Secondary ink box for ink-jet printer

An inkjet printer, secondary ink cartridge technology, applied in printing and other directions, can solve the problems that affect printing quality, seals are easy to cause ink leakage, ink overflow, etc., to ensure the strength and installation reliability, avoid lack of ink or overflow. Ink, the effect of slowing down undulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

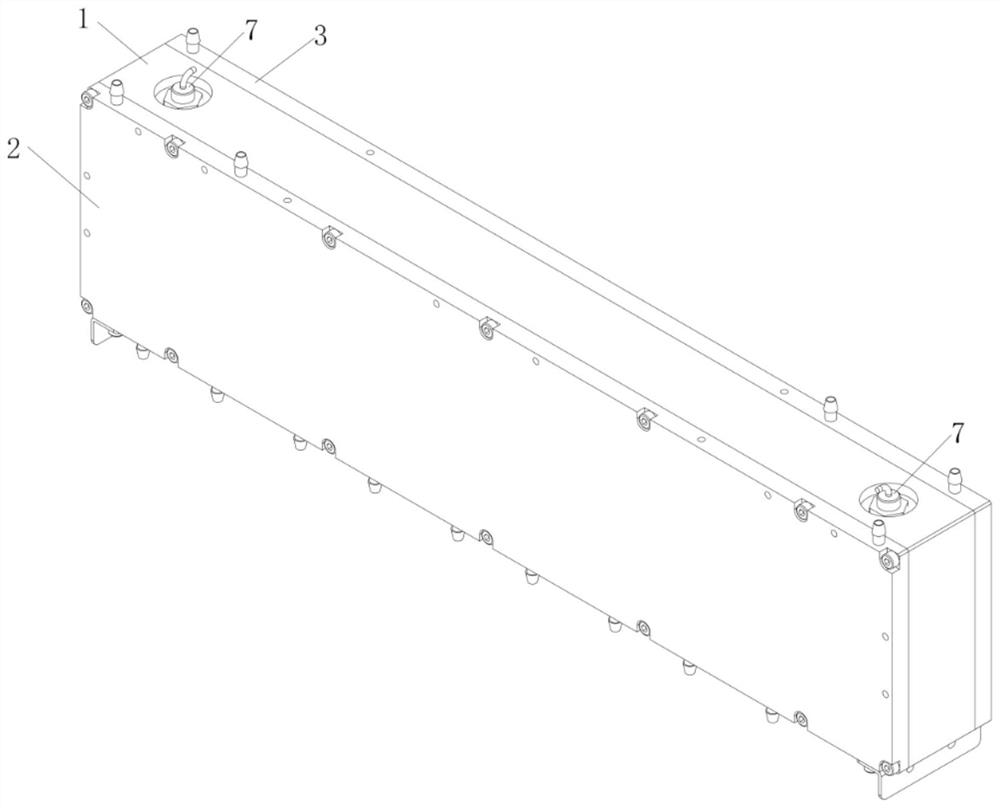

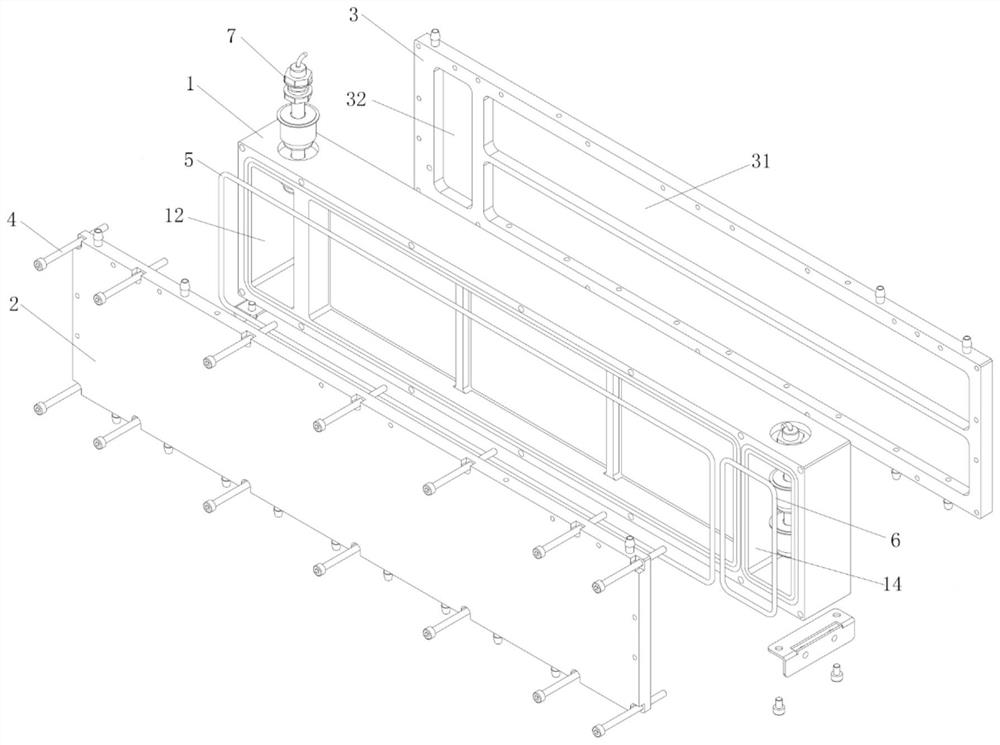

[0048] A secondary ink cartridge for an inkjet printer, comprising an ink cartridge body 1. The improvement is that the ink cartridge body 1 includes two ink tanks on both sides, and the outer sides of the two ink tanks are respectively covered with front ink tanks. Cover 2 and rear ink cover 3, the two ink tanks are closed with the front ink cover 2 and the rear ink cover 3 to form two mutually independent ink chambers, and the ink cartridge body 1 is equipped with two Liquid level sensor 7 for the amount of ink in the ink tank.

[0049] The two mutually independent ink chambers in the secondary ink cartridge in this embodiment can accommodate at least one kind of ink. It should be noted that the types of ink here include but are not limited to inks with different textures or inks with different colors. When it is necessary to print two-color or color patterns, the number of secondary ink cartridges required to be installed is halved, which not only helps to save the space oc...

Embodiment 2

