A preloading construction method of assembled 0# block construction bracket

A construction method and prefabricated technology, which is applied in erecting/assembling bridges, buildings, bridge construction, etc., can solve problems such as torsion and deformation of brackets, vulnerability to environmental influences and climate, and increase in safety risks, so as to avoid torsion and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

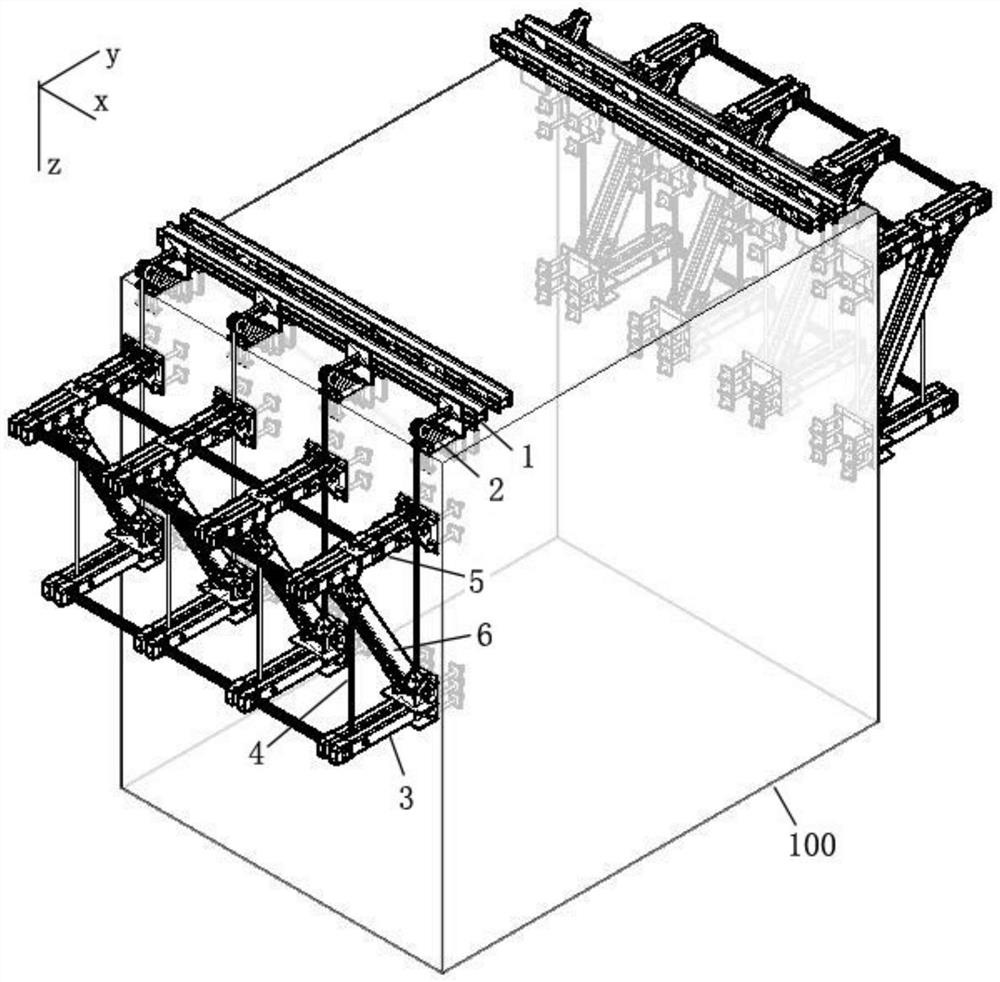

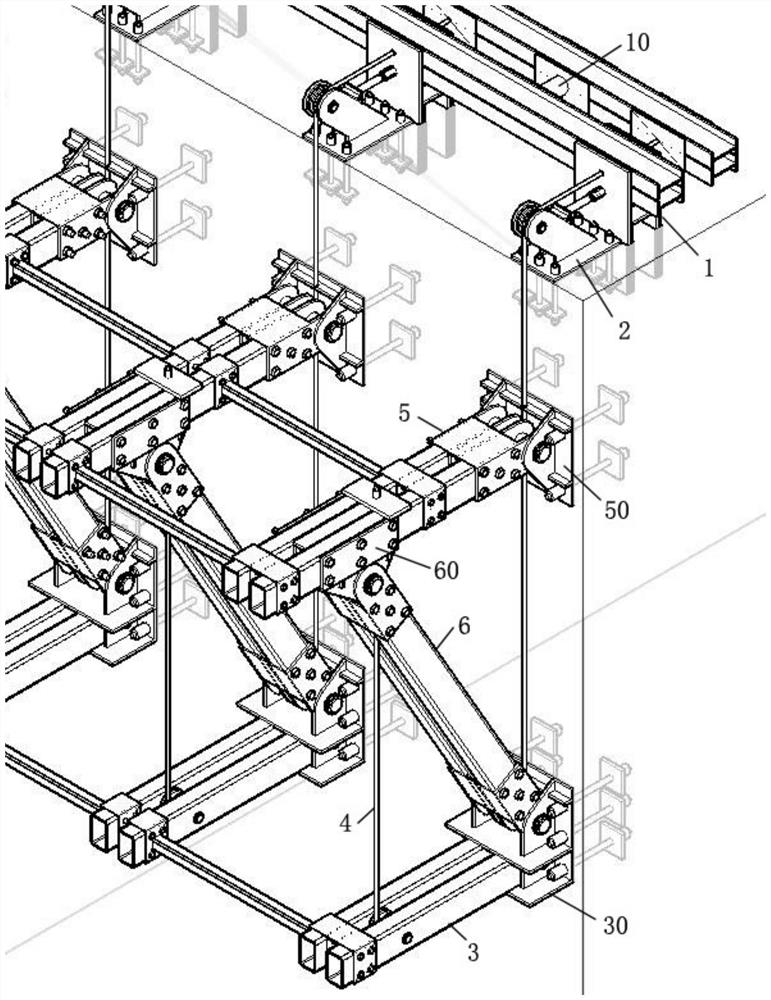

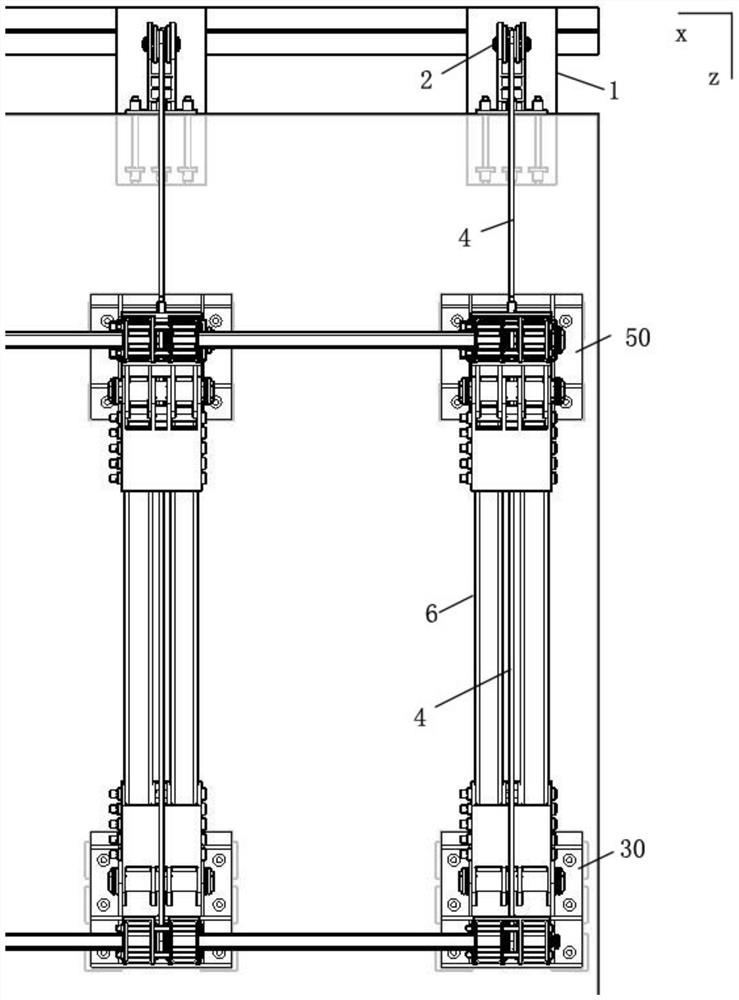

[0071] The specific implementation of the invention is further described below in conjunction with the accompanying drawings.

[0073] Referring to FIG. 4, the 0# block construction bracket of the present invention is based on the tension loading of the preloaded load member, and the direction is changed through the pulley block,

[0076] The pre-compression assembly includes a pre-compression load member 10 and a pre-compression spare part, and the pre-compression spare part includes a support assembly 1, a cable saddle assembly 2,

[0077] Referring to FIGS. 7-9, the cable saddle assembly 2 is arranged on the top wall of the bridge pier body 100 through the embedded assembly III 103.

[0084] Wherein, the support assembly 1 includes a card seat 11 and a card slot, including an outer card seat 111, a middle card seat 113, an inner card seat 112 and a lining

[0085] Referring to Figures 1-9, as an option, based on the foregoing example, in this example, the pre-compression assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com