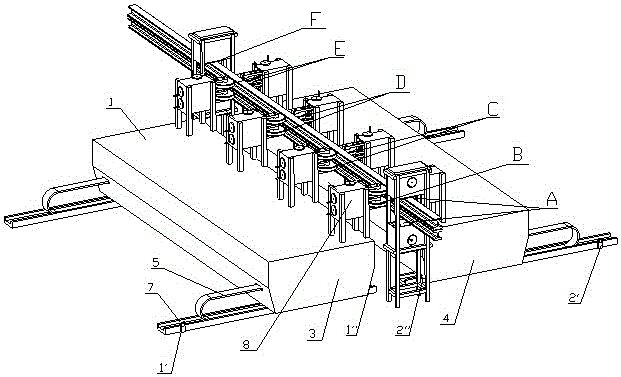

Third-rail online shaping device and its double-cylinder production method in conjunction with the third guide rail

A technology of shaping device and production method, which is applied in the field of aluminum alloy product control equipment, can solve problems such as deformation, and achieve the effects of eliminating waste, excellent repairability, and reducing cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Example 1 Random sampling Unit is (mm)

[0044]

example 2

[0045] Example 2 random sampling unit is (mm)

[0046]

[0047] It can be seen that after installation, the pass rate of the product is 98.9%, which far exceeds the pass rate of 30% when it is not installed, and the bending degree, twisting degree, and plane clearance of the material are all higher than the high-precision requirements of the national standard GB / T14846-2008 The 12mm, 5.9mm, and 0.552mm are much higher.

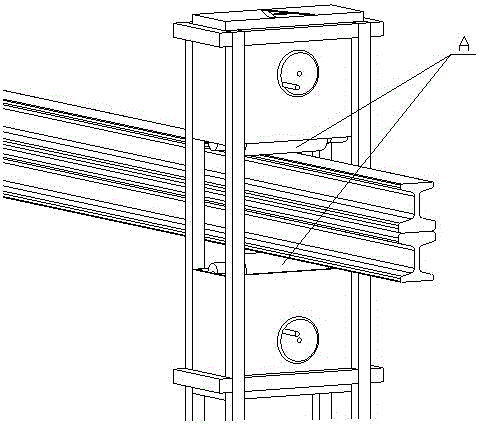

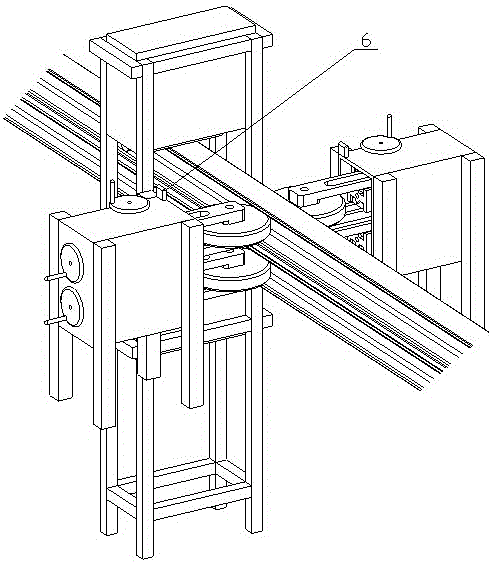

[0048] Figure 4a The shown double-bar extrusion equipment includes a clamp 11, a pressure plate 12, a guide 13, an extrusion cylinder 14, a central oil cylinder 15 and a main oil cylinder 16 fixed on the basis of the extrusion machine. A central oil cylinder 15 is provided in the main oil cylinder 16, and a transmission channel 17 of a wear-resistant conductive plate is provided in the middle of the main oil cylinder 16 and the central oil cylinder 15, and a transmission channel of a trolley line composite conductive track is opened on the clamp 11, betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com