Device for pipe annealing and using method

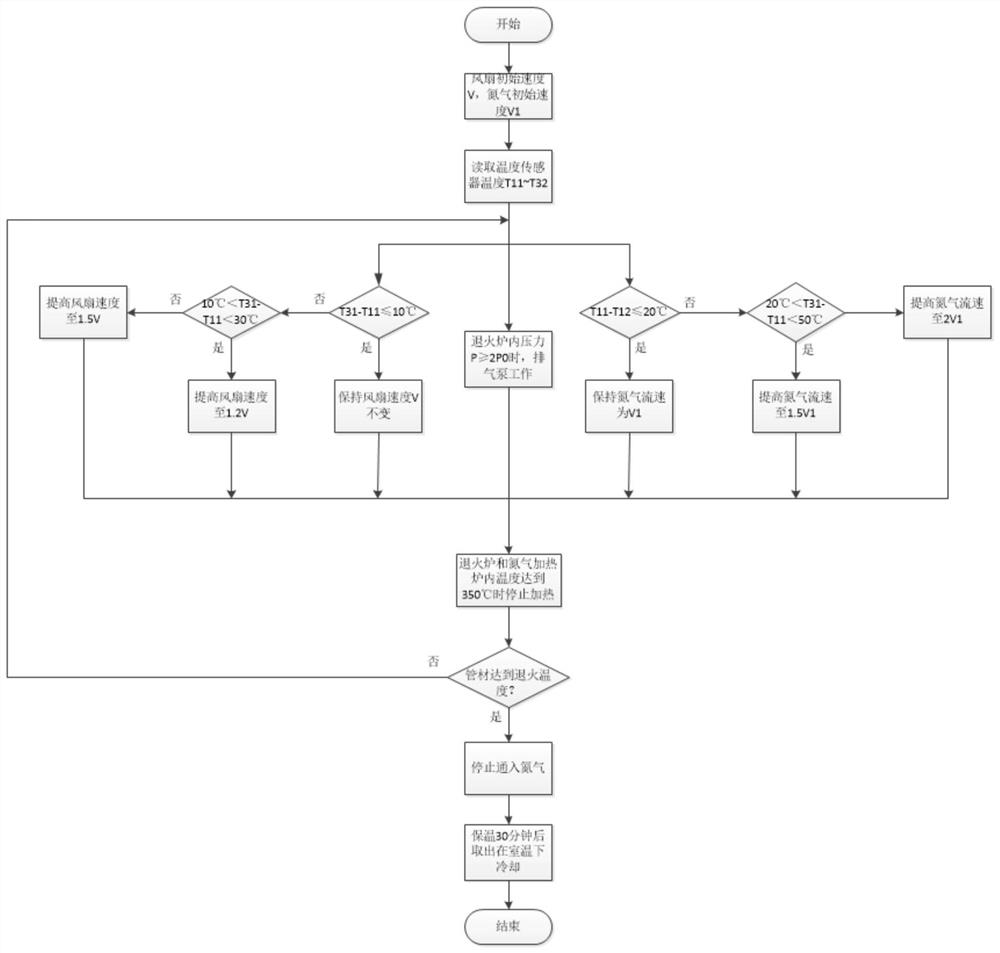

A pipe and annealing technology, which is applied in the field of heat treatment, can solve the problems of not being able to ensure uniform heating of the pipe, and the inability to control the annealing temperature of the pipe, so as to achieve the effects of excellent mechanical properties, eliminating residual stress, and avoiding excessively high or low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

