A kind of preparation method of desorbent and performance evaluation method thereof

An evaluation method and technology of desorbents, which are applied in chemical instruments and methods, drilling compositions, instruments, etc., can solve the problem of high shale oil, shale oil can not use conventional oil and gas production system and evaluation method, shale oil The problem of low oil availability, etc., can reduce adsorption, improve emulsifying and solubilizing capacity, and reduce pharmaceutical costs and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a kind of preparation method of desorbent, and described preparation method comprises:

[0050] Add 20g of nonionic surfactant, 18g of cationic surfactant and 18g of dispersant into the container and stir until uniform to obtain the first reactant;

[0051] Add 15g of white oil to the first reactant and stir until it becomes a milky white emulsion to obtain the second reactant;

[0052] Add 4g of water to the second reactant and stir until the emulsion becomes clear and transparent to obtain a desorbent concentrate;

[0053] Dilute the desorbent concentrate with 2.5wt% potassium chloride aqueous solution, and dilute the desorbent concentrate to 0.1wt% to obtain a desorbent.

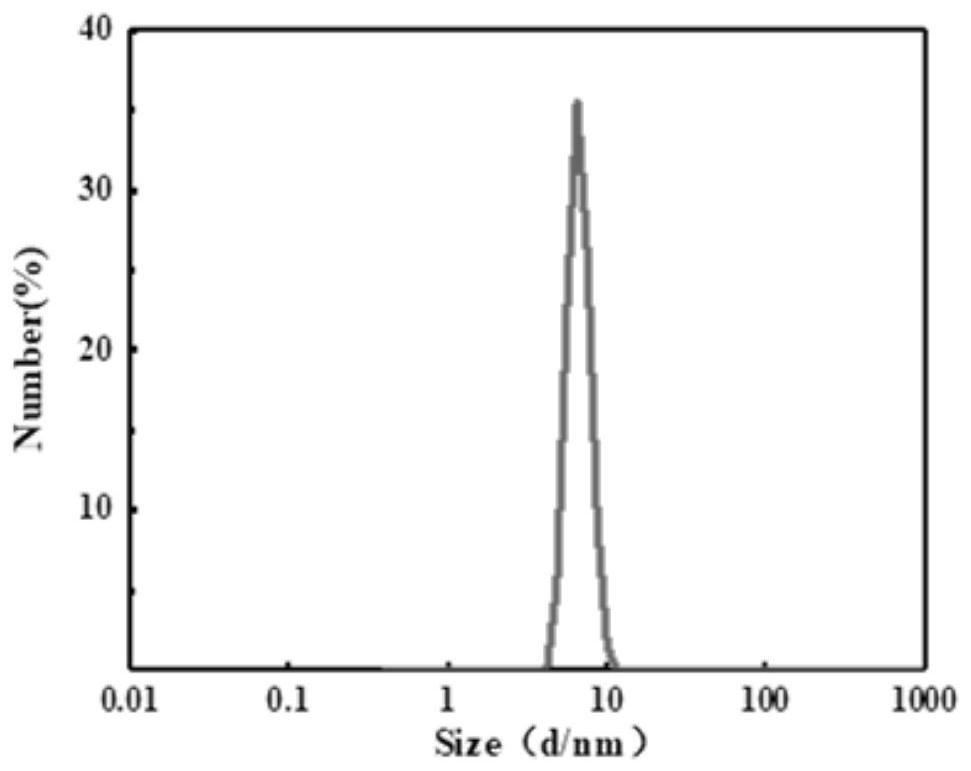

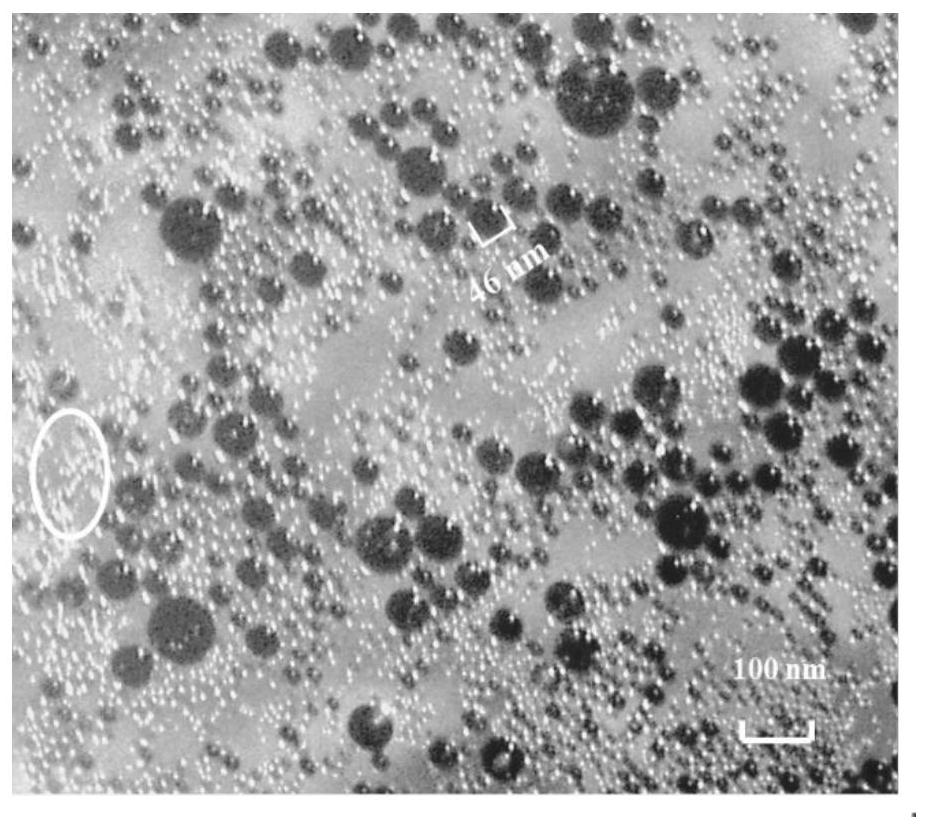

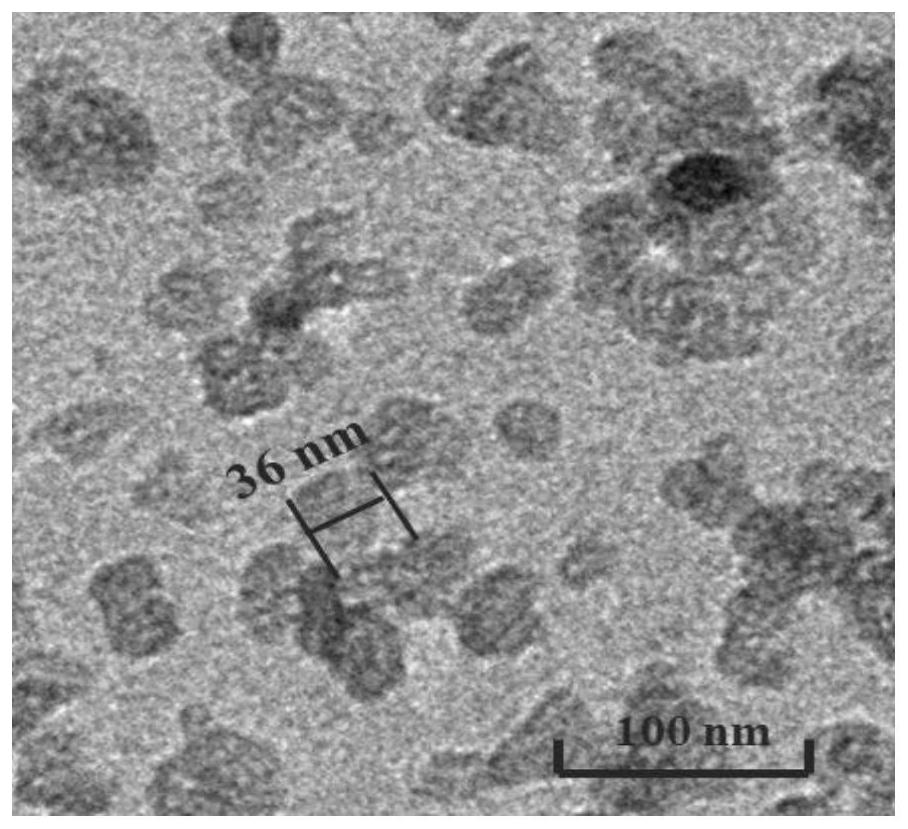

[0054] The appearance of the desorbent prepared in this example is clear and transparent, the particle size is 6-15nm, the interfacial tension is 1-2mN / m, and the wetting angle is 30°-60°.

Embodiment 2

[0056] The present embodiment provides a kind of preparation method of desorbent, and described preparation method comprises:

