Tunnel escape pipeline and construction method thereof

A technology for escape pipes and escape pipes, which is applied in the construction supply of tunnel face, escape integrated tunnel escape pipes and its construction field, which can solve the problems of disorderly layout, low efficiency, easy loss, etc., and achieve low cost and simple structural design , The effect of fast disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

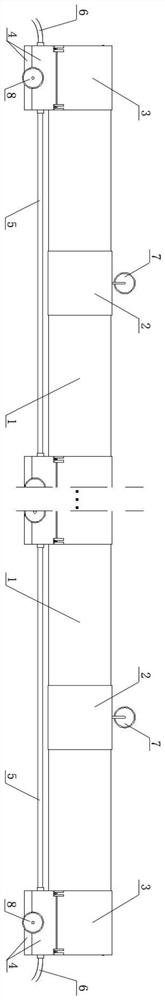

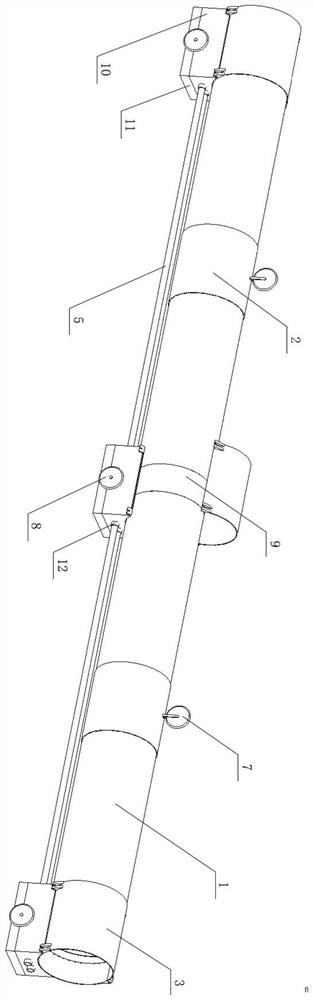

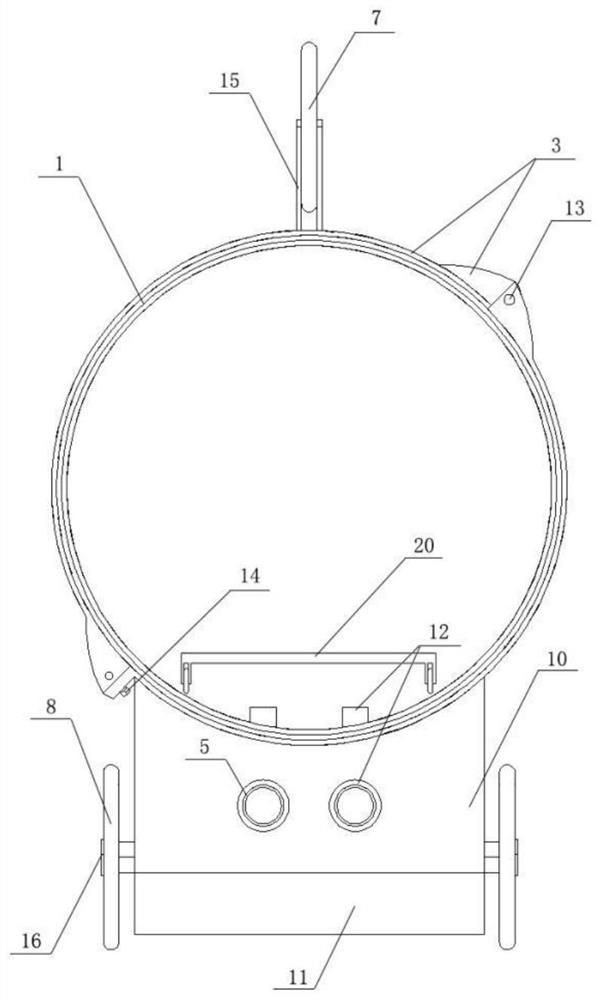

[0052] combine Figure 1 to Figure 5 As shown, this embodiment provides a tunnel escape pipeline, which includes a number of end-to-end escape pipe joints 1 erected between the secondary lining of the tunnel and the tunnel face, a connecting assembly 3, a support seat 4 and a supply In the pipeline, the two ends of the escape pipe joint 1 are respectively provided with connecting sections 21, and the connecting assembly 3 is arranged at the connecting section 21, which is used to connect two adjacent escape pipe joints 1, and is also used for the escape pipe joints 1 at the first and last ends The connection section 21, the support seat 4 is arranged at the bottom of the connection assembly 3, used to support the connection assembly 3 and the escape pipe joint 1, and the support seat 4 is provided with adjustable moving devices on both sides of the extension direction of the escape pipe joint 1, which can realize The movement and fixation of the support base 4, combined with t...

Embodiment 2

[0063] Embodiment two is basically the same as embodiment one, and its difference is: combine Figure 1 to Figure 4 As shown, this embodiment also provides a tunnel escape pipeline. In order to facilitate the installation of the supply pipeline, this embodiment is provided with a tee connector 12 in the support seat 4, and the supply pipeline includes several pipeline sections 5. In the embodiment, the pipeline section 5 has the same number as the escape pipe joint 1 and is arranged in parallel, wherein the two connection ends of the three-way connector 12 are in the same direction as the supply pipeline, so that the two connection ends of the three-way connector 12 respectively It is connected with the two adjacent pipeline sections 5, and the other connecting end of the tee connector 12 extends into the connection section 9 with the escape pipe joint through the reserved hole to directly form a branch pipeline. The tee connector 12 is pre-embedded in the support seat 4, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com