Tool turret and rotating power head thereof

A technology of rotating power head and turret, applied in driving devices, manufacturing tools, metal processing mechanical parts, etc., can solve problems such as inconvenience, and achieve the effect of reducing torque and simplifying transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

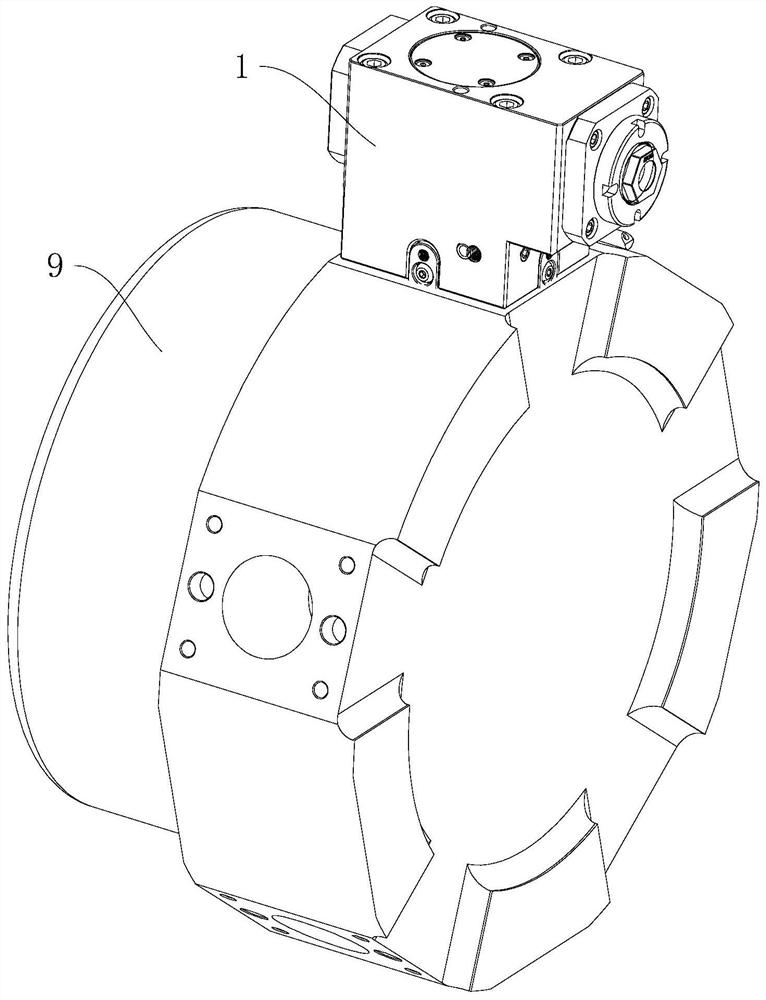

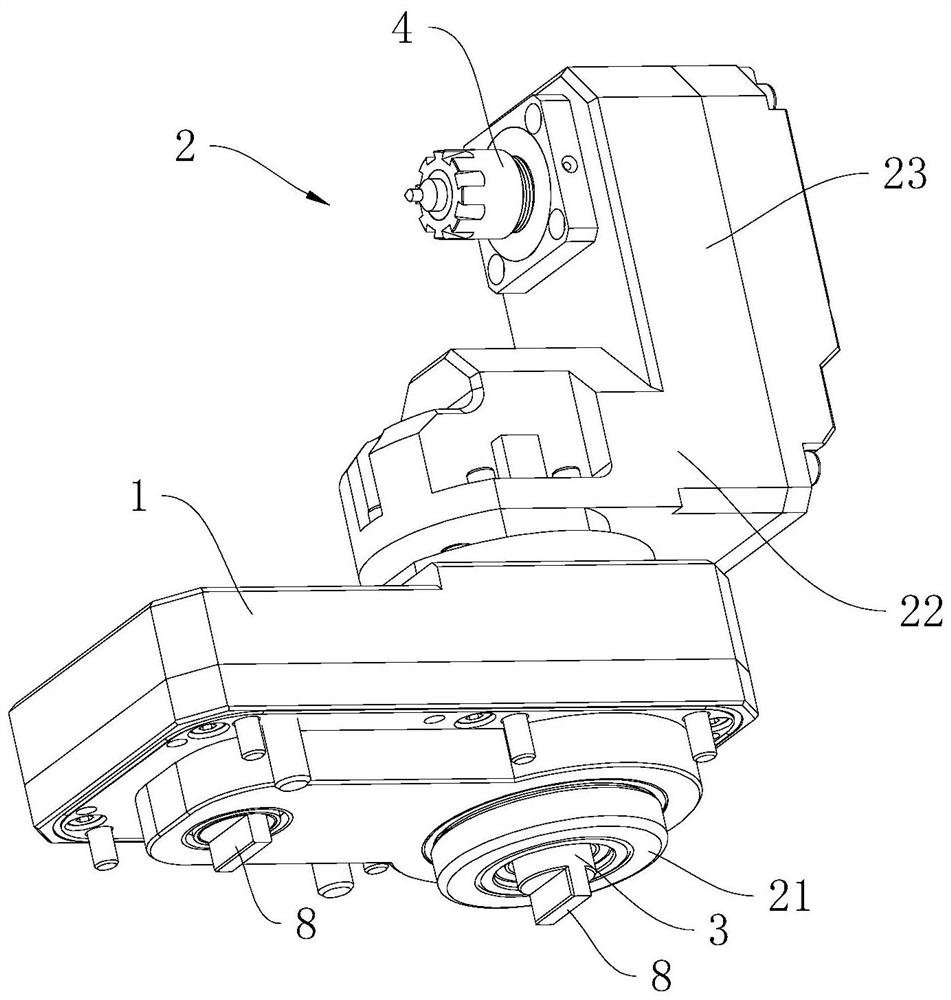

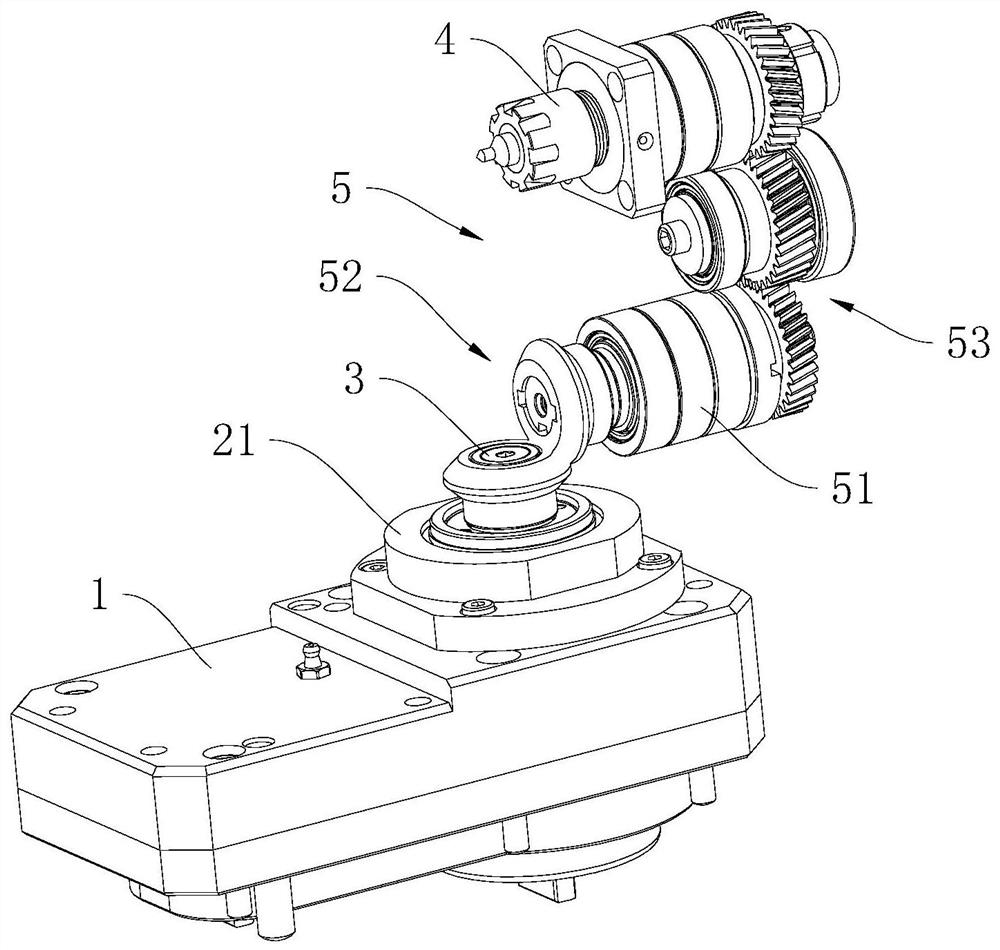

[0047] refer to figure 2 , 3 , a rotary power head, including a tool holder 1, a tool holder 2, a drive input shaft 3, a drive output shaft 4 and a drive transmission assembly 5. The knife holder 1 is fixedly connected to the cutter head 9 , the knife holder 2 is arranged on the knife holder 1 , and the drive input shaft 3 , the drive output shaft 4 and the drive transmission assembly 5 are all connected to the knife holder 2 .

[0048] The knife holder 2 includes a cylinder body 21 , a connecting portion 22 and a mounting portion 23 . The cylinder body 21 is embedded into the knife seat 1 , and at least one end of the cylinder body 21 extends out of the knife seat 1 . In this embodiment, both axial ends of the barrel 21 protrude from the tool holder 1 .

[0049] The drive input shaft 3 is coaxially rotatably connected in the cylinder body 21 through bearings, and both ends of the drive input shaft 3 extend out of the cylinder body 21 . The connecting portion 22 is fixedl...

Embodiment 2

[0059] refer to Figure 5 , 6 , the difference between this embodiment and embodiment 1 is that

[0060] The installation portion 23 includes a main body 231 and an end cover 232 ; and the end cover 232 defines an installation hole 233 for installing the drive output shaft 4 .

[0061] The drive output shaft 4 includes a coaxial shaft body 31 and a retaining ring 32 . One end of the shaft body 31 passes through the installation hole 233 and extends into the main body 231, and is connected to the main body 231 through bearing rotation; and one end of the shaft body 31 extending into the installation part 23 is connected to the drive transmission assembly 5; the other end of the shaft body 31 extends out The mounting part 23 is used for connecting the tool. The retaining ring 32 is disposed on the outer periphery of the shaft body 31 , and the end surface of the retaining ring 32 is slidably attached to the surface of the end cover 232 facing away from the main body 231 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com