[0057] Add 35g of nonionic surfactant, 25g of cationic surfactant and 25g of dispersant into the container and stir until uniform to obtain the first reactant;

[0058] Add 25g of white oil to the first reactant and stir until it becomes a milky white emulsion to obtain the second reactant;

[0059] Add 10 g of water to the second reactant and stir until the emulsion becomes clear and transparent to obtain a desorbent concentrate;

[0060] Dilute the desorbent concentrate with 2.5wt% potassium chloride aqueous solution, and dilute the desorbent concentrate to 0.1wt% to obtain a desorbent.

[0061] The appearance of the desorbent prepared in this example is clear and transparent, the particle size is 6-15nm, the interfacial tension is 1-2mN / m, and the wetting angle is 30°-60°.

Embodiment 3

[0063] The present embodiment provides a kind of preparation method of desorbent, and described preparation method comprises:

[0064] Add 30g of nonionic surfactant, 20g of cationic surfactant and 21g of dispersing agent into the container and stir until uniform to obtain the first reactant;

[0065] Add 18g of white oil to the first reactant and stir until it becomes a milky white emulsion to obtain the second reactant;

[0066] Add 8g of water to the second reactant and stir until the emulsion becomes clear and transparent to obtain a desorbent concentrate;

[0067] Dilute the desorbent concentrate with 2.5wt% potassium chloride aqueous solution, and dilute the desorbent concentrate to 0.1wt% to obtain a desorbent.

[0068] The appearance of the desorbent prepared in this example is clear and transparent, the particle size is 6-15nm, the interfacial tension is 1-2mN / m, and the wetting angle is 30°-60°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com