Flexible wearable pressure sensor with ultrahigh capacitance and pressure sensor array

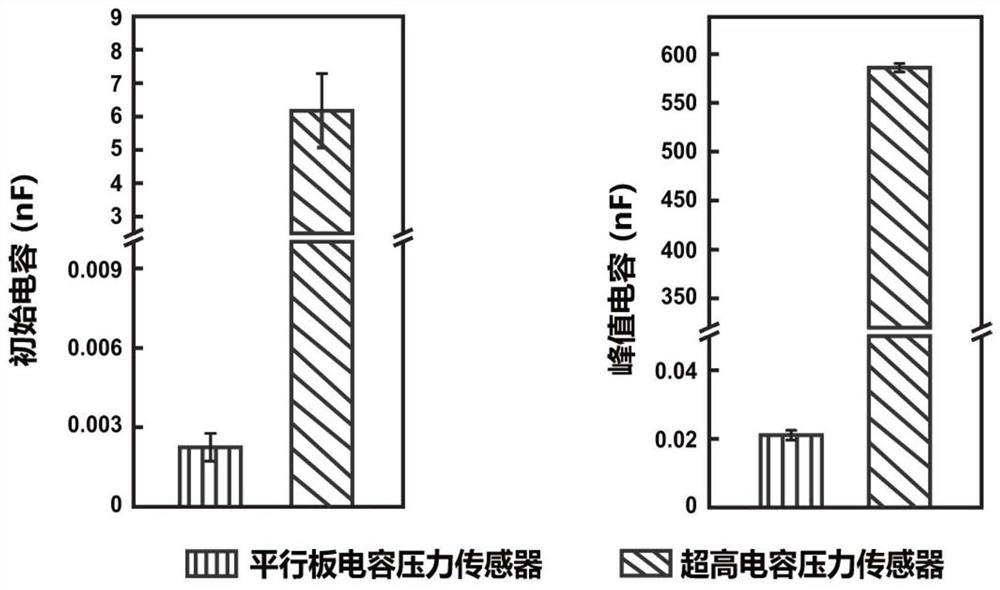

A pressure sensor, ultra-high capacitance technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of unfavorable application, susceptibility to noise interference sensitivity, etc., and achieve high signal-to-noise ratio, high sensitivity, and good pressure sensing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

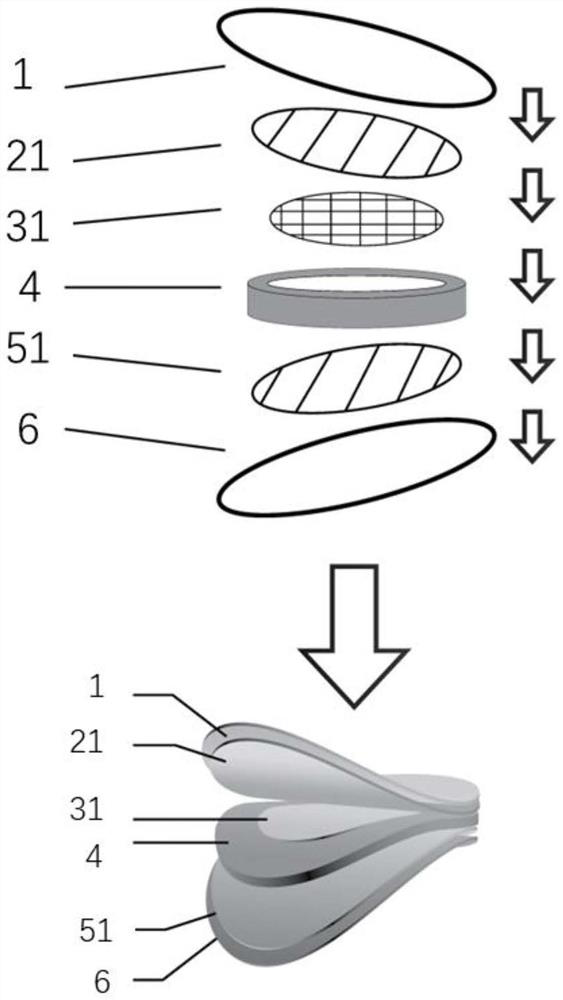

[0037] like figure 1 As shown, a flexible wearable pressure sensor with ultra-high capacitance includes an upper encapsulation layer 1, an upper conductive fabric electrode 21, a middle support frame 4, a lower conductive fabric electrode 51 and a lower encapsulation layer arranged sequentially from top to bottom. Layer 6, the central conductive hydrogel 31 is arranged in the central support frame 4 .

[0038] Wherein, the conductive hydrogel used is cylindrical, with a thickness of 4 mm and a radius of 3 mm. The preparation method of the conductive hydrogel is as follows: dissolving acrylamide monomer (9.98wt%) and sodium chloride or lithium chloride (16.16wt%) in deionized water to prepare an acrylamide-salt ion solution. A solution of N,N-methylenebisacrylamide was prepared as a crosslinking agent, and its solution concentration was 1.2wt%. Next, mix and stir the crosslinking agent solution (1.13wt%), ketoglutaric acid (photoinitiator) (2.2wt%), acrylamide-salt ion soluti...

Embodiment 2

[0045] like Figure 4 As shown, this embodiment provides a flexible and wearable two-dimensional pressure sensing array with ultra-high capacitance, which includes 16 sensing units, and each sensing unit is arranged in the same plane in an orthogonal arrangement. The specific structure is that the upper encapsulation layer 1, the upper conductive fabric electrode layer 2, the middle conductive hydrogel layer 3, the lower conductive fabric electrode layer 5 and the lower encapsulation layer 6 are sequentially arranged from top to bottom;

[0046] The upper conductive woven electrode layer 2 includes four upper conductive woven electrodes 21 arranged at equal intervals, the lower conductive woven electrode layer 5 includes four lower conductive woven electrodes 51 arranged at equal intervals, the four upper conductive woven electrodes 21 and The four lower conductive fabric electrodes 51 are arranged in a vertically intersecting manner;

[0047] The middle conductive hydrogel l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com