Casting draining structure for aluminum alloy die casting of engine suspension bracket

A suspension bracket and aluminum alloy technology, which is applied in the field of parts processing equipment, can solve the problems that the surface of parts is not clean, cannot be processed, and only one or two small parts can be processed at the same time, so as to improve the cleanliness, improve efficiency, and improve The effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

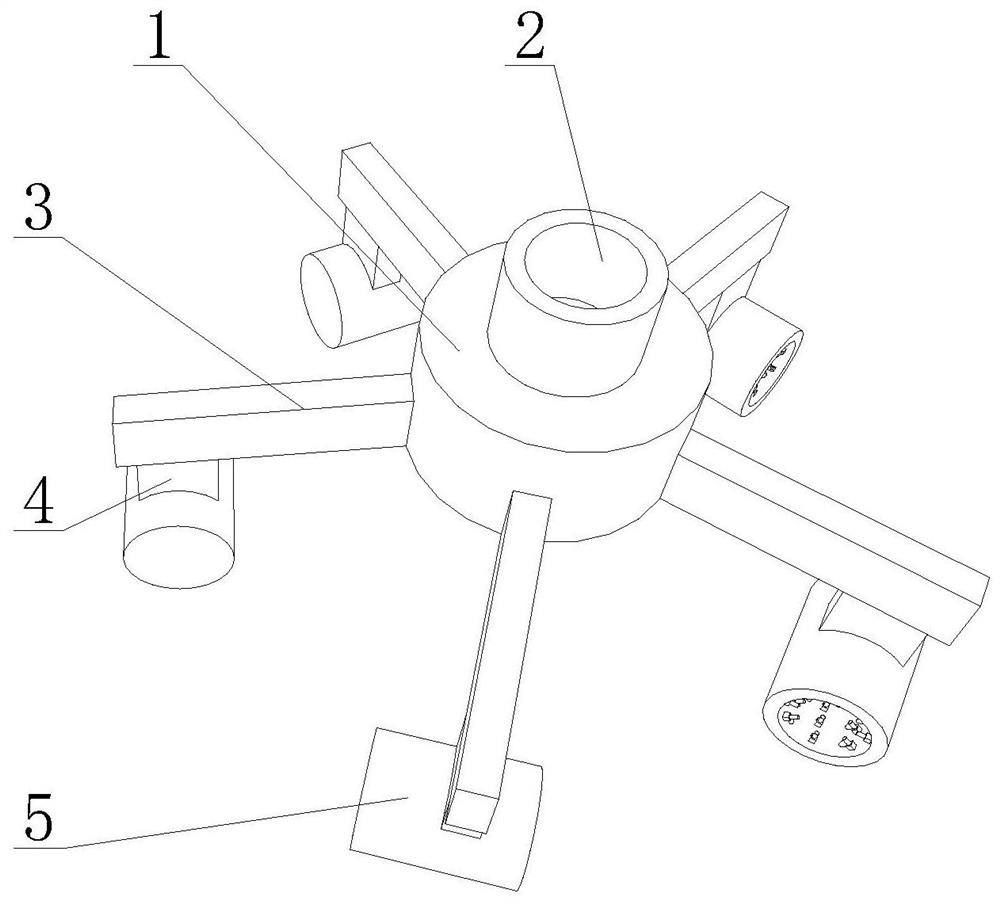

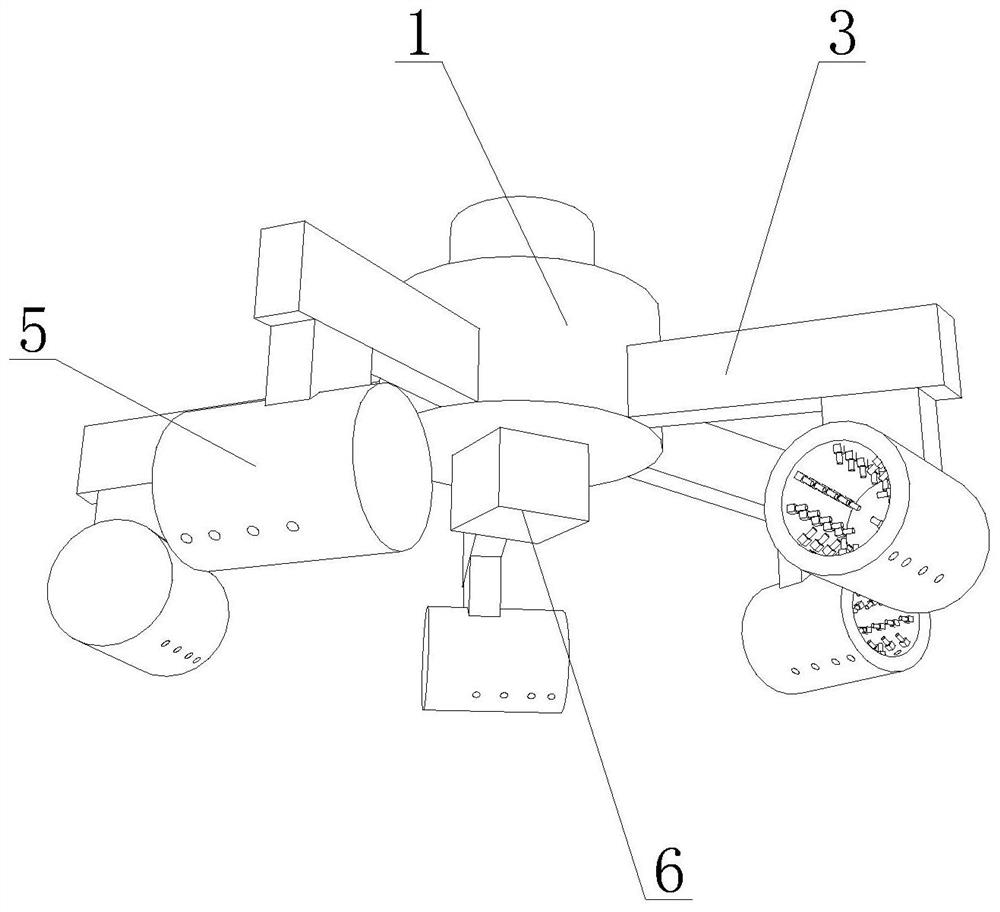

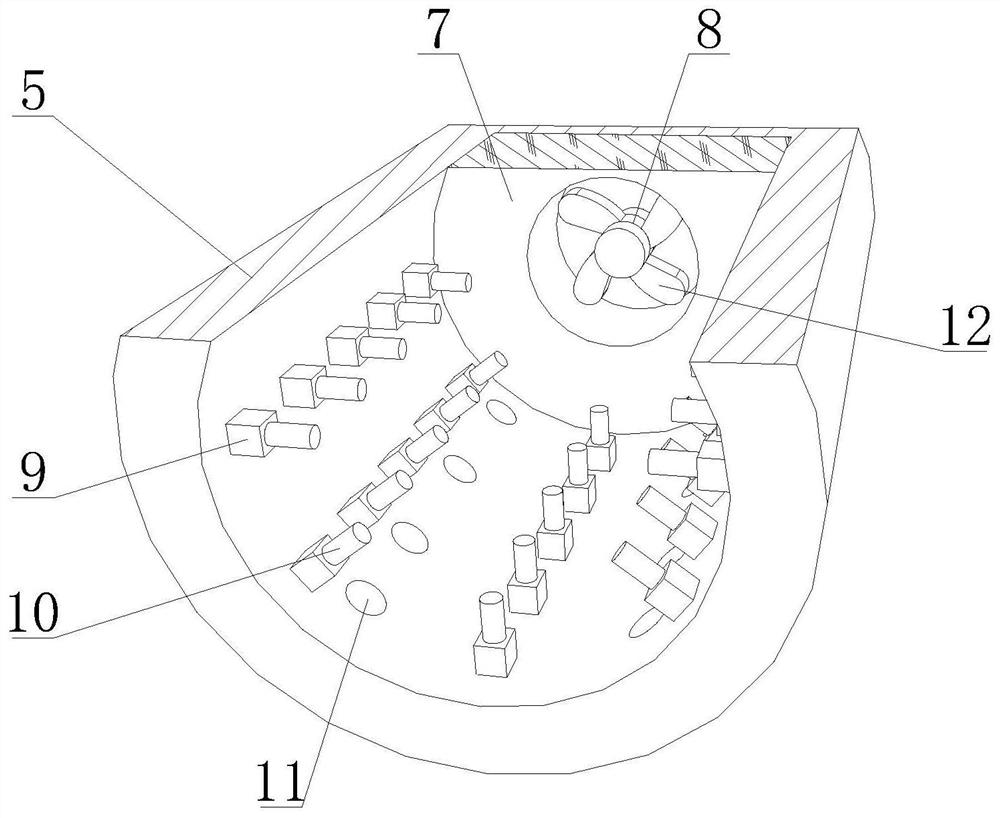

[0032] Such as Figure 1-Figure 5 As shown, the present invention provides an engine suspension bracket aluminum alloy die-casting pouring structure, including a pouring structure main body 1 and a fixed drain pipe 2, and the top of the pouring structure main body 1 is fixedly installed with a fixed drain pipe 2, pouring The surface of the row structure main body 1 is provided with a draining inclined channel pipe 3, and the bottom of the draining inclined channel pipe 3 is fixedly installed with a fixedly connected draining plate 4, and the bottom of the fixedly connected draining plate 4 is provided with a watering and draining blow dryer 5, and the watering and draining The blower 5 can also blow off the water droplets on the surface of the parts while watering the parts. The top of the main body 1 of the pouring structure is provided with a fixed power chamber 6, and the fixed power chamber 6 is connected to the external power supply through the power line. For electrical ...

Embodiment 2

[0034] Such as Figure 1-5 As shown, on the basis of Example 1, the present invention provides a technical solution: the inner wall of the water drainage structure main body 1 is provided with a water quality clean plate 13, and the surface of the water quality clean plate 13 is fixedly installed on the surface of the water drainage structure main body 1. On the inner wall, a water quality treatment plate 14 is provided on the inner wall of the water drainage structure main body 1 and below the water quality cleaning plate 13. The combination of the water quality cleaning plate 13 and the water quality treatment plate 14 can carry out water flow through the water source poured in through the fixed drain pipe 2. Cleanliness treatment to ensure the sanitation and cleanness of the water quality. The surface of the water quality treatment plate 14 is fixedly installed on the inner wall of the main body 1 of the water drainage structure. Through the groove 18, the inner side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com