Deep-buried roadway rock burst danger relieving method

A roadway and roadway support technology, which is applied in the direction of tunnels, tunnel linings, underground chambers, etc., to achieve the effect of quickly relieving danger, reducing possibilities, and simplifying on-site operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

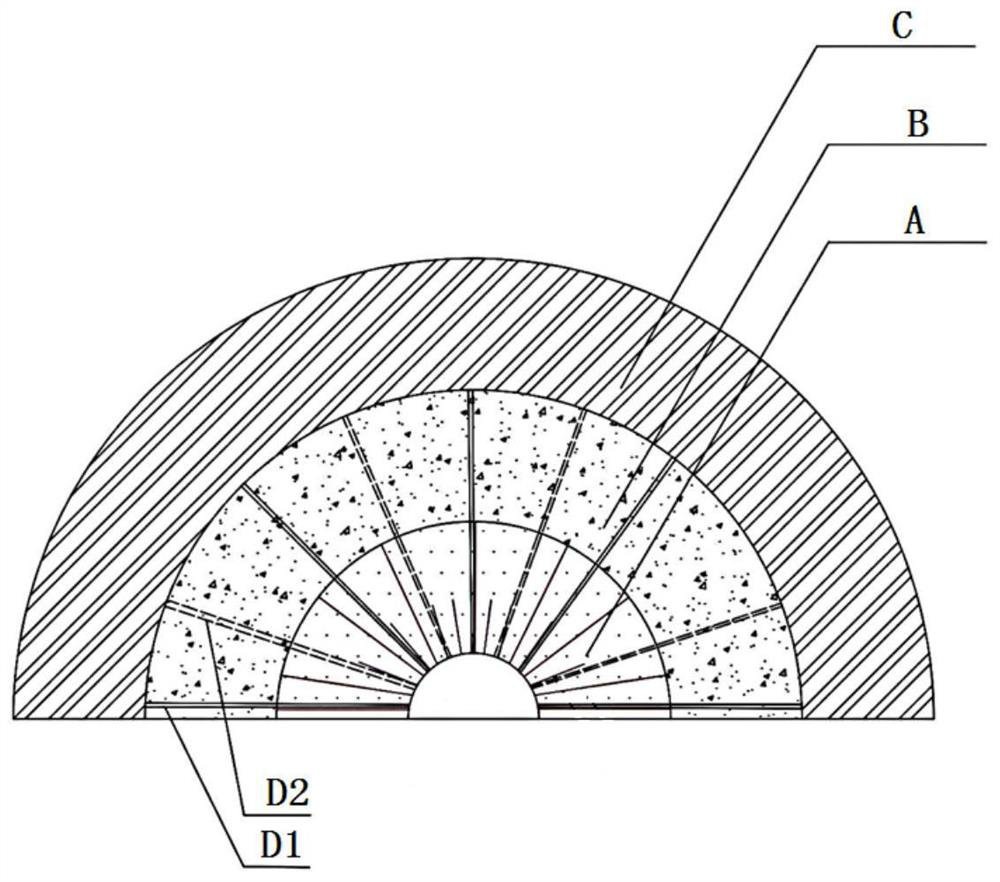

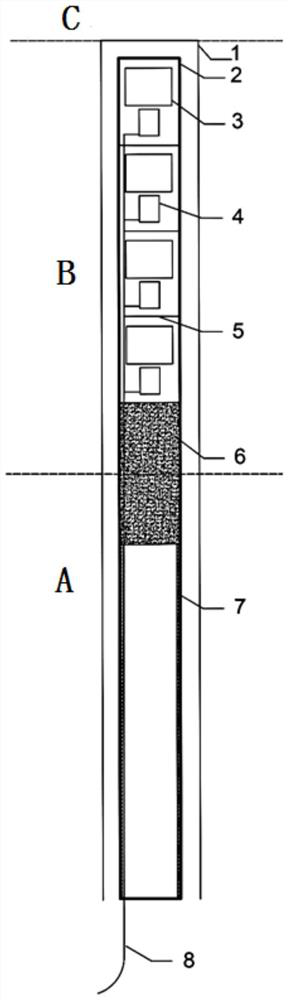

[0041] Such as figure 1 as shown, figure 1 It is a schematic diagram of the strong, weak and strong anti-scouring structure of the roadway section, and it is the ideal structure of the roadway anti-scouring that is prepared to be realized by the present invention. Three-layer strong and weak structure, the roadway support layer A is used to support the stability of the roadway, and its thickness is 1 to 2 times the height of the roadway; the weak energy-absorbing layer B is a soft and broken structure that scatters and absorbs shock waves, The thickness is 1 to 2 times the height of the roadway, and the hard original rock layer C is the undisturbed rock mass outside the weak energy-absorbing layer.

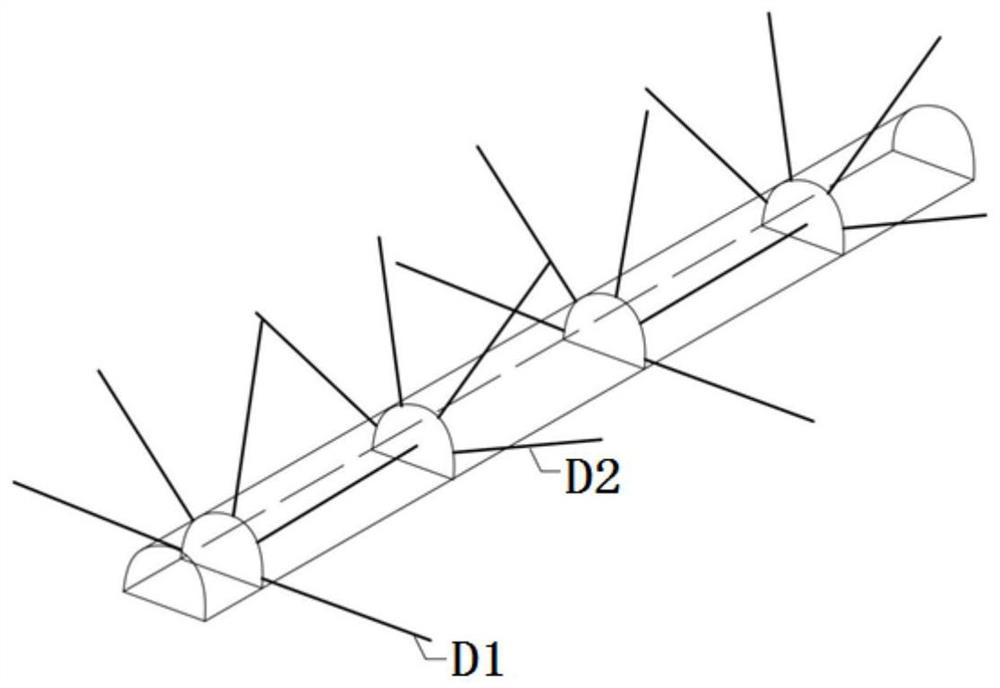

[0042] figure 2 It is a schematic diagram of the layout of blasting pressure relief holes in different sections of the roadway. In roadways with rockb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com