Energy-saving prefabricated building wall and its construction technology

A technology for building walls and construction techniques, applied in buildings, building components, building materials, etc., can solve the problems of low connection firmness, achieve the effects of increasing building energy saving, reducing heat transfer, and increasing thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-6 The application is described in further detail.

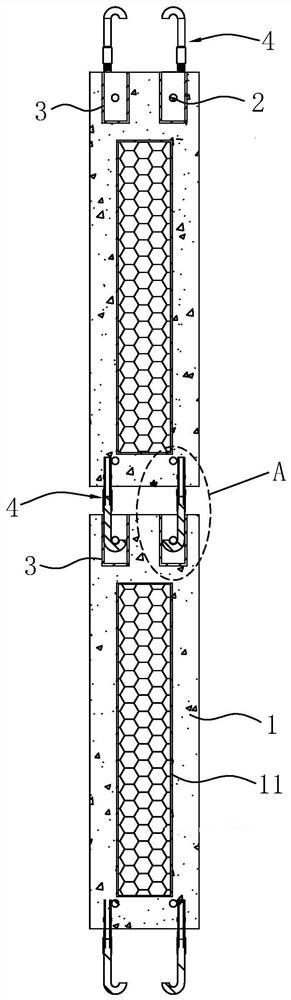

