Substrate glass and manufacturing method

A manufacturing method and glass technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as low overflow quality, uneven plate thickness, and increased difficulty in plate thickness control, so as to improve product quality and ensure Overflow quality, the effect of ensuring the uniformity of overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

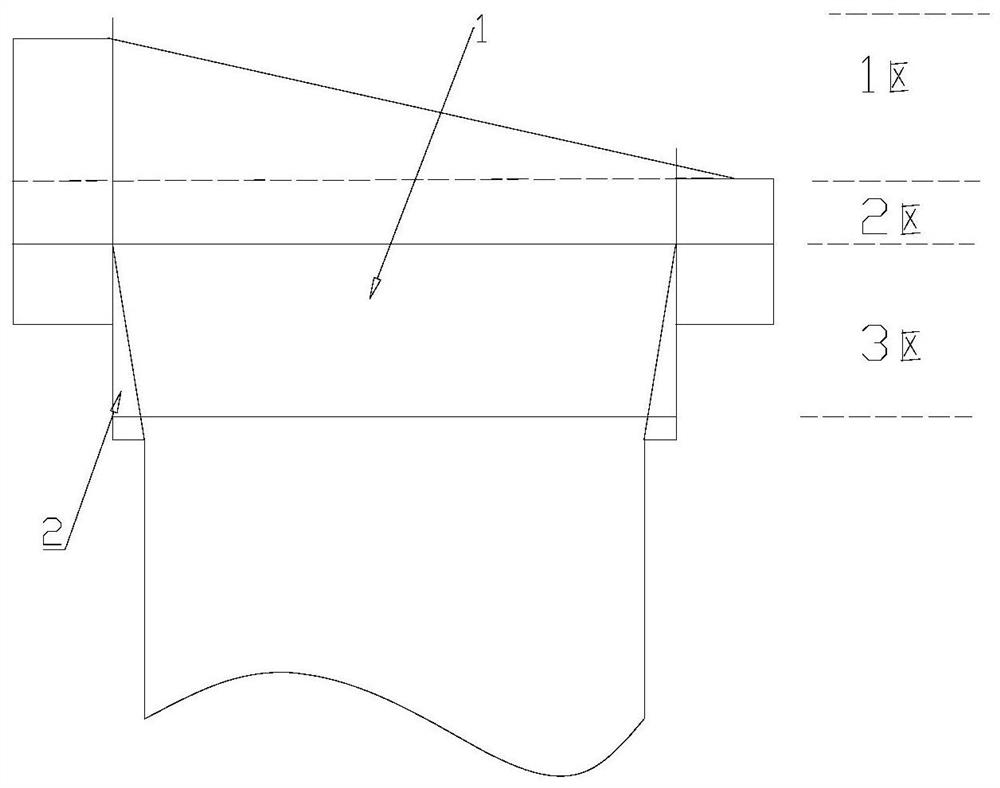

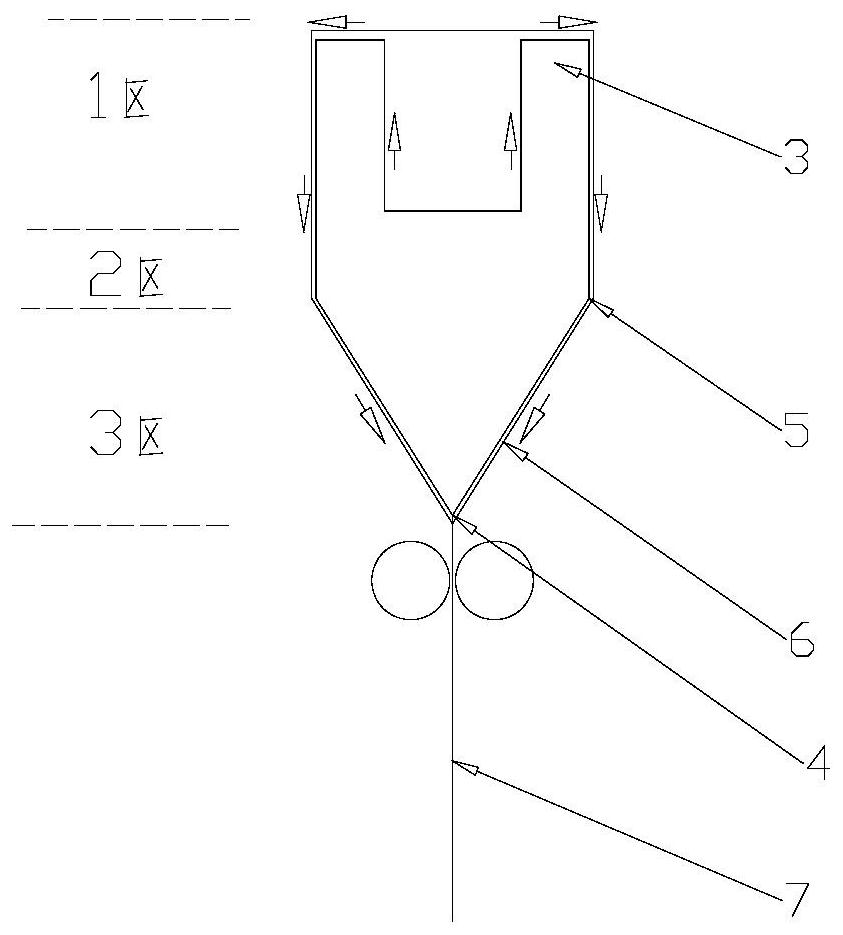

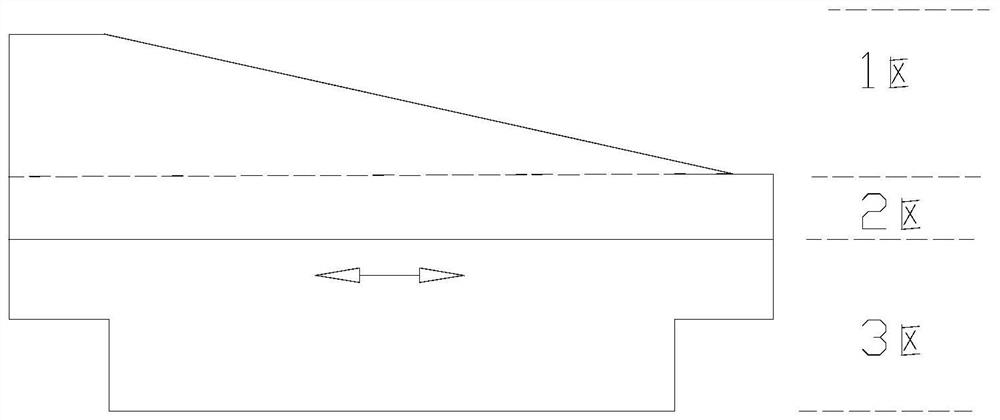

[0040] Such as Figure 1 to Figure 3 As shown, in the manufacturing method of the medium substrate glass of the present invention, the overflow tank 1 is divided into three regions along the height direction:

[0041] Zone 1: The upper starting point in the height direction is the highest point of the overflow weir 3, and the lower dead point is the lowest point of the overflow weir 3;

[0042] Zone 2: The upper starting point in the height direction is the lowest point of the overflow weir 3, and the lower dead point is the overflow edge 5 of the overflow tank 1;

[0043] Zone 3: The upper starting point in the height direction is the overflow side 5 of the overflow tank 1, and the bottom dead point is the bottom 4 of the overflow tank.

[0044]According to the characteristics of the overflow down-draw method, the entire plate is directly below the overflowing molten glass and is connected with the molten glass. When the lower solid glass plate 7 is integrally cut, the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com