A method for efficiently preparing skutterudite thermoelectric materials by laser

A technology of thermoelectric materials and skutterudite, which is applied in the field of efficient preparation of skutterudite thermoelectric materials, can solve problems such as the difficulty in accurately controlling the composition content of the final block sample, fluctuations in material performance, and volatilization of large Sb phases, and shorten the preparation cycle , low equipment requirements, and the effect of reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

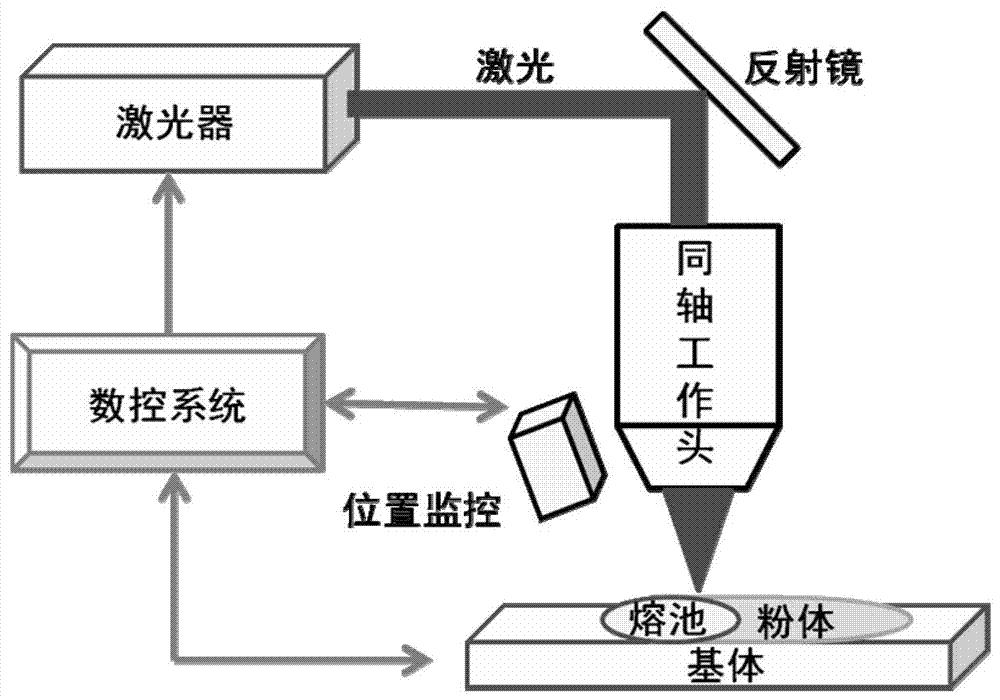

Method used

Image

Examples

Embodiment 1

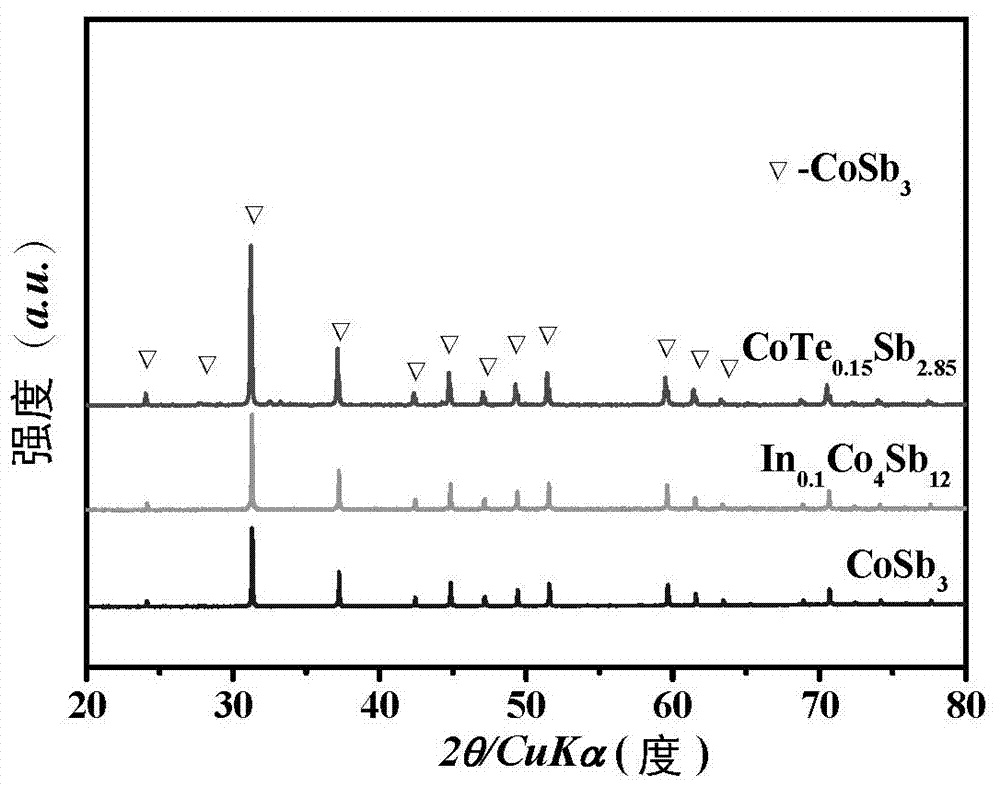

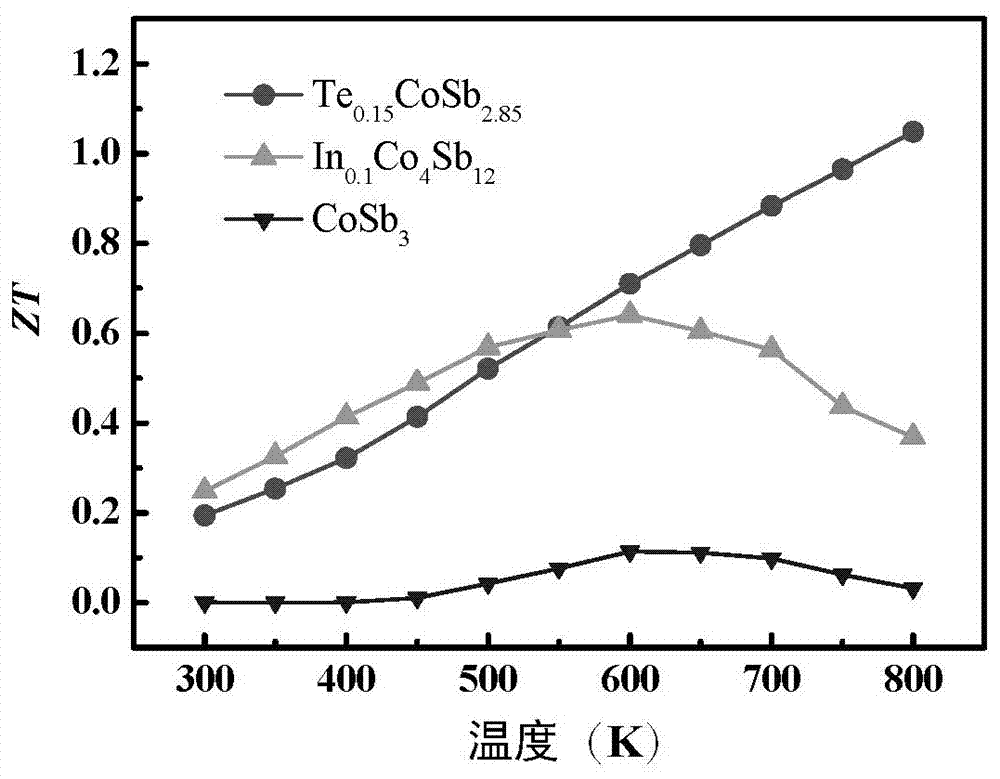

[0035] Sutterudite (CoSb 3 ) rapid preparation method of thermoelectric material laser melting / SPS, the specific steps are as follows:

[0036] (1) Use 200-mesh sieve powdered Co and Sb as raw materials, according to the chemical formula CoSb 3 Weighing; mix the weighing raw materials evenly in the grinding bowl, then spread the powder on the graphite substrate with a depth of 1mm, and place it in the processing chamber;

[0037] (2) Use argon-hydrogen mixed gas to wash the processing chamber, repeat 3 times, and finally the air pressure in the chamber is 0.12MPa;

[0038] (3) Adjust the laser process parameters, utilize the laser to melt the powder, and as the laser spot moves, the molten powder solidifies; due to the rapid cooling of the above-mentioned melt (10 4 ~10 5 K / s), the ingot grain structure is fine after condensation, and the segregation size is effectively controlled. The segregation size of different samples is similar, about 10 μm, which is much smaller tha...

Embodiment 2

[0041] Tellurium-doped skutterudite (expressed as CoSb 2.85 Te 0.15 、 Te 0.15 CoSb 2.85 or CoTe 0.15 Sb 2.85 ) rapid preparation method of thermoelectric material laser melting / SPS, the specific steps are as follows:

