide post through holes and are passed through 19 sets of springs. On the guide post 3, there are concentric circular arc grooves on the upper end surface of the blade holder 2, and the vertical centerline of the concentric circular arc grooves is not on the same line as the vertical centerline of the guide post. The roller 12 and the eccentric drive tube 9 are located on the drag-reducing roller 12 and the two ends of the eccentric drive tube 9 are connected eccentrically with the guide post 3 respectively, the blade 20 is connected to the lower end surface of the blade holder 2 and the vertical line of the blade 20 is connected to the blade holder 2 The center lines in ...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, a high-efficiency cutting method of a high-performance composite board cutting machine. When cutting a composite board, the composite board is placed under the edge of the blade 20, and the pressing rod exerts pressure downward to drive the eccentric drive. When the tube 9 rotates, the circular face of the eccentric drive tube 9 forms a relative rolling downward pressure on the drag-reducing roller 12 located in the concentric circular arc groove on the upper end surface of the fixed seat 2, and the drag-reducing roller 12 presses down on the blade during rolling The fixed seat 2 forms a rolling downward pressure, thereby forcing the blade 20 fixed below the blade fixed seat 2 to cut the composite wood board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com