Method for preparing single-walled carbon nanotubes with graphene as catalyst

A single-walled carbon nanotube and graphene technology, applied in carbon nanotubes, graphene, chemical instruments and methods, etc., can solve problems affecting device performance, metal residues, etc., and achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

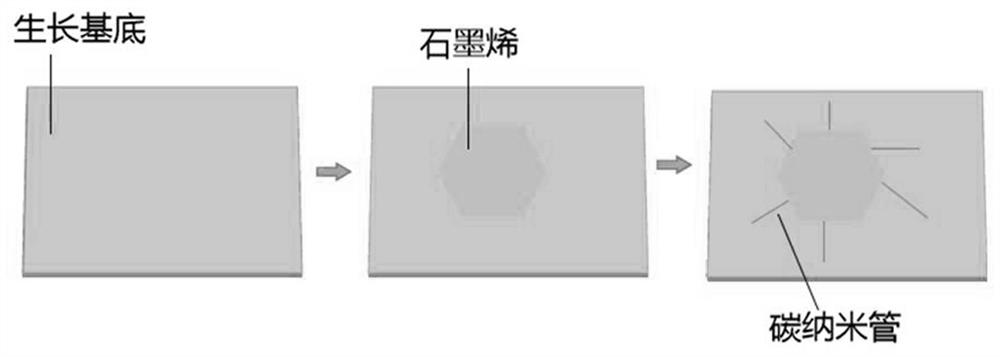

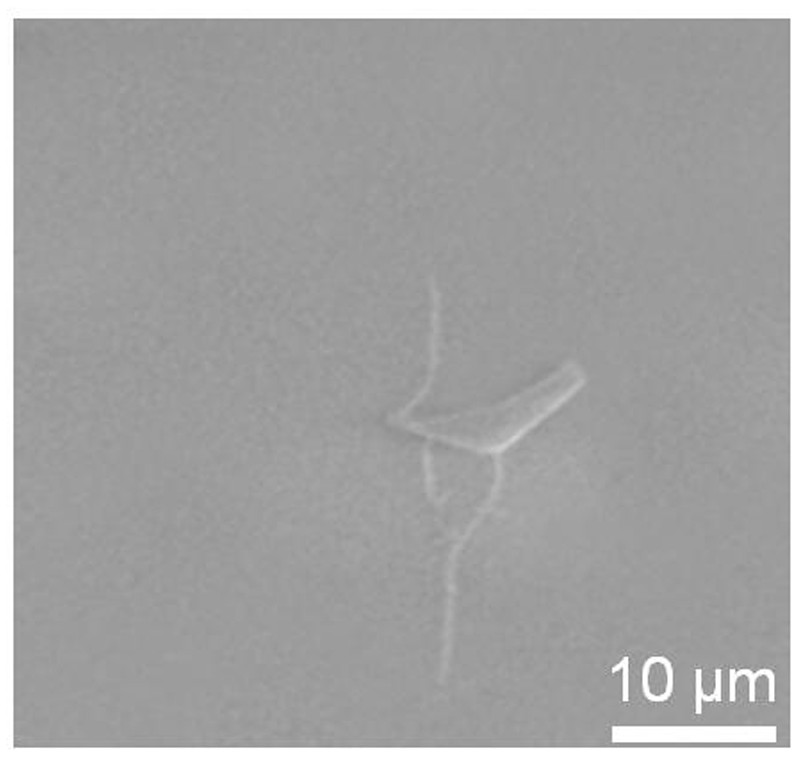

[0058] in SiO 2 Carbon nanotubes are grown on a / Si substrate with single-layer graphene as a catalyst. see figure 1 shown.

[0059] The specific steps are:

[0060] Step 1, choose SiO 2 / Si substrate, cut it into 6mm × 6mm size, and preprocess this substrate, the steps are as follows:

[0061] 1), ultrasonically clean the growth substrate in ultrapure water, acetone, ethanol, and ultrapure water in turn;

[0062] 2), dry with high-purity nitrogen;

[0063] Step 2, in the treated SiO 2 The graphene is mechanically exfoliated on the / Si growth substrate, and the number of layers is one. (height map such as Figure 3b )

[0064] Step 3, growing carbon nanotubes on the substrate with graphene.

