A pressure transmitter with overpressure protection

A transmitter and pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of poor overpressure protection effect and achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

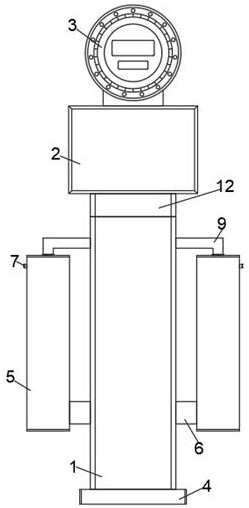

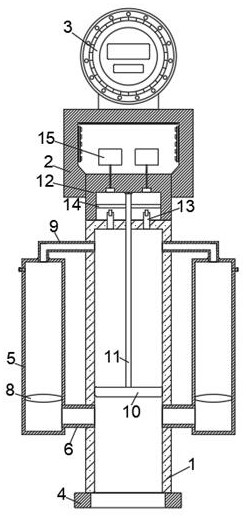

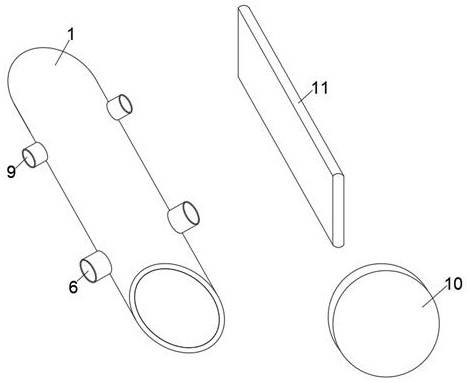

[0051] See Figure 1-3 As shown, a pressure transmitter having overpressive protection, including the inverting chamber 1, the conversion chamber 2, and the display 3, and the pressure input port 4 is provided at the bottom of the press cavity 1, and the inner diameter of the pressure input port 4 is larger than the induced cavity. The inner diameter of 1, the pressure fluid enters the inside of the pressing chamber 1 through the pressure input port 4, and both sides of the press cavity 1 are provided with the buffer chamber 5, the buffer cavity 5 is close to one end of the pressure input port 4 and the inside of the inverting chamber 1. The wall is fixedly connected to the input conduit 6, and the input conduit 6 is provided with an electromagnetic valve, and the solenoid valve of the input conduit 6 is used to truncate the input pipe 6 in the case of overpressure and the pressure relief, and the fluid is further entered by input pipe 6. When the buffer cavity 5 is inside, while t...

Embodiment 2

[0057] Please participate figure 2 As shown, the front surface of the display 3 is provided with a processor, and the processor communication is connected to an overpressure analysis module, the monitoring module, the storage module, and the controller are used to control the solenoid valve of the input conduit 6 and the solenoid valve of the pressure relief conduit 7. The opening and closing, switching the pressure and detection mode by inputting the pipe 6 and the solenoid valve of the pressure relief pipe 7, the overpressure analysis module is used to perform pressure overload analysis of the two buffer cavities 5, and the operation monitoring module is used to devices. The operation status is detected, and the storage module is used to store the running data of the device;

[0058] The process of pressure overload analysis of the overpressure analysis module to the buffer cavity 5 includes the following steps:

[0059] Step S1: After inputting the pressure fluid over the press...

Embodiment 3

[0071] See Figure 5 As shown in, for example, in Example 1 of the present embodiment is distinguished in that the side surface of the baffle 10 into the pressure chamber and the active side wall 1 is connected, and an electromagnetic snap between an inner sidewall of the baffle 10 into the top edge of the pressure chamber , the inner surface of the top wall 11 and the isolation diaphragm chamber 12 is fixedly connected to the bottom surface of the spacer 11 defines a slot 16, the top wall 16 is fixed into the slot with a spring 17 mounted evenly distributed, uniform distribution of the bottom of the spring 17 of the fixedly mounted between the pressure relief block 18, block 18 extends to the bottom of the relief slot 16 and the outer surface of the embedded baffle 10 mounted on the top of the pressure relief block 18 are connected to the front and rear sides of the inner sidewall into the pressure chamber 1 activity is provided with a gasket 18 between the block surface and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com