Volume control type valve

A technology of volume control and valve control, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of expensive upstream controllers, difficult processing, low efficiency, etc., and achieve small leakage and low overall cost , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

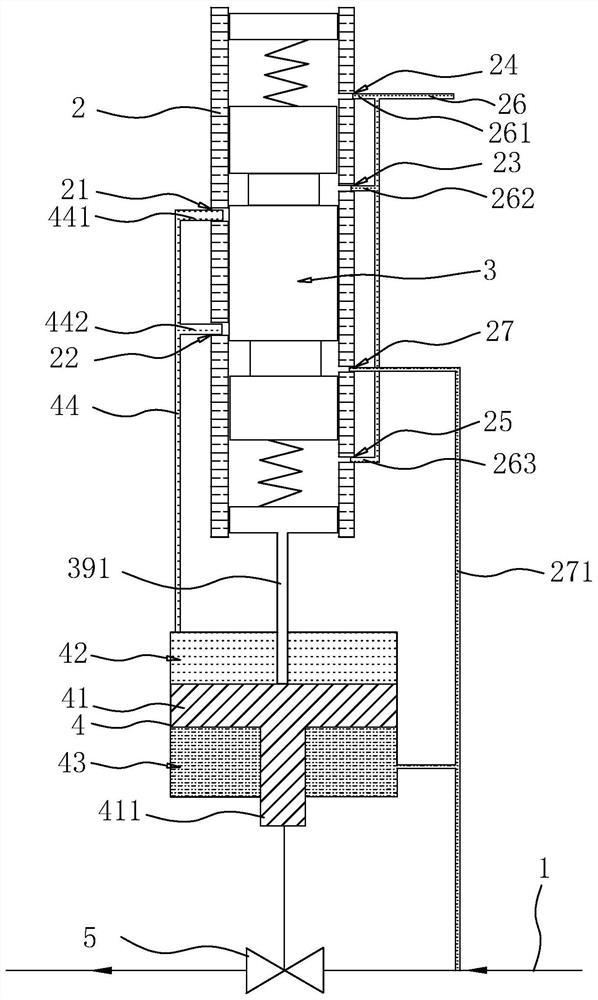

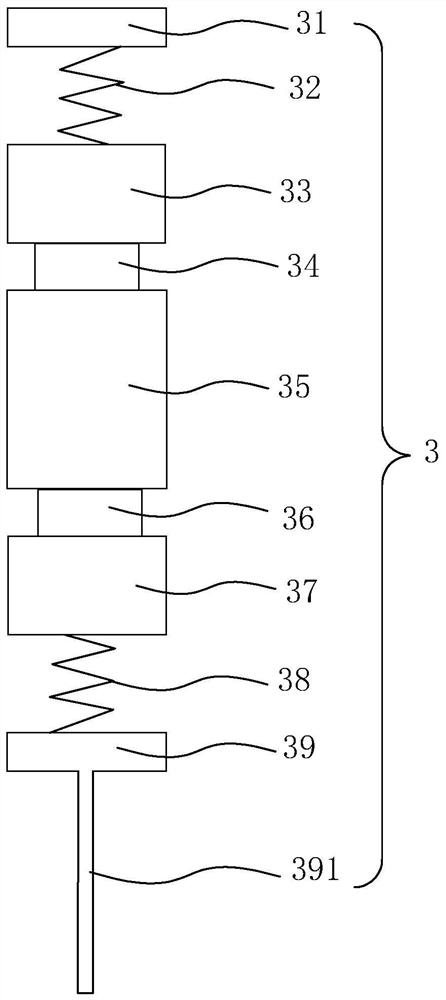

[0041] Embodiment 1 of the present application discloses a volume control valve. see figure 1 , a volume control valve includes a controlled valve 5 fixed on a pipeline 1, an oil storage tank 4 is connected to the controlled valve 5, a control valve body 2 is connected to the oil storage tank 4, and the control valve body 2 is hollow Setting, the control valve body 2 is provided with a control valve spool 3; an input signal is sent to the control valve spool 3, and the input signal can be an electric control signal, such as a pneumatic control signal, a hydraulic control signal, and a solenoid valve control signal, etc., to control The valve core 3 moves in the control valve body 2 to change the volume of oil in the control oil storage tank 4, thereby controlling the opening and closing of the controlled valve 5.