[0065] The growth substrate with single-layer graphene obtained in step 2 is placed in a chemical vapor deposition system, and the temperature rise rate of 40°C / min under argon protection is heated to a growth temperature of 830°C, and the argon gas flow rate is 300sccm. Contin...

Embodiment 2

[0068] in SiO 2 Carbon nanotubes are grown on a / Si substrate with three-layer graphene as a catalyst. refer to Figure 4 shown.

[0069] Step 1 is the same as Step 1 in Embodiment 1.

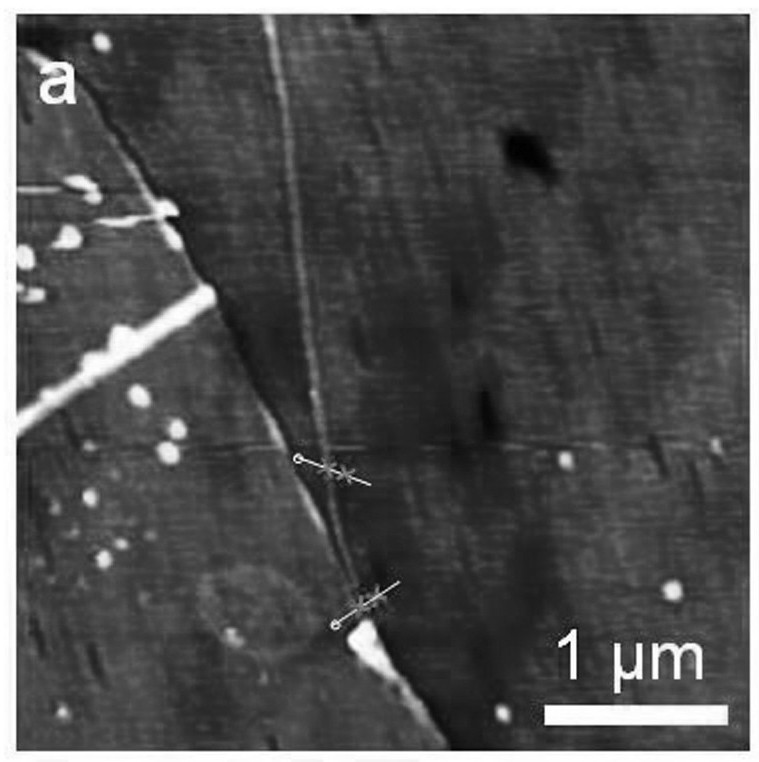

[0070] Step 2, in the treated SiO 2 / Mechanical exfoliation of graphene on Si growth substrate, the number of layers is three (the height map is shown in Figure 5b ). Specifically, 5a, 5b, and 5c are the characterization diagrams of the growth results in Example 2, wherein Figure 5a for the AFM map, Figure 5b is the height curve of graphene, Figure 5c is the height curve of single-walled carbon nanotubes.

[0071] Step 3, growing carbon nanotubes on the substrate with graphene.

[0072] The growth substrate with single-layer graphene obtained in step 2 was placed in a chemical vapor deposition system, and the temperature was increased to a growth temperature of 830 °C at a heating rate of 40 °C / min under the protection of argon gas, and the flow rate of argon gas was 300 sccm. Con...

Embodiment 3

[0074] Carbon nanotubes were grown on ST-cut quartz substrate with single-layer graphene as catalyst.

[0075] Step 1, select ST-cut quartz substrate, pretreat it, and process the growth substrate including the following steps:

[0076] 1), ultrasonically clean the growth substrate in ultrapure water, acetone, ethanol, and ultrapure water in turn;

[0077] 2), dry with high-purity nitrogen;

[0078] 3), put the cleaned substrate into a muffle furnace, anneal at high temperature in air, raise to 900 °C for 2 h, hold at 900 °C for 8 h, then cool down to 300 °C for 10 h, and cool down naturally;

[0079] In step 2, different layers of graphene are mechanically peeled off on the treated ST-cut quartz growth substrate, and the number of layers is 1-10 layers.

[0080] Step 3, growing carbon nanotubes on the substrate with graphene.

[0081] The growth substrate with single-layer graphene obtained in step 2 was placed in a chemical vapor deposition system, and the temperature was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com