Deoxidation method of aluminum-killed silicon-containing steel

A silicon deoxidizer and sedation technology, applied in the field of deoxidation of aluminum-killed silicon-containing steel, can solve problems such as water plugging, inclusions, and no downflow, and achieve the effects of improving molten steel quality, reducing deoxidation costs, and improving molten steel purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

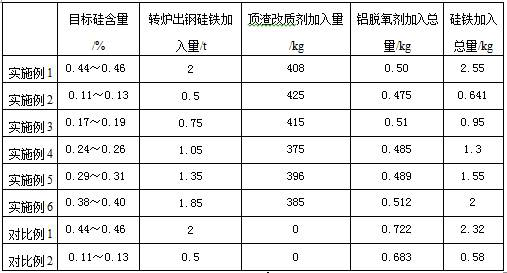

[0017] The mass percent content of silicon in the steel grades produced in Examples 1-6 is shown in Table 1. The smelting process includes converter smelting and LF furnace refining processes. The production steps are:

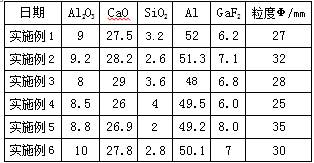

[0018] ①Converter process: During the tapping process of the converter, a silicon-containing deoxidizer is used for deoxidation, and no aluminum block is put into the molten steel. The amount of silicon-containing deoxidizer added is shown in Table 1. After tapping, add ladle top slag modifier to the surface of molten steel without feeding aluminum wire. The amount of top slag modifier added is shown in Table 1, and the composition and mass percentage of top slag modifier are shown in Table 2. The particle size of the top slag modifier is shown in Table 2.

[0019] ② Refining process: molten steel is refined in LF furnace, and aluminum deoxidizer is used for deoxidation and slagging.

[0020] The silicon-containing deoxidizer in the converter process can be d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com