An intelligent vertical corn harvester and corn combine harvester

A technology for combine harvesters and headers, which is applied to headers, harvesters, agricultural machinery and implements, etc., can solve the problems of inaccurate picking, corn damage, and excessive corn impurities, and reduce the loss rate of harvesting and work efficiency. High and wide harvesting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

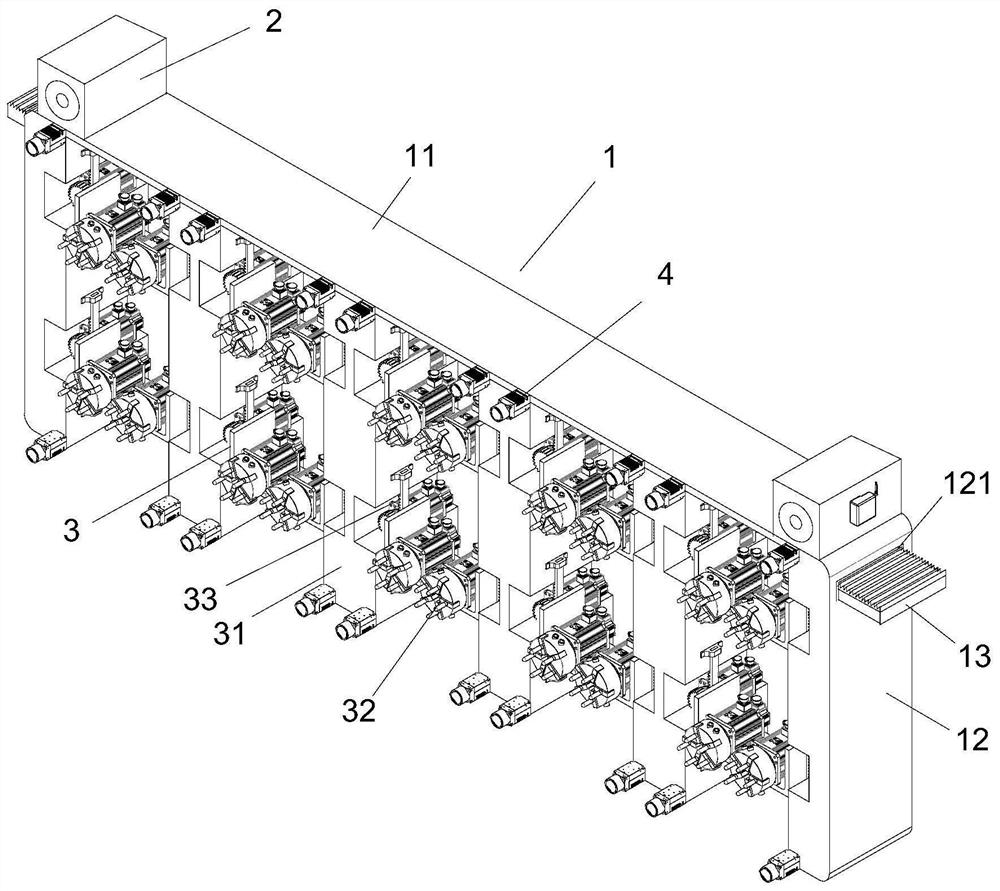

[0043] like figure 1 As shown, this embodiment provides an intelligent vertical corn harvesting platform, which includes: a platform 1, a beam driving mechanism 2, a rod breaking mechanism 3, a displacement sensor 5, an industrial camera 4, and an intelligent control module 100 .

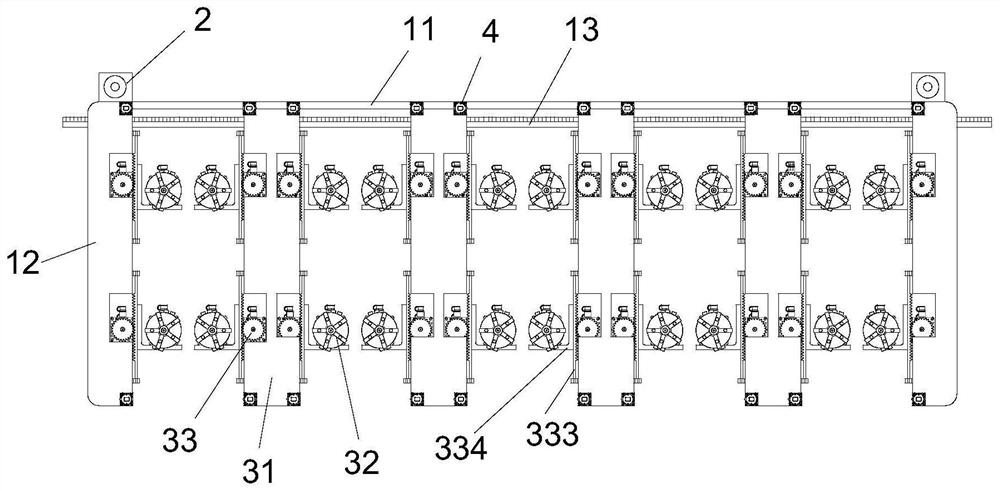

[0044] like Figure 7 As shown, the stand 1 is in the shape of "凵" with the opening downward, and includes a horizontal frame 11 and vertical frames 12 on both sides; the vertical frames 12 on both sides are provided with opposite first passageways at the ends close to the horizontal frame 11. In the hole 121 , the two first through holes 121 are provided with a movable beam 13 penetrating through, and the movable beam 13 is parallel to the beam 11 .

