Phi 40mm HRB600 high-strength aseismic steel bar and production method thereof

An anti-seismic steel bar and high-strength technology, applied in the direction of roll speed control, temperature control, metal rolling, etc., can solve the problems of difficult control of 40mm steel bar performance, poor performance stability, poor seismic performance, etc., to achieve improved plasticity and toughness, and small performance fluctuations , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

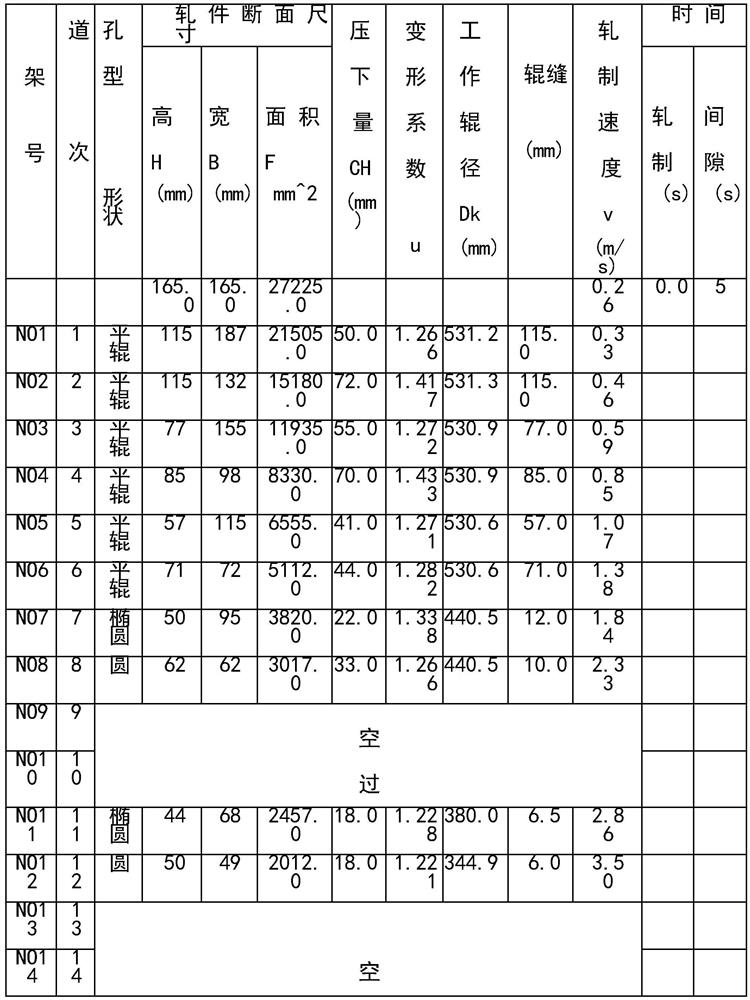

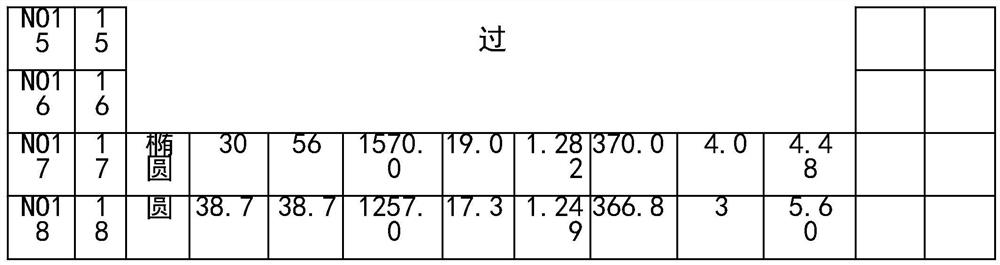

Image

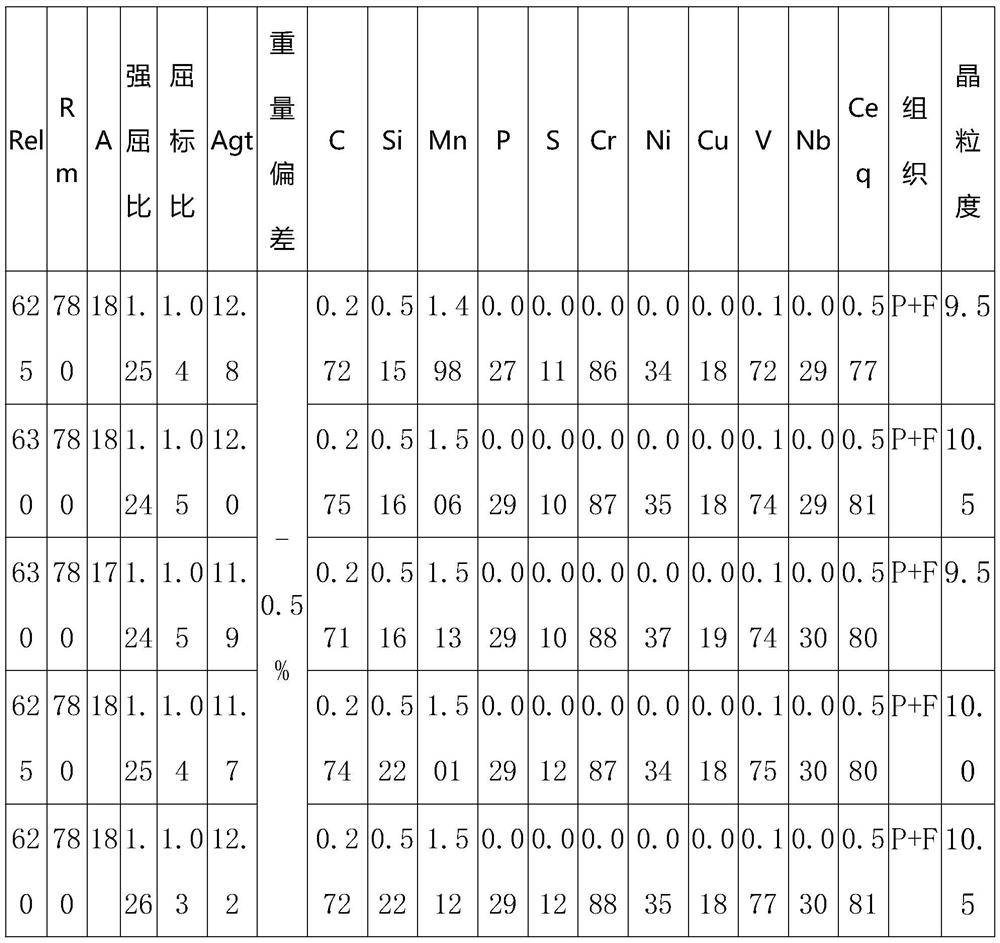

Examples

Embodiment Construction

[0017] A Φ40mmHRB600 high-strength anti-seismic steel bar, the chemical composition of which is by weight: C 0.25-0.27wt%, Si 0.50-0.65wt%, Mn 1.45-1.55wt%, S≤0.035wt%, P≤0.035wt%, V0.125~0.140wt%, Nb 0.025~0.030wt%, the rest is Fe and unavoidable impurities, Cr+Ni in impurities is the residual elements in molten iron and scrap steel, which can improve the corrosion resistance of steel bars.

[0018] A production process method of Φ40mmHRB600 high-strength anti-seismic steel bar, which comprises the following process steps:

[0019] Step 1: Put molten iron and steel scrap at 70±2t and 16±2t respectively into an 80-ton electric arc furnace for blowing with oxygen supply, and control the oxygen pressure at 0.75-1.05MPa, and then add CaO content ≥84% into the furnace in batches Slagging is carried out with high-quality lime, and the carbon content at the end point is controlled to be 0.08-0.12wt%, P≦0.025%, and the trace elements do not exceed the standard, and the temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com