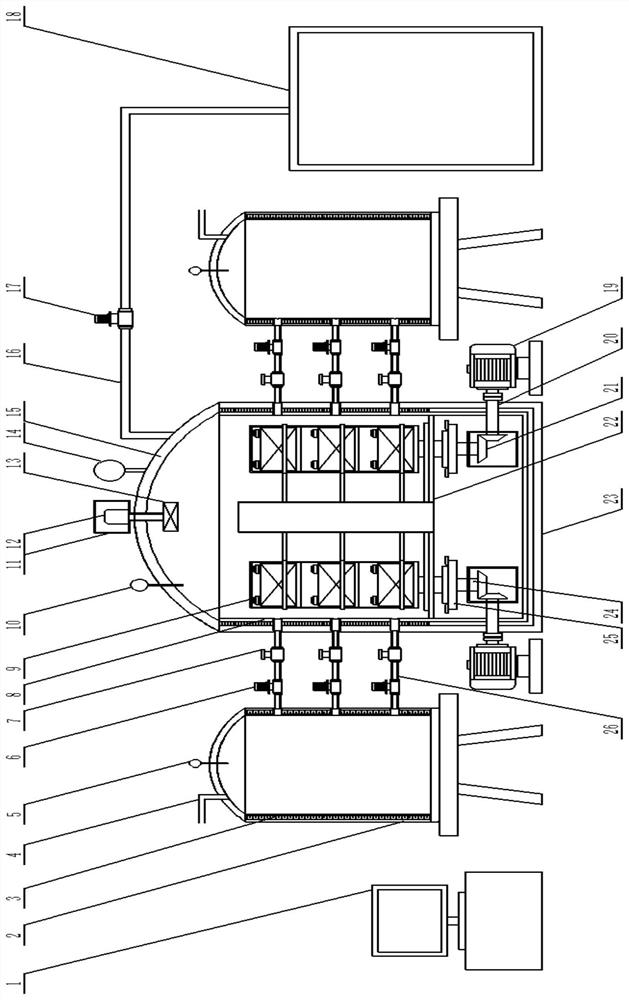

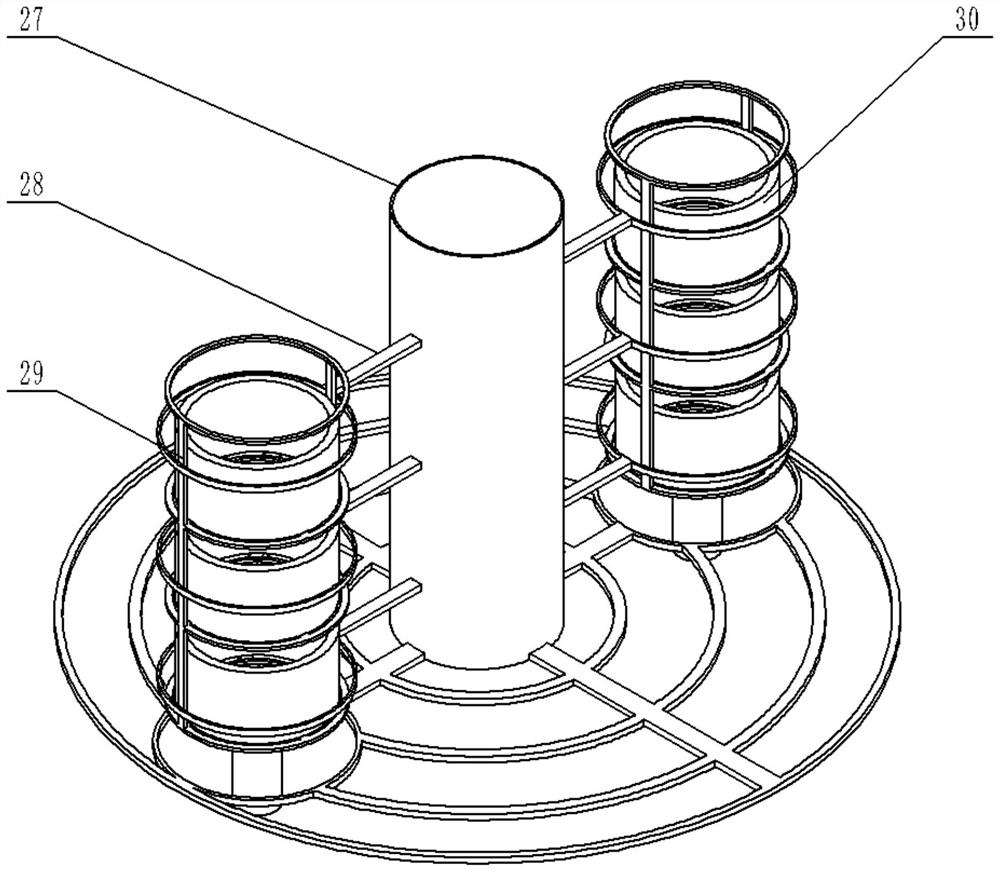

[0043] Apparatus and methods for annealing pipes, such as figure 1 As shown, it includes a computer 1 , a nitrogen heating furnace assembly, an annealing furnace assembly, a fixed guide assembly and a pipe 30 .

[0044] A nitrogen heating furnace assembly, which includes a nitrogen heating furnace 2, a resistance wire 3, a nitrogen delivery pipe 4, a first temperature measuring probe 5, an air pump 6, an automatic flow control valve 7, an exhaust pipe 16, an exhaust pump 17, and a nitrogen collection chamber 18 And air pipe 26.

[0045] The inner surface of the nitrogen heating furnace 2 is provided with a resistance wire 3, the nitrogen delivery pipe 4 is located on one side of the top of the nitrogen heating furnace 2, the first temperature measuring probe 5 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com