[0060] On the basis of Example 1, the ink inlet connector, air source connector and ink outlet connector on the front ink cover 2 are integrally formed with the front ink cover 2, and the ink inlet connector, air outlet connector on the rear ink cover 3 The source connector and the ink outlet connector are integrally formed with the rear ink cover 3 .

[0061] The integrated molding structure in this embodiment avoids the ink leakage caused by the external connection method in the prior art, so that the service life of the secondary ink cartridge is longer.

Embodiment 3

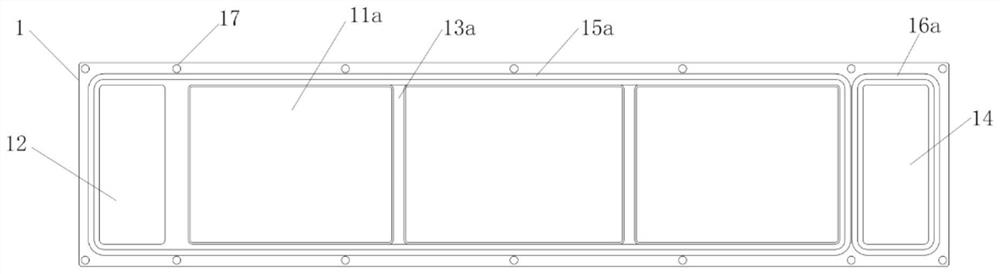

[0063] On the basis of Examples 1 and 2, with reference to Figure 1 to Figure 5 As shown, the two ink tanks are the first ink tank a 11a and the first ink tank b 11b located on both sides of the ink cartridge body 1, the front ink cover 2 and the rear ink cover 3 are respectively connected to the The first ink tank a11a and the first ink tank b 11b are closed to form two independent ink chambers.

[0064] Further, the cavities at the two ends of the ink cartridge body 1 are respectively the second ink tank 12 and the third ink tank 14, and the liquid level sensor 7 is installed in the second ink tank 12 and the third ink tank. In the tank 14; after the front ink cover 2 and the rear ink cover 3 are covered with the ink cartridge body 1, the second ink tank 12 communicates with the first ink tank a 11a and forms an independent ink tank cavity, the third ink tank 14 communicates with the first ink tank b11b and forms an independent ink cavity.

[0065] In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com