Industrial controller for intelligent manufacturing

An industrial controller, intelligent manufacturing technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problems of unable to realize intelligent manufacturing and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

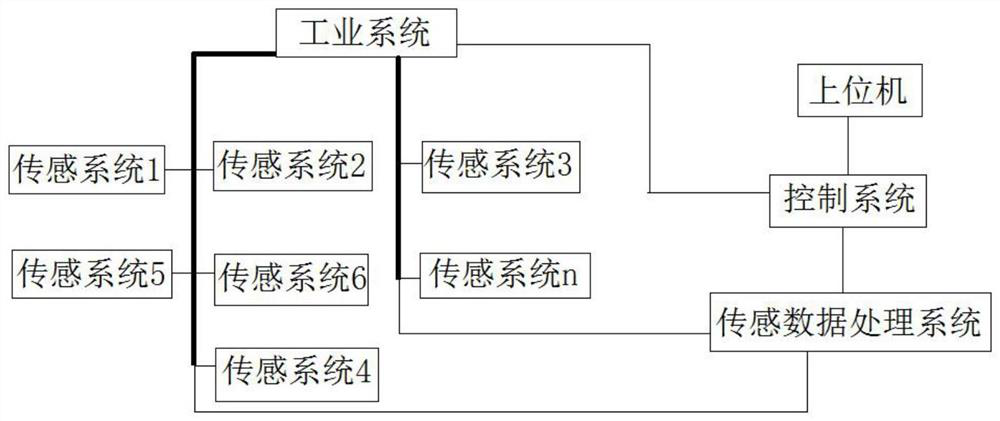

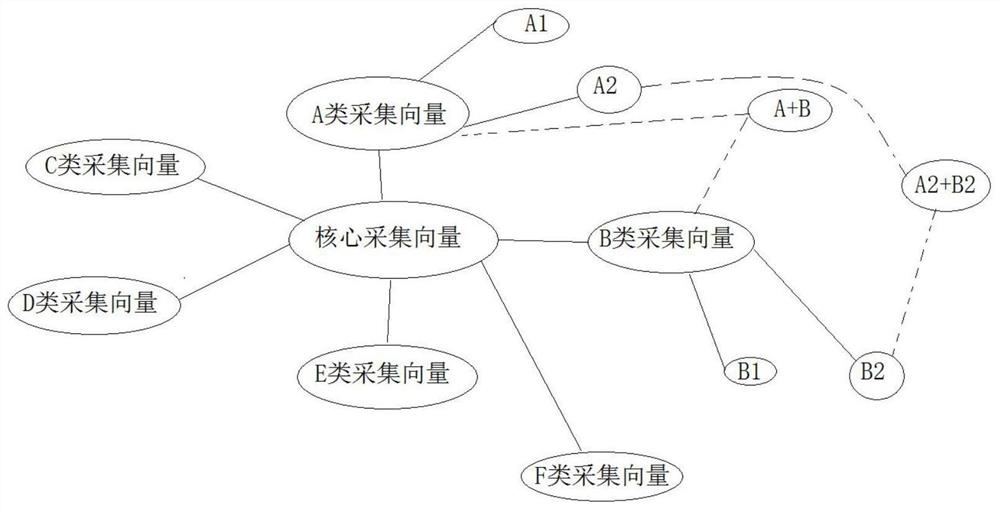

[0021] In specific implementation, such as figure 1 The illustrated embodiment of the industrial controller for intelligent manufacturing of the present application includes several sensing systems (1-n), a sensing data processing system and a control system, and the several sensing systems (1-n) Each of the sensing systems is connected to the industrial system and specifically one or more corresponding sensors are set in the industrial system, each of the several sensing systems (1-n) is connected to the sensing system The data processing system is electrically connected, and each of the plurality of sensing systems (1-n) transmits sensing signals to the sensing data processing system, and the sensing data processing system is used to convert the sensing The sensing signal is processed into specific acquisition vector data according to the sensing type, the sensing data processing system is electrically connected with the control system, and the sensing data processing system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com