[0042] (1) Use 200-mesh sieve powdered Co, Sb, and Te simple substances as raw materials, according to the chemical formula CoTe 0.15 Sb 2.85 Weighing; mix the weighing raw materials evenly in the grinding bowl, then spread the powder on the graphite substrate with a depth of 1mm, and place it in the processing chamber;

[0043] (2) Use argon-hydrogen mixed gas to wash the processing chamber, repeat 3 times, and finally the air pressure in the chamber is 0.12MPa;

[0044] (3) Adjust the laser process parameters, utilize the laser to melt the powder, and as the laser spot moves, the molten powder solidifies; due to the rapid cooling of the above-mentioned melt (10 4 ~10 5 K / s), the ingot grain structure is fine after condensation, and the segregation siz...

Embodiment 3

[0047] Indium filled skutterudite (In 0.1 co 4 Sb 12 ) rapid preparation method of thermoelectric material laser melting / SPS, the specific steps are as follows:

[0048] (1) Using 200-mesh sieve powdered Co, Sb, and In simple substances as raw materials, according to the chemical formula In 0.1 co 4 Sb 12 weighing. Mix the weighing raw materials evenly in the grinding bowl, then spread the powder on the graphite substrate with a depth of 1mm, and place it in the processing chamber;

[0049] (2) Use argon-hydrogen mixed gas to wash the processing chamber, repeat 3 times, and finally the air pressure in the chamber is 0.12MPa;

[0050] (3) Adjust the laser process parameters, utilize the laser to melt the powder, and as the laser spot moves, the molten powder solidifies; due to the rapid cooling of the above-mentioned melt (10 4 ~10 5 K / s), the ingot grain structure is fine after condensation, and the segregation size is effectively controlled. The segregation size of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com