[0042] An output piston 41 is slidably connected in the oil storage tank 4. The output piston 41 divides the oil storage tank 4 into a control oil chamber 42 and a...

Embodiment 2

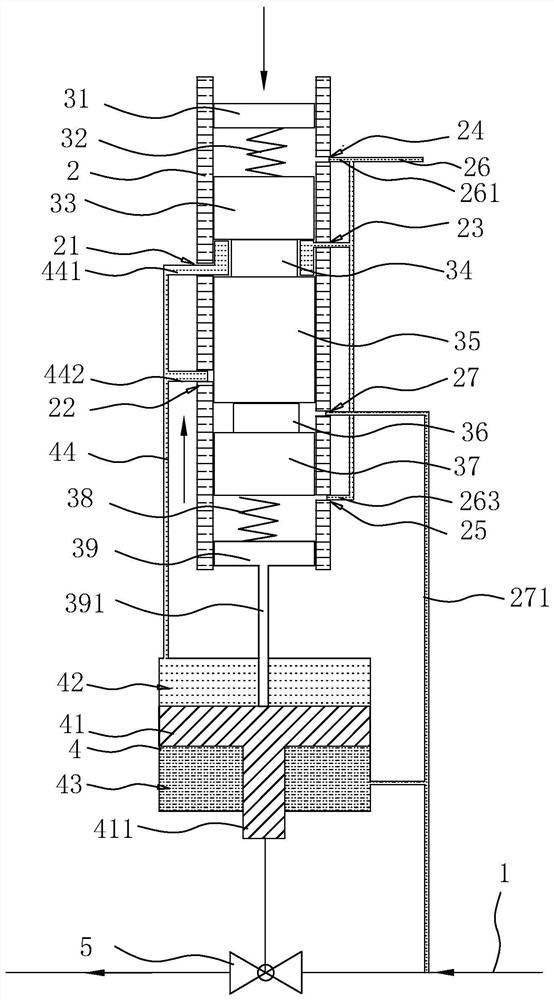

[0054]Embodiment 2 of the present application discloses a volume control valve, which differs from Embodiment 1 in that, see figure 1 , change the input signal into a displacement signal, and the feedback becomes the control valve body 2, that is, the bottom of the control valve body 2 is closed, and the spool does not have a receiving column 31 and an input spring 32, and the input signal is directly transmitted to the connecting column 1 33, and the feedback One end of the spring 38 away from the connecting column 2 37 is directly fixed on the bottom of the control valve body 2; The two branch pipes 442 communicate with the oil inlet pipe 271 and connect the original oil inlet 27 with the remaining oil pipe 26 .

[0055] The working principle of a volume control valve in Embodiment 2 of the present application is: the displacement signal moves upward, driving the control valve spool 3 to move upward, so that the second oil guide port 22 and the second oil inlet port 27 are c...

Embodiment 3

[0058] Embodiment 3 of the present application discloses a volume control valve, see Figure 8 , which is different from Embodiment 1 in that the pipeline 1 is fixed with a differential pressure valve 6, and the differential pressure valve 6 does not require external energy, and the proportional flow control valve is more efficient than the traditional proportional flow control valve due to the inclusion of self-feedback. The control accuracy is higher, but the overall cost is lower. The differential pressure valve 6 does not require external energy, and relies on the pressure change of the regulated medium to automatically adjust, automatically eliminates the remaining pressure head of the pipe network and the flow change caused by pressure fluctuations, and keeps the pressure difference between the inlet and outlet of the pipeline 1, which helps to stabilize the operation of the system , can achieve high-precision proportional flow control.

[0059] The working principle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com