Preparation method of efficient explosive composite pipe rod based on water pressure

A composite rod and composite pipe technology, which is applied in the field of explosive welding, can solve the problems such as the inability to adjust the size of the pipe and rod to be composited in time according to the actual situation, the low utilization rate of explosive energy, and the ablation damage of composite materials, so as to avoid surface burning. Corrosion, reduce dust and noise pollution, high energy utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Provided in conjunction with the accompanying drawings, a method for preparing a low-energy and high-efficiency explosive composite pipe includes the following steps:

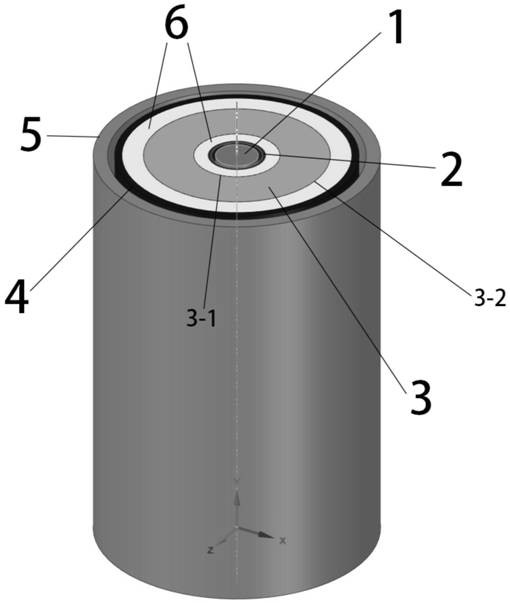

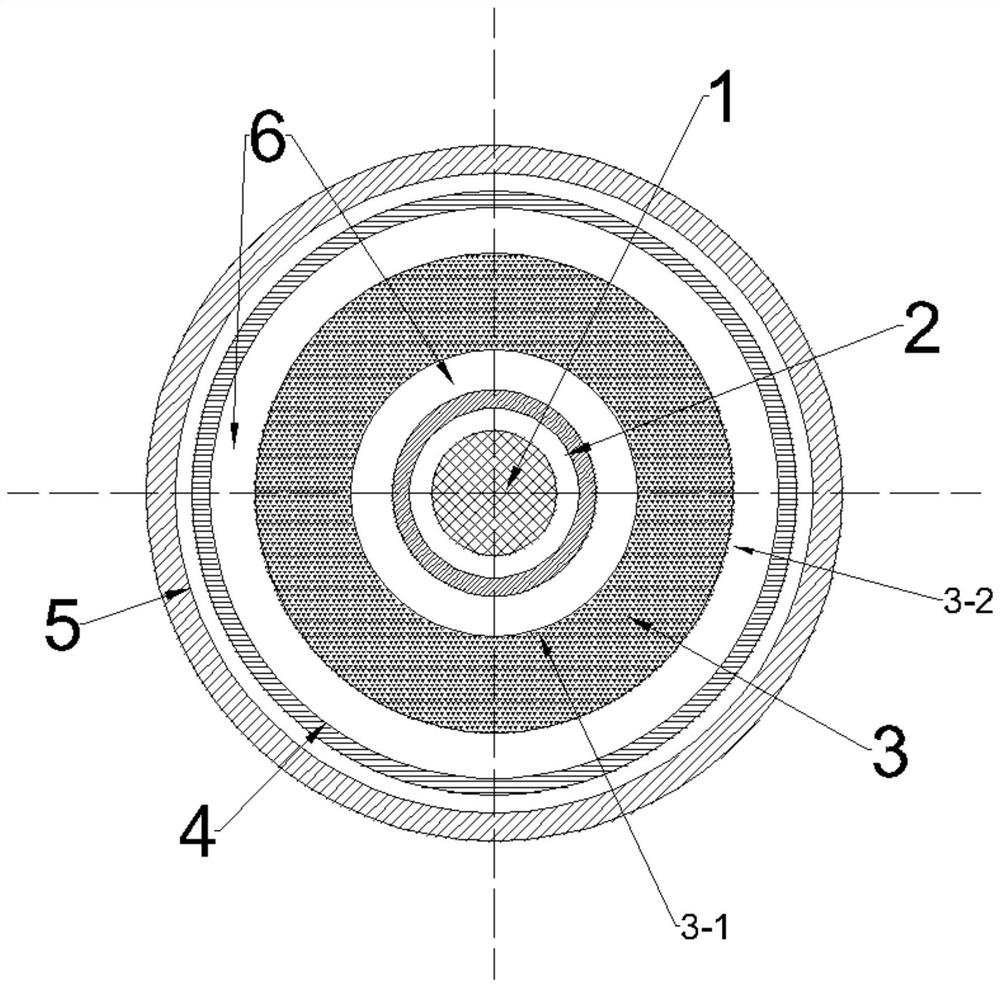

[0015] 1) From the inside to the outside, the bar to be compounded 1, the pipe to be compounded 2, the small-radius PVC pipe 3-1, the large-radius PVC pipe 3-2, the pipe to be compounded 4, and the pipe to be compounded 5 are coaxially arranged in sequence;

[0016] 2) Filling detonators and explosives between the small-radius pcv pipe 3-1 and the large-radius pvc pipe 3-2 to make an explosive device 3; filling water between the pipe to be composited 2, the explosive device, and the pipe to be composited 4, and constructing An incompressible water environment6;

[0017] 3) Detonating the explosive device, using water pressure to transmit the high pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com