Efficient waste tire pyrolysis waste gas collecting device and collecting method thereof

A waste gas collection and waste tire technology, which is applied in the field of efficient waste tire pyrolysis waste gas collection device, can solve the problems that affect the health of the staff, leakage, and difficulty in direct treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

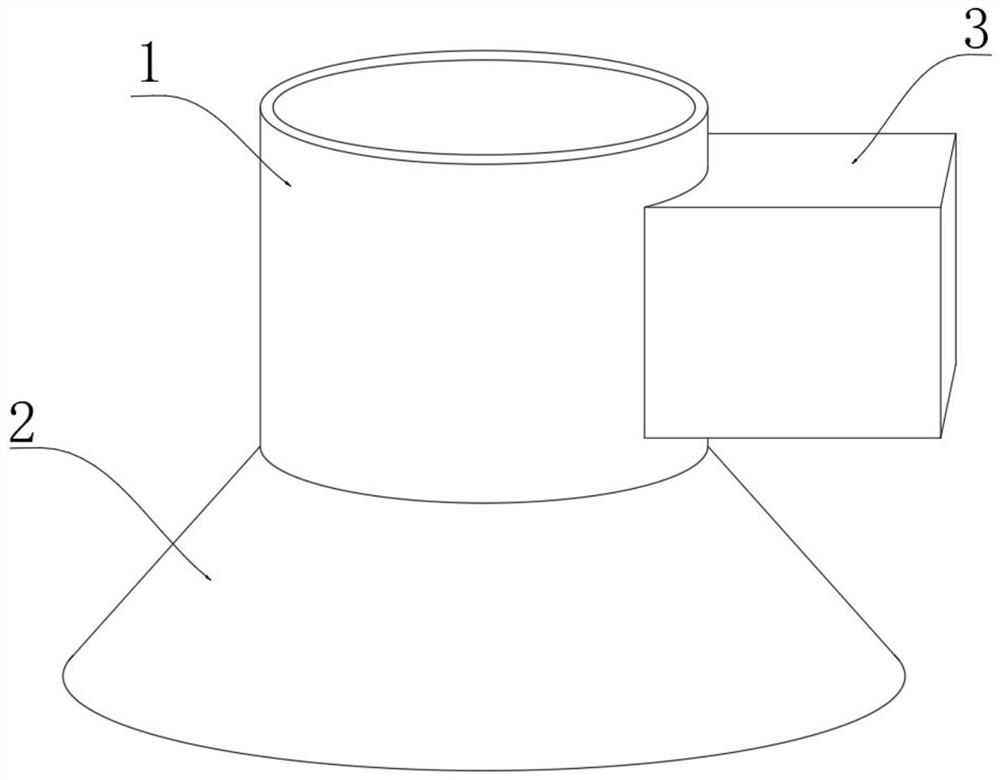

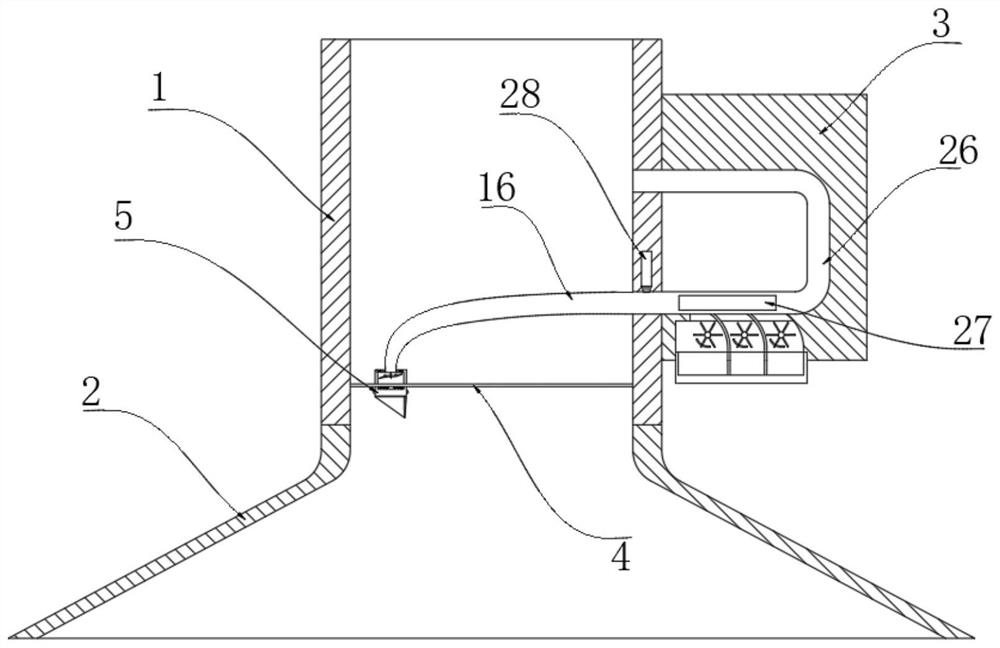

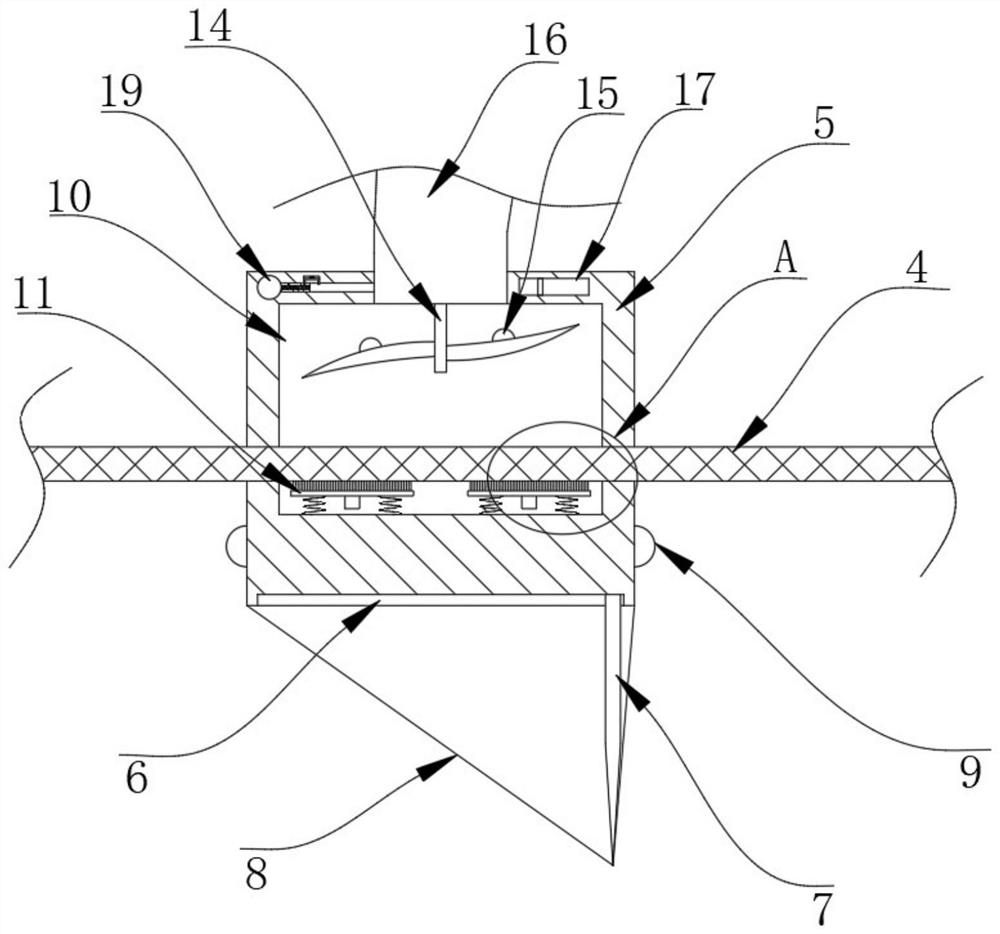

[0038] refer to Figure 1-8 , a high-efficiency pyrolysis waste gas collection device for waste tires, including an air collection pipe 1, an air collection hood 2 and an external air extraction system. The air extraction system works to pump the waste gas pyrolyzed from waste tires into the air collection pipe 1 through the air collection hood 2 , the gas collecting hood is fixed on the bottom of the gas collecting pipe 1, a filter screen 4 is fixedly connected inside the gas collecting pipe 1, and a collecting box 3 is fixedly connected to the inner wall of the gas collecting pipe 1;

[0039] A movable block 5 is slidably connected to the filter screen 4, and the movable block 5 can slide left and right on the filter screen 4, thereby cleaning the filter screen 4 and avoiding blockage caused by too much local impurities. There is a slider 7 slidingly connected in the slot 6 and the chute 6, the slider 7 is a long strip structure, the bottom of the movable block 5 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com