Preparation method of green food quick-frozen green sword beans

A technology of green food and green beans, which is applied in food freezing, food processing, food science, etc., can solve the problems of uneven processing technology, loss of green beans' nutritional elements, and loss of taste, so as to achieve less loss of nutrients, Avoid bad taste and accelerate the loss of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

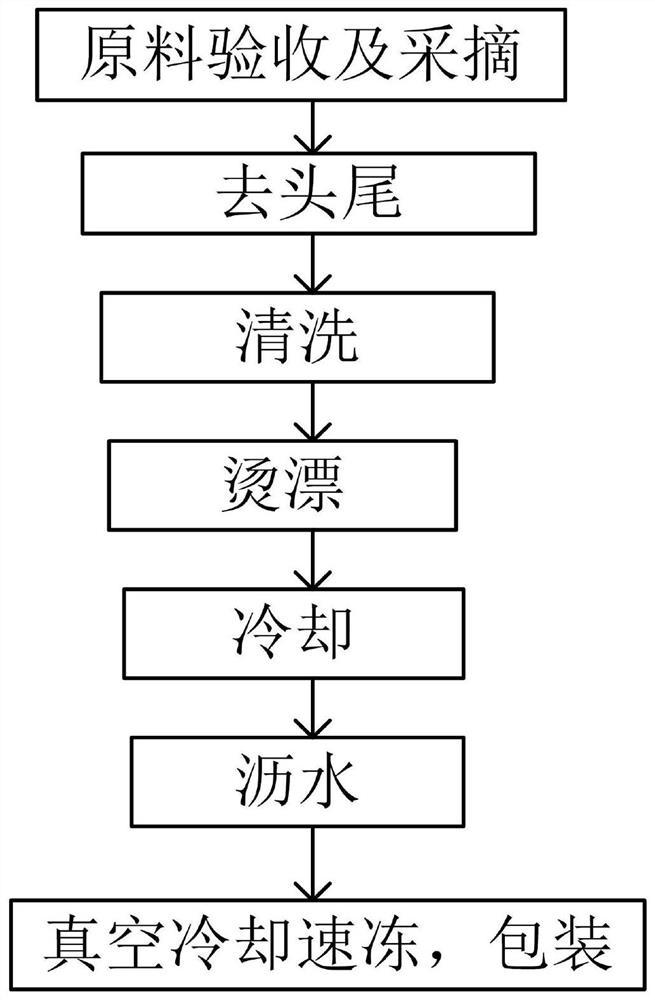

[0030] The invention provides a kind of preparation method of green food quick-frozen green beans, comprising the following steps:

[0031] (1) Raw material acceptance and picking: green beans are tested one week before picking, and picked after passing the test;

[0032] (2) Remove the head and tail: remove the head and tail of the green beans;

[0033] (3) Processing: the green beans obtained in step (2) are successively cleaned, blanched, cooled, drained, then vacuum-cooled and quick-frozen, and packaged.

[0034] In the present invention, in the step (1), the green beans before picking need to meet the standard of NY / T1406-2018.

[0035] In the present invention, in the step (2), the length removed from both ends of the green beans is 0.5 to 1 cm; preferably 0.7 to 0.8 cm. c m; more preferably 0.75 c m.

[0036] In the present invention, the blanching: putting the green beans in water at 58-65°C for 10-20s for the first blanching; preferably putting them in water at 60...

Embodiment 1

[0051] A preparation method of green food quick-frozen green beans, comprising the following steps:

[0052] (1) Raw material acceptance and picking: green beans are tested one week before picking, and must meet the standards of NY / T1406-2018, and pick after passing the test;

[0053] (2) Remove the head and tail: Remove the head and tail of the green beans, and the length removed from both ends is 0.5cm;

[0054] (3) processing: the green beans obtained in step (2) are cleaned;

[0055] (4) Put the cleaned green beans into 58°C water for 10s for the first blanching; then put them in 94°C water for 45s for the second blanching, and stir; is 7.5;

[0056] (5) Cool the green beans after blanching, spray with water to make the center temperature of the green beans drop to 50°C, then place them in 10°C water and cool until the center temperature of the green beans is 25°C, then Place in 0°C water to lower the temperature of the green beans to 7°C;

[0057] (6) Place the cooled...

Embodiment 2

[0060] A preparation method of green food quick-frozen green beans, comprising the following steps:

[0061] (1) Raw material acceptance and picking: green beans are tested one week before picking, and must meet the standards of NY / T1406-2018, and pick after passing the test;

[0062] (2) Remove the head and tail: Remove the head and tail of the green beans, and the length of the removed ends is 1cm;

[0063] (3) processing: the green beans obtained in step (2) are cleaned;

[0064] (4) Put the cleaned green beans in water at 65°C for 20s for the first blanching; then put them in water at 98°C for 90s for the second blanching, and stir; the pH of the two blanching water is 8.3;

[0065] (5) Cool the green beans after blanching, spray with water to make the center temperature of the green beans drop to 60°C, then place them in 25°C water to cool until the center temperature of the green beans is 30°C, and then Place in 10°C water to lower the temperature of the green beans t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com