Method for treating bridgehead bumping through transverse guide hole expansion jacking

A bridge head jumping and hole expansion technology, which is applied to roads, roads, buildings, etc., can solve problems such as abutment stability hazards, road surface subsidence, and uneven longitudinal settlement of road-bridge joints, achieving precise lifting and reset, durable and compressible , the effect of lower compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

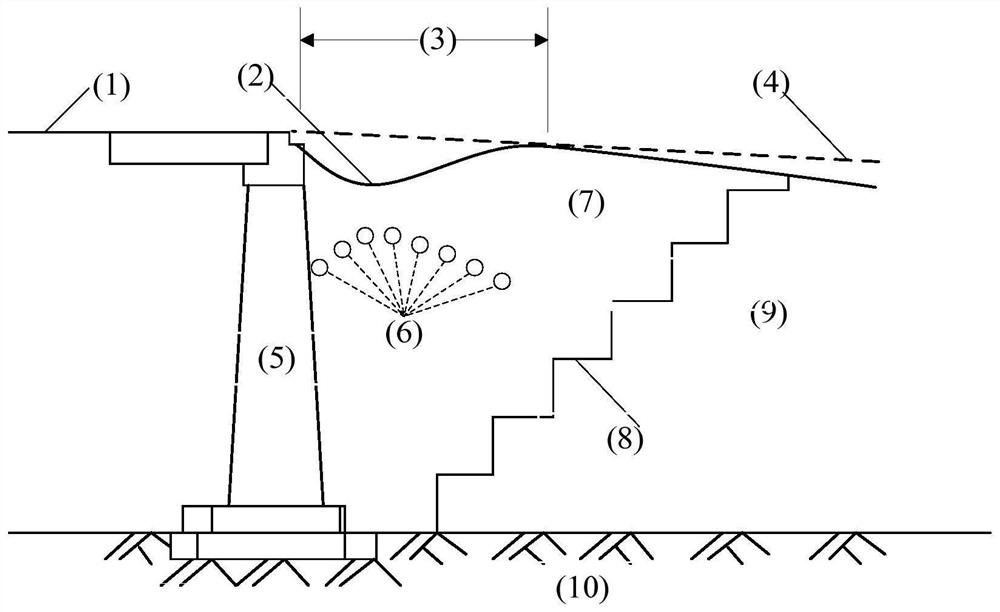

[0081] Example 1——Repair of differential settlement after bridge head lamination

[0082] There is a 10m-long bridge head slab in the transitional section of a high-grade highway. There is a maximum differential settlement of 10cm between the end of the bridge head slab and the junction of the subgrade, and "bridge head jumping" mainly occurs at the end of the bridge slab. In this regard, excavate and level the site to form an operation platform at the foot of the subgrade side slope within 5m from the end of the slab to the direction of the slab at the bridge head.

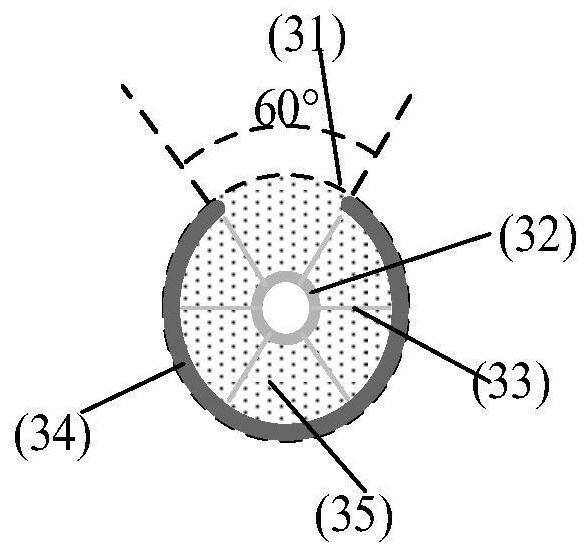

[0083] Since the differential settlement is relatively small, only a single layer of boreholes needs to be laid. Use a threaded drilling rig with a hole diameter of 60mm for construction; (below the top surface of the subgrade) the maximum hole depth is 1.50m, and the horizontal distance between adjacent holes is 100mm. In the longitudinal direction, the depth distribution curve of the drilled holes matches the ...

Embodiment 2

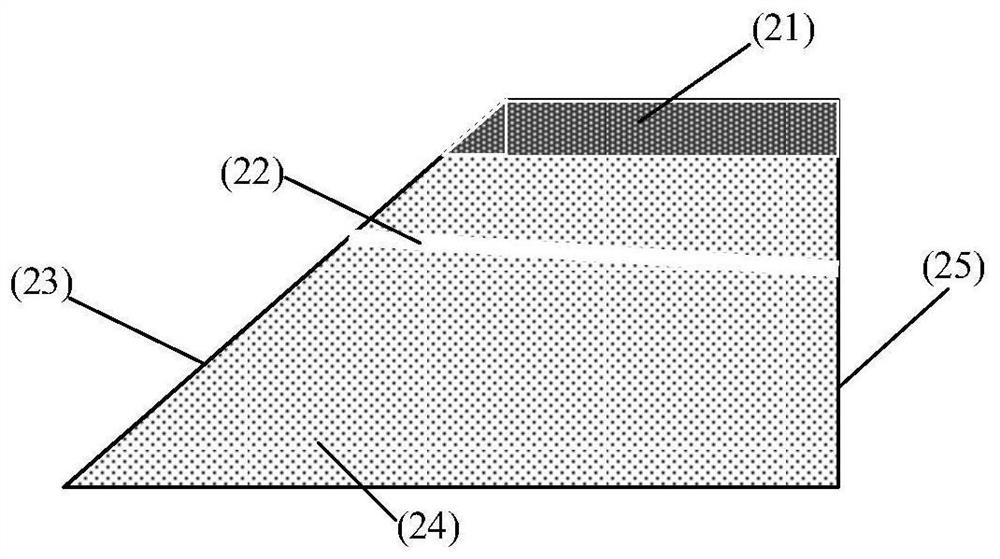

[0091] Example 2——repair of hollowing out disease of bridge head lap slab

[0092] There is a 6m-long bridgehead slab in the transitional section of a secondary highway. There is a gap of up to 24cm under the bridgehead slab, and the slab is seriously damaged under the action of heavy vehicles. In this regard, excavate and level the site to form an operation platform at the foot of the subgrade slope within 6m of the slab at the bridgehead section.

[0093] Due to the relatively large differential settlement, it is necessary to lay out two layers of boreholes, and the distance between the upper and lower layers of drill holes is 30cm. Use a threaded drilling rig with a hole diameter of 100mm for construction; (below the top surface of the subgrade) the maximum hole depth is 1.20m, and the horizontal distance between adjacent holes is 60mm. In the longitudinal direction, the depth distribution curve of the drilled holes matches the surface deformation curve of the void.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com