[0045] The beam driving mechanism 2 is installed on the platform 1 and is used to drive the movable beam 13 in the platform 1 to shuttle back and forth between the first through holes 121 in the two sets of vertical frames 12 .

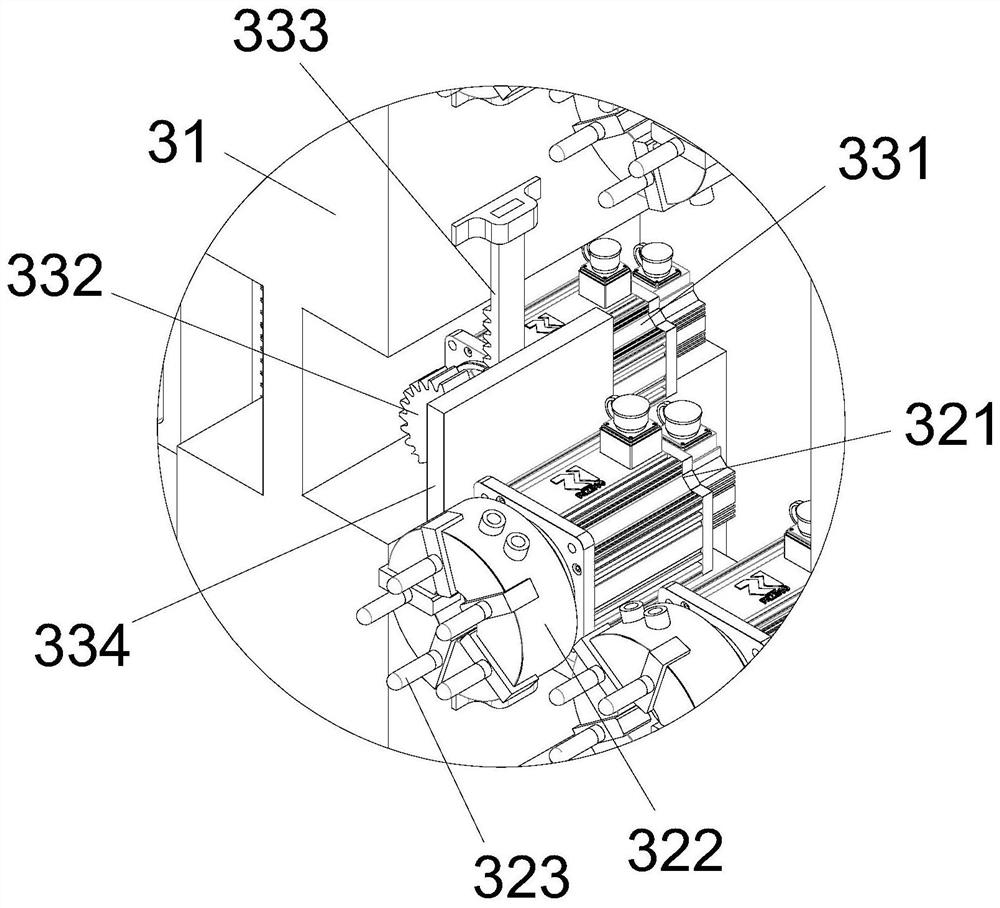

[0046] like figu...

Embodiment 2

[0067] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is: in this example, the number of movable crossbeams 13 in the harvesting platform is multiple, and each mounting frame 31 is connected with the corresponding movable crossbeam 13, and the movable crossbeam 13 It is movably connected with the cross frame 11 of the platform 1, and each movable cross beam 13 is connected with a corresponding cross beam driving mechanism 2, and the cross beam driving mechanism 2 is installed above the cross frame 11, and the cross frame 11 corresponds to the cross beam driving mechanism 2 There is a second through hole 111 in the downward communication direction at the position of each beam driving mechanism 2, which is electrically connected to the intelligent control module 100, and the intelligent control module 100 is used to independently control the running state of each beam driving mechanism 2, thereby adjusting The horizontal spacing between the m...

Embodiment 3

[0071] The present embodiment provides a kind of corn combine harvester, and this combine harvester uses as embodiment 1 or 2 intelligent vertical corn harvesting platform, finishes the harvest of corn; Combine harvester also comprises corn cob collection mechanism, corn cob collection mechanism It includes a conveying mechanism and a throwing mechanism; one end of the conveying mechanism is under the harvesting platform, and the other end extends to the other end opposite to the corn harvesting operation direction, and the throwing mechanism is used to throw the corn cobs conveyed by the conveying mechanism to the combined harvesting the rear or sides of the machine.

[0072] At the same time, the tail end of the combine harvester along the harvesting direction also includes a straw crushing and collecting mechanism, which is used to crush the corn stalks after picking the corn cobs, and collect the crushed straws.

[0073] In the combine harvester, after the corn cobs are br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com