Production method of low-greasiness direct drinking tea oil

A production method and greasy technology, applied in the direction of fat production, edible oil/fat, fat oil/fat refining, etc., can solve serious greasy feeling and other problems, and achieve the effect of significant industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

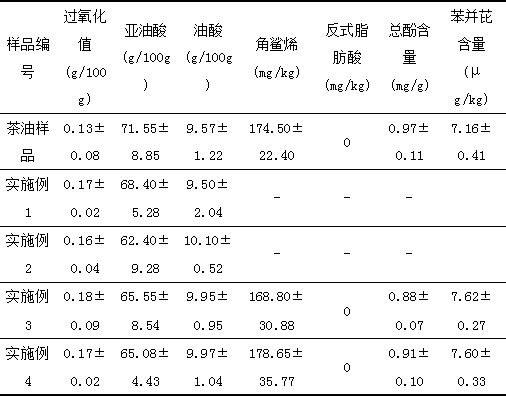

Examples

Embodiment 1

[0020] Example 1: A low-greasy straight-drink tea oil after moderate enzymolysis

[0021] The main raw material is pure tea seed oil extracted by pressing, and the steps of the preparation method are as follows:

[0022] Step 1: Add 10% volume of purified water and 2% mass of immobilized enzyme Lipozyme® 435 to the camellia oil, and mix well;

[0023] Step 2: Put the above system in a constant temperature shaker, mix and react at 40°C for 6 h;

[0024] Step 3: After the reaction is completed, the immobilized enzyme is removed by filtration or centrifugation;

[0025] Step 4: After removing water by vacuum distillation at 50-60°C, filter again with suction.

Embodiment 2

[0026] Example 2: A low-greasy direct-drinking tea oil with moderate heat preservation treatment

[0027] The main raw material is pure tea seed oil extracted by pressing, and the steps of the preparation method are as follows:

[0028] Step 1: Select a 25mL glass hydrolysis tube (outer diameter 25mm, inner diameter 18mm), and fill it with 25mL tea oil;

[0029] Step 2: Put the above-mentioned camellia oil in a constant temperature oven and keep it warm at 110°C for 4.5 minutes;

[0030] Step 3: Take it out and cool it at 8°C.

Embodiment 3

[0031] Example 3: A low-greasy direct-drinking tea oil with moderate heat preservation after enzymatic hydrolysis

[0032] The main raw material is pure tea seed oil extracted by pressing, and the steps of the preparation method are as follows:

[0033] Step 1: Add 10% volume of purified water and 2% mass of immobilized enzyme to the camellia oil, and mix well;

[0034] Step 2: Put the above system in a constant temperature shaker, mix and react at 40°C for 6 hours;

[0035] Step 3: After the reaction is completed, the immobilized enzyme is removed by filtration or centrifugation;

[0036] Step 4: After removing water by vacuum distillation at 50-60°C, filter again with suction.

[0037] Step 5: Select a 25 mL glass hydrolysis tube (outer diameter 25 mm, inner diameter 18 mm) and fill it with 25 mL camellia oil;

[0038] Step 6: Put the above-mentioned camellia oil in a constant temperature oven and keep it warm at 110°C for 4.5 minutes; after the heat preservation is over,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com