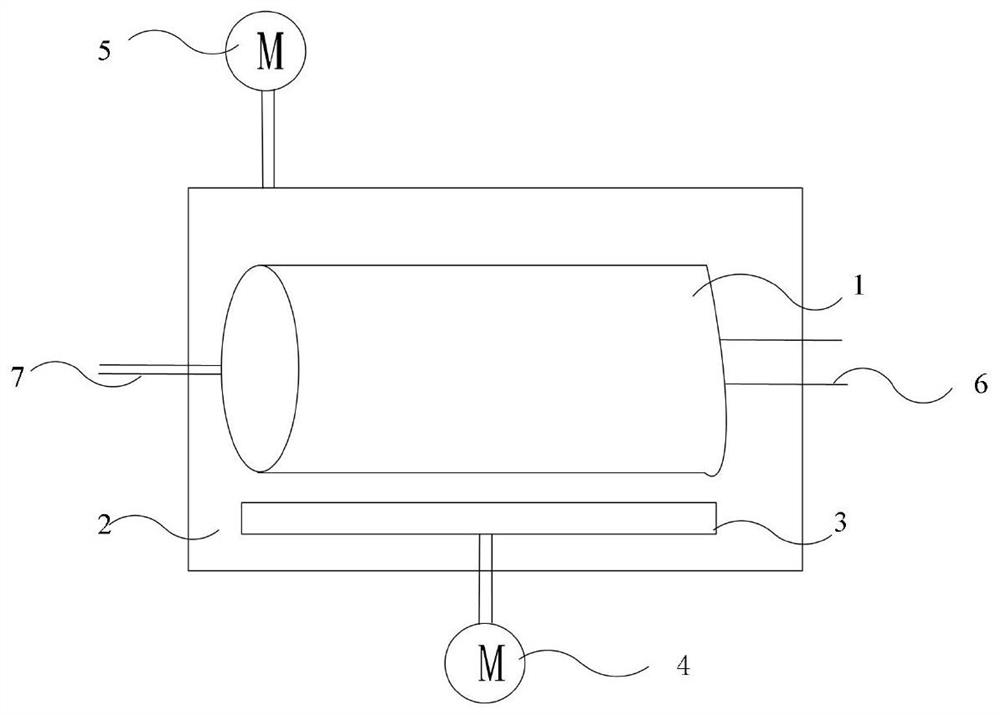

Control method of biomass pyrolysis gasifier

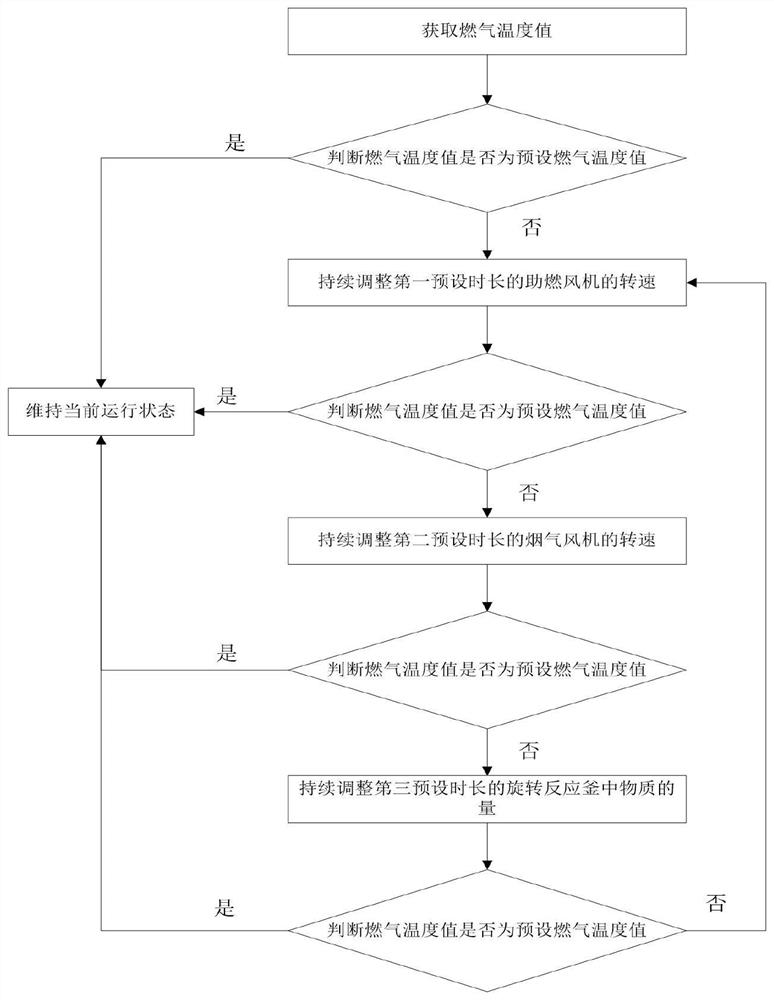

A technology of pyrolysis gasification and control method, which is applied in the gasification process, the feeding tool of the gasification device, and the manufacture of combustible gas, etc. Gasifier temperature fluctuations and other problems, to achieve the effect of easy temperature control, improved efficiency, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The biomass thermal unsteasing furnace is in the initial period of ignition. By combustion of combustion on the chain row, the biomass raw material such as a quantitative straw is delivered from the feed port to the reaction kettle, adjust the steering of the reaction kettle to the furnace and reactor. Heating, when the biomass thermal extract furnace reaches the pyrolytic gasification temperature of the biomass raw material, stop the addition of flammable products, preheating the biomass thermal default furnace, and is consumed by the thermal flulation reaction after preheating. The straw in the reactor is followed by repeated artificially charged, unloading, in order to perform thermal amplifiation to generate gas. During the operation of the biomass thermal extract, since the biomass such as straw has a certain amount of water, the temperature in the rotating reaction is reduced, resulting in the pyrolysis temperature, and the subsequent addition of flammable will cause ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com