A continuous mixing fly ash processing equipment

A processing equipment and mixing technology, applied in grain processing, mixers, chemical/physical processes, etc., can solve problems such as multiple dry lumps, and achieve the effect of good mixing quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

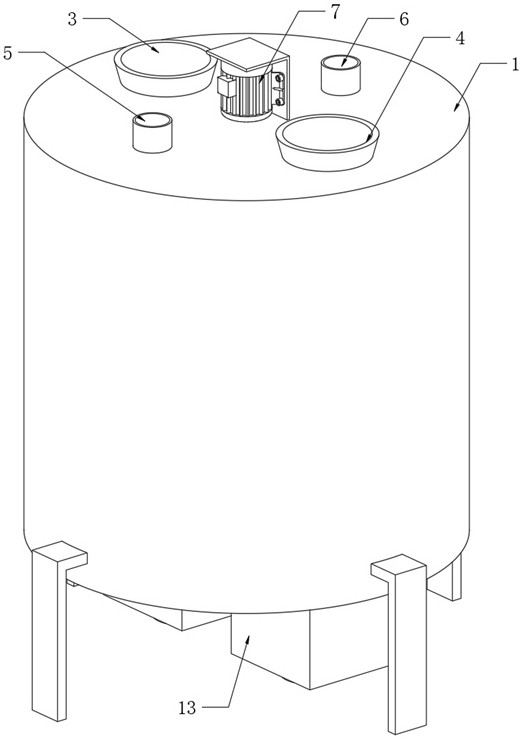

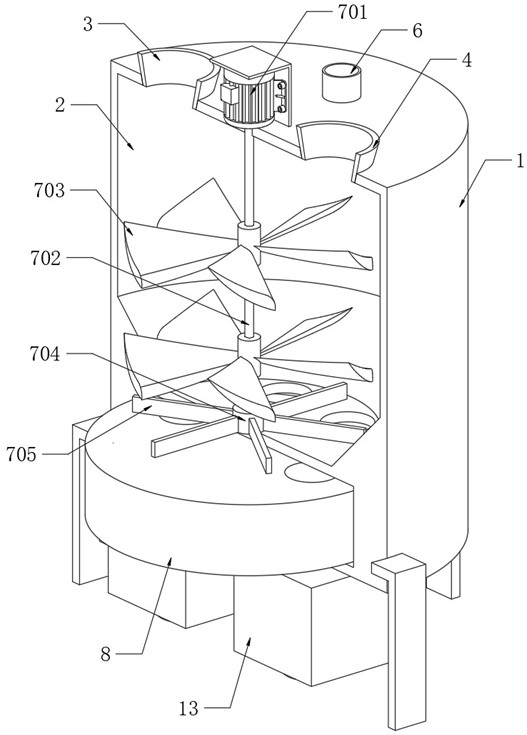

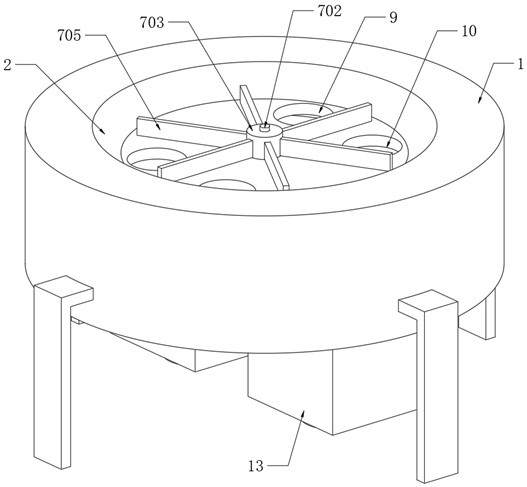

[0022] refer to figure 1 , figure 2 , image 3 and Figure 6 , a continuous mixing fly ash processing equipment, including a box body 1, a mixing chamber 2 for mixing fly ash and cement is provided in the box body 1, and the lower part of the mixing room 2 is bucket-shaped, and the mixing chamber The chamber 2 is provided with a mixing mechanism 7 for stirring fly ash and cement, and a cylindrical transfer tank 801 is vertically provided inside the box body 1, and the transfer tank 801 is located directly below the mixing chamber 2, and the transfer tank 801 There is a transfer mechanism 8 inside, and two first communication holes 9 and two second communication holes 10 are vertically opened between the inner top wall of the transfer tank 801 and the inner bottom wall of the mixing chamber 2, and the two first communication holes Both the hole 9 and the second communication hole 10 are arranged symmetrically about the center of the transfer tank 801, and two first discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com