Method for reconstructing machined surface texture through laser shock peening path

A technology of laser shock strengthening and surface processing, which is applied in the field of surface texture processing of parts, can solve the problems of lack, underestimation of the application possibility of laser shock strengthening, lack of pertinence, etc., and achieve the effect of improving the ability of initiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

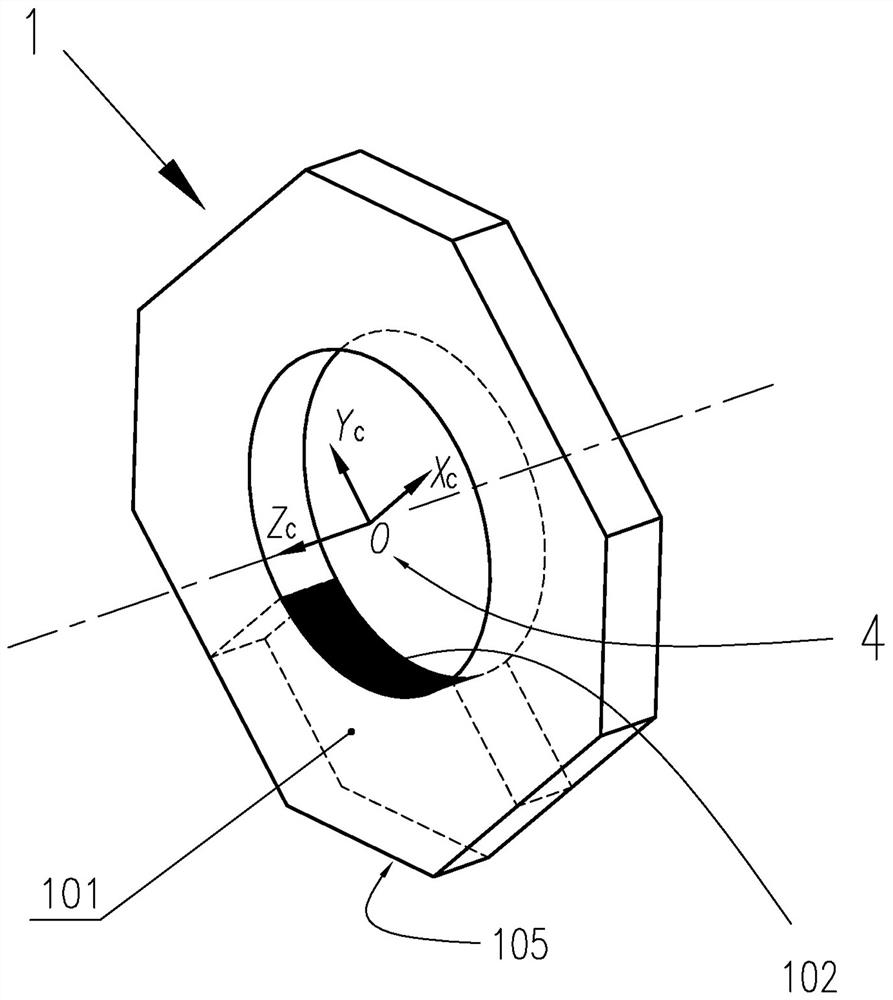

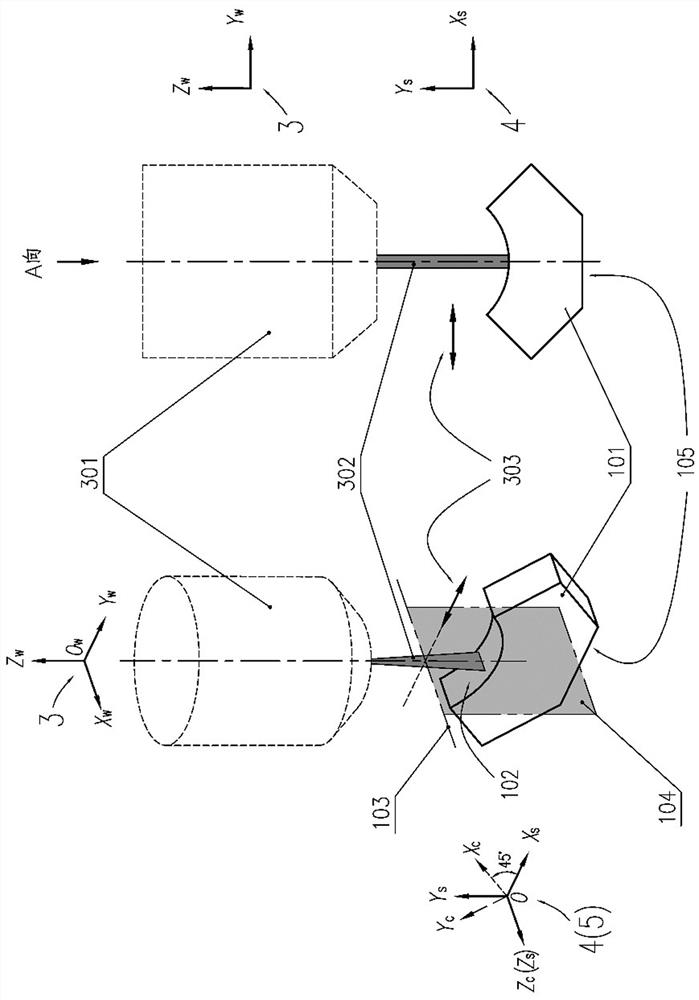

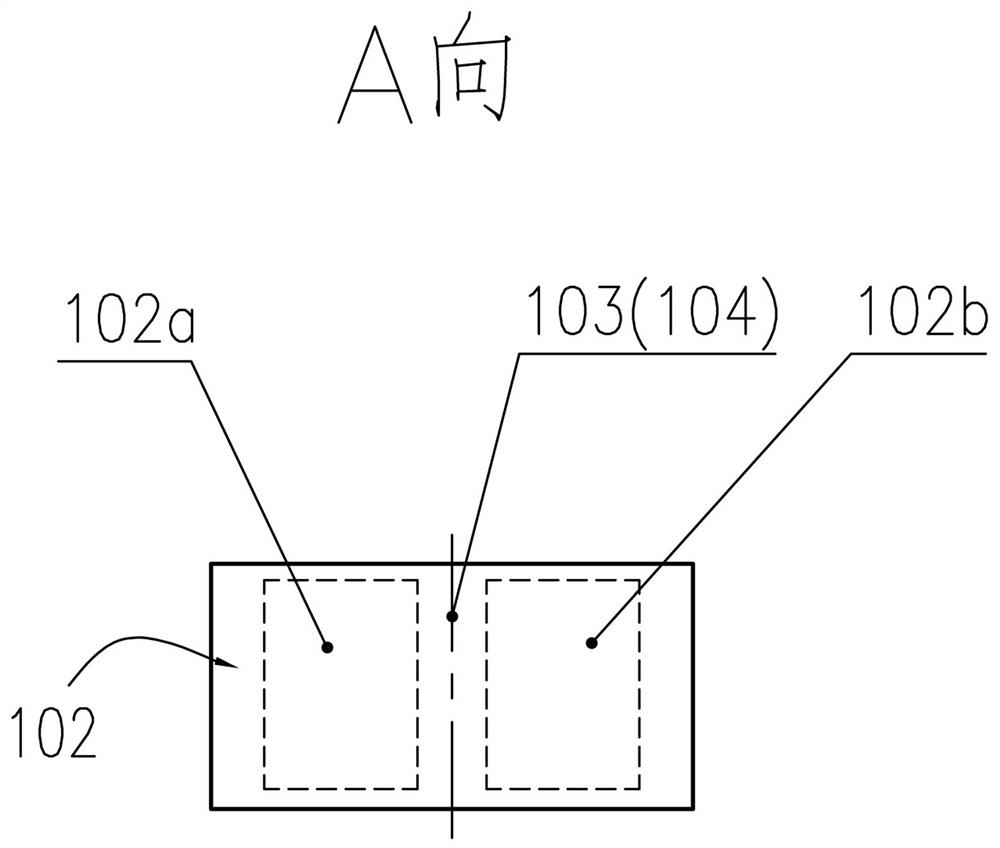

[0070] The hole diameter is Taking specimen 1 as an example, four sets of machined inner hole surfaces 102 are obtained through four sets of different milling parameters, and the set numbers are MG1, MG2, MG3 and MG4. Using the method proposed by the present invention, the optimal overlapping ratios of the light spot 202 in the circumferential direction and axial direction are calculated to be 45% and 40% respectively through formulas (1) to (4). On this basis, two different laser shock strengthening paths 203a and 203b are set (attached Figure 4 ), strengthen the inner hole surface 102 respectively, and obtain the strengthened surface 204. Compare the surface skewness and kurtosis values of each group of specimens 1 before and after strengthening (attached Figure 6 ), and fretting fatigue life (attached Figure 7 ). It can be seen from the results that the surface texture of the machined surface is reconstructed through the laser shock strengthening route, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com