Large-span steel-concrete structure and its construction method

A technology of concrete structure and construction method, which is applied in building construction, on-site preparation of building components, and processing of building materials, etc., can solve the problems of large demand for supporting columns, laborious installation of supporting columns, and poor use coupling, etc. The effect of supporting construction is convenient, improving the reliability of the support, and having good flexibility in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

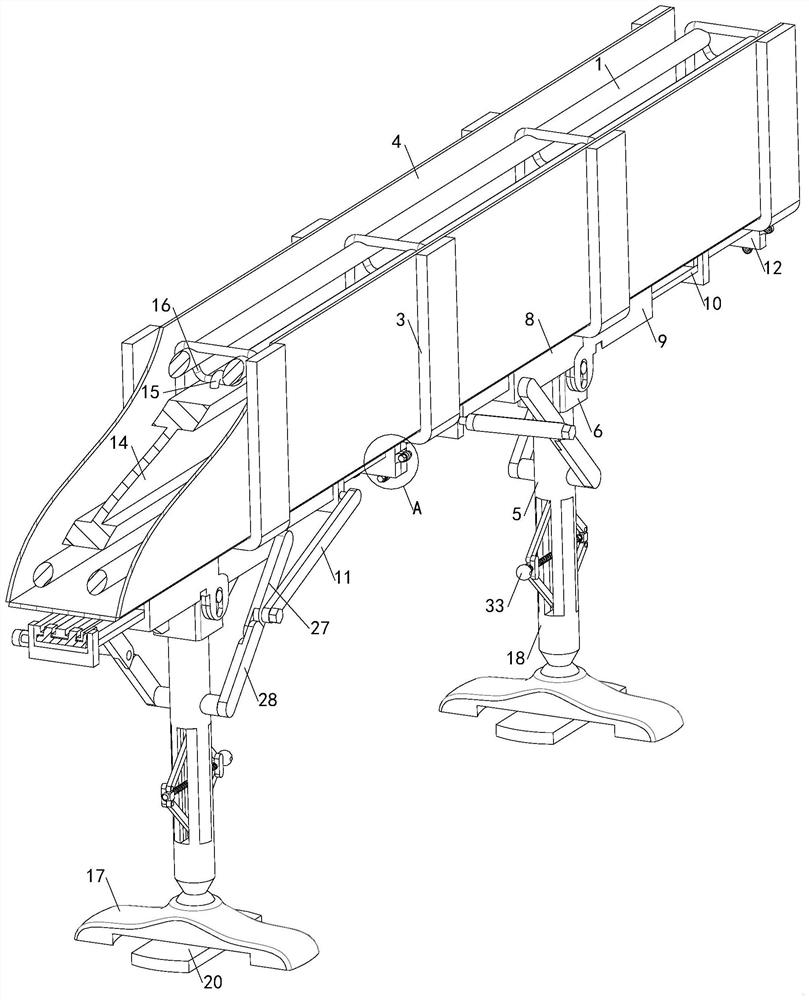

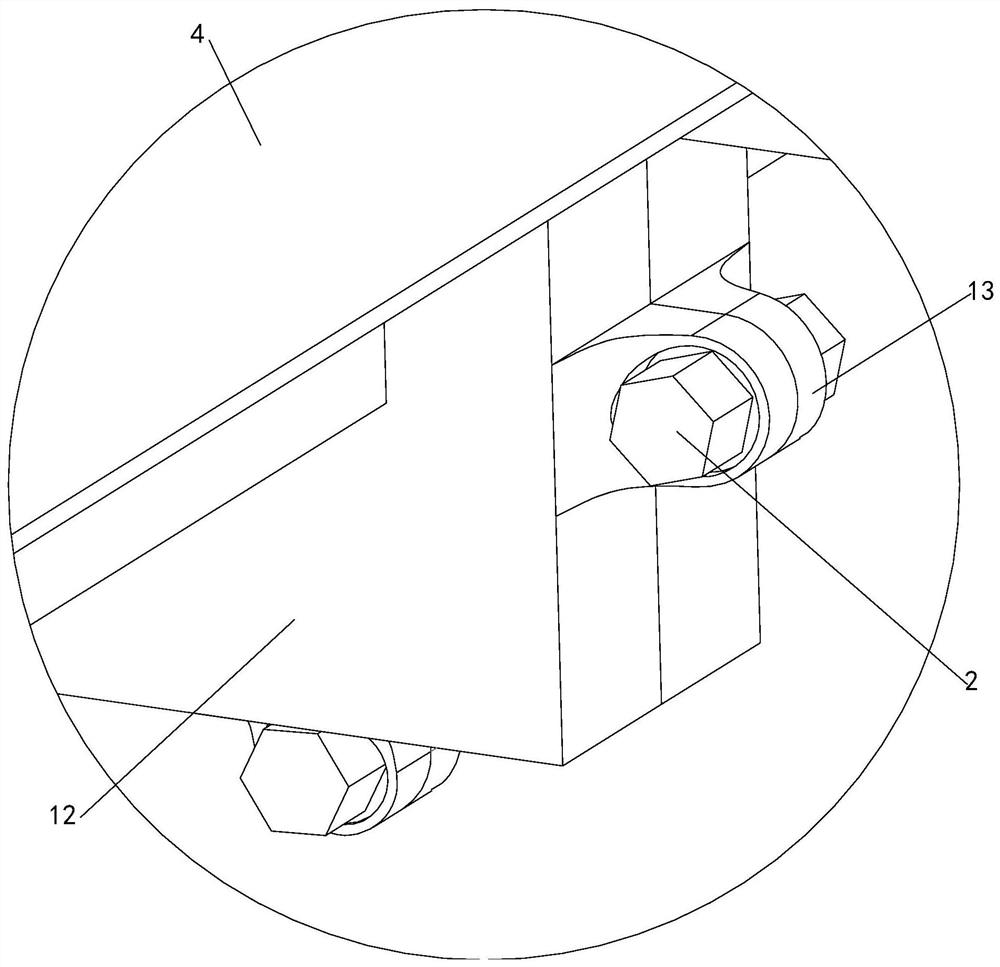

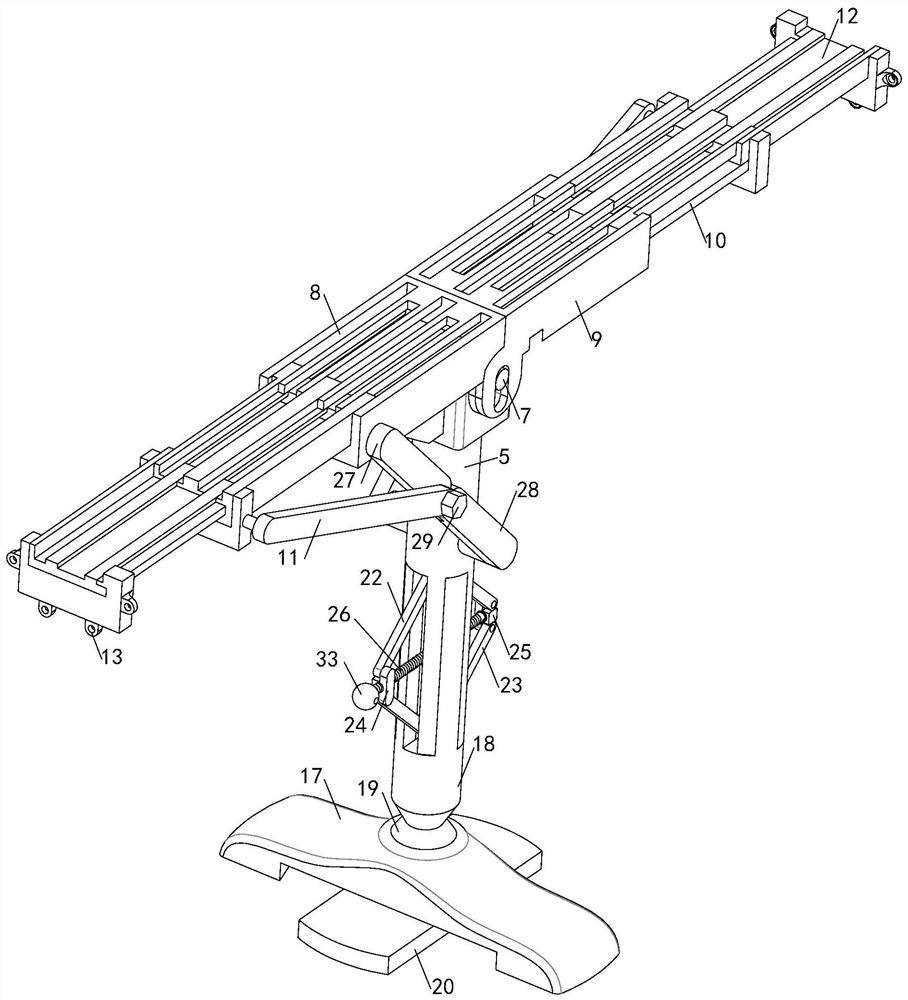

[0039] see Figure 1-8 , a large-span steel-concrete structure, including a steel structure 1, and a plurality of support structures, each adjacent two support structures of the multiple support structures are connected by multiple bolts 2, and multiple support structures are installed on the multiple support structures. U-shaped stirrups 3, a formwork 4 is installed in the U-shaped stirrups 3, a steel structure 1 is set in the formwork 4, an auxiliary steel structure is installed in the steel structure 1, and the auxiliary steel structure includes an I-beam 14, and the I-beam 14 is set In the reinforced structure 1, the top and bottom ends of the I-beam 14 are fixedly connected with hanging rings 15, and the auxiliary connecting steel bars 16 are arranged in the hanging rings 15. Structural strength increases the load it can carry. The support structure includes a support body structure and a support seat structure. The support body structure includes a lifting upper column 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com