Sleeve equipment for preventing short pile from being frozen and pulled out in frozen earth area and using method

A casing equipment and casing technology, applied in sheet pile walls, protection devices, buildings, etc., can solve problems such as increasing project cost, and achieve the effects of saving project cost, low friction coefficient, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

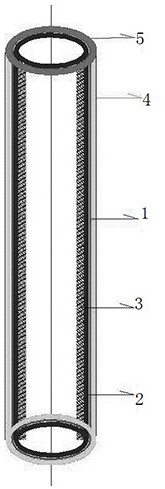

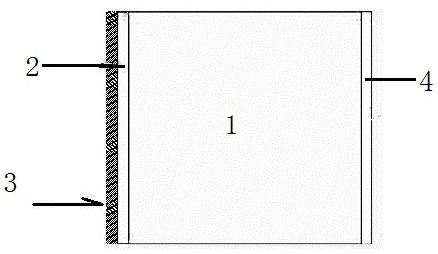

[0028] Such as figure 1 As shown, a kind of anti-short pile freeze-pull casing equipment in permafrost areas includes a casing 1 set outside the prefabricated pile, the inner wall of the casing 1 is coated with an adhesive layer 2, and the adhesive layer 2 is provided with a filling layer 3. The outer wall of the casing 1 is coated with a lubricating layer 4, and the inner wall of the upper end of the casing 1 is also connected with a sealing rubber ring 5.

[0029] The casing 1 is a PE pipe.

[0030] The adhesive layer 2 is adhesive glue sprayed on the inner wall.

[0031] The filling layer 3 is wood chips.

[0032] The lubricating layer 4 is a hydrophobic lubricating glue.

[0033] Such as figure 2 As shown, the casing 1 is hollow inside, and its inner diameter is about 5mm larger than the diameter of the prefabricated pile. The entire casing 1 is placed outside the prefabricated pile.

[0034] Spray the chipped wood chips on the adhesive layer 2, and the chipped wood ...

Embodiment 2

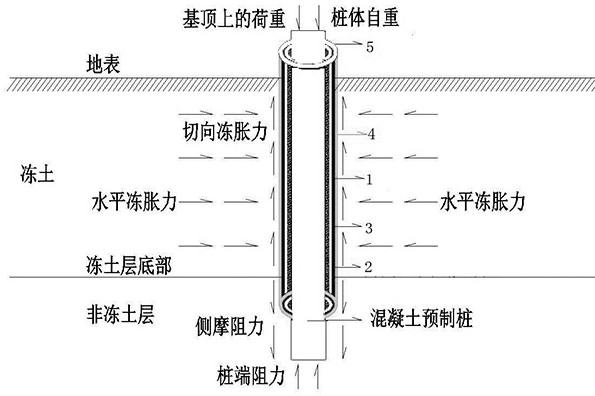

[0037] On the basis of Example 1, such as image 3 Shown, a kind of use method of anti-short pile freeze-pull casing equipment in permafrost region, comprises the following steps:

[0038] The casing is prefabricated, the adhesive glue is sprayed on the inner wall of the casing 1 to form an adhesive layer 2, and the hydrophobic lubricating glue is sprayed on the outer wall of the casing 1 to form a lubricating layer 4;

[0039] The filling layer is prefabricated, and the wood chips are sprayed on the inner wall of the casing 1, and the wood chips are stuck on the adhesive layer 2 to form the filling layer 3;

[0040] Place the prefabricated pile 6 and the casing 1 in the prepared hole, and insert the prefabricated pile 6 into the casing 1, and the upper end of the casing 1 is exposed to the surface,

[0041] Where the casing 1 and the pile body are exposed to the surface, a sealing rubber ring 5 is inserted into the gap between the inner wall of the casing 1 and the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com