Filling body biaxial loading system based on uniaxial testing machine transformation and use method

A uniaxial test and filling technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of increasing filling costs and conservative structures, so as to reduce filling costs and improve The effect of stope stability and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] Aiming at the defects of the existing uniaxial strength testing system in characterizing the filling body strength, the present invention proposes a filling body biaxial loading system based on the transformation of the uniaxial testing machine and a usage method based on the original uniaxial testing machine. Not only can the original device be used to measure the uniaxial performance of the test piece, but also the lateral pressure can be added to the test piece to test the mechanical properties of the filling body under the biaxial loading condition.

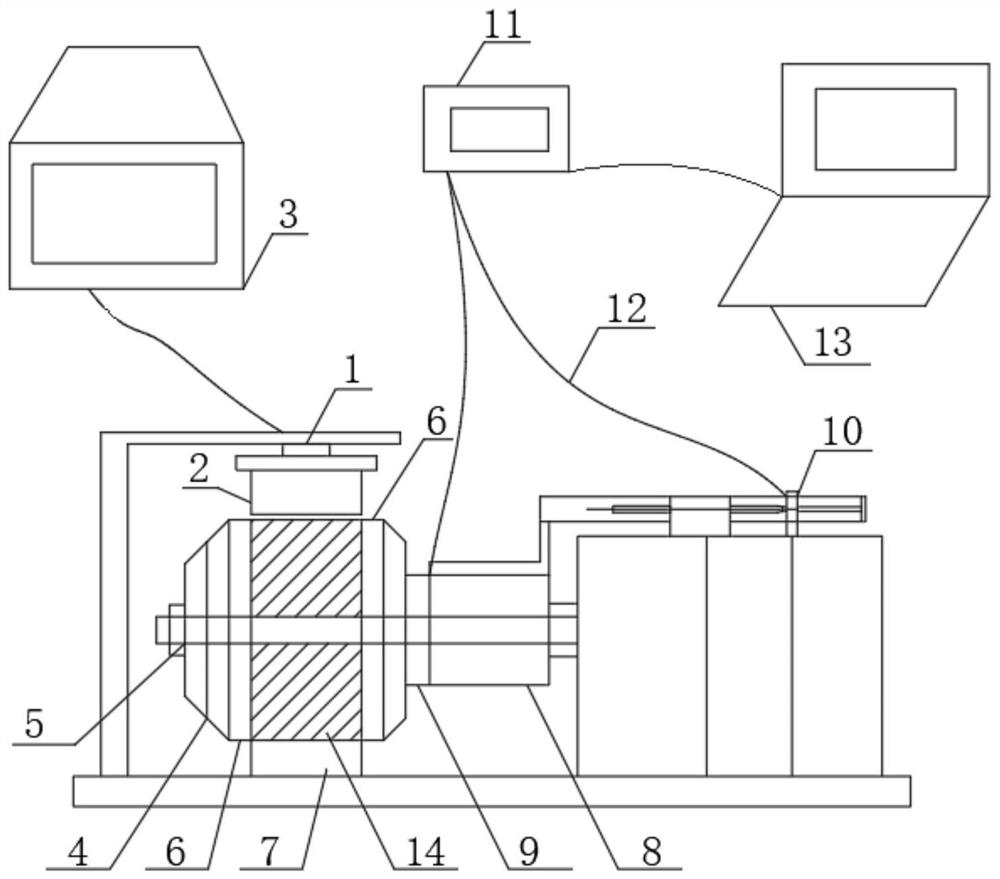

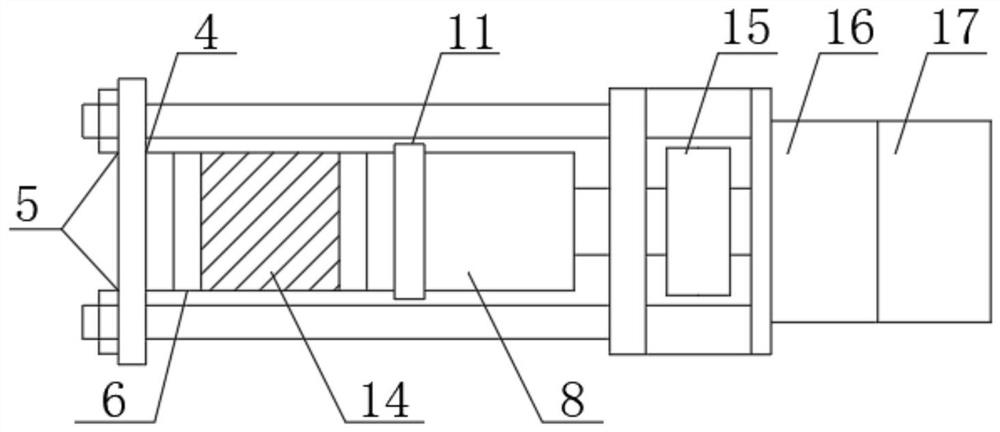

[0031] Such as figure 1 As shown, the system includes uniaxial testing machine 1, loading block 2, data acquisition and processing system 3 of uniaxial testing machine, reaction baffle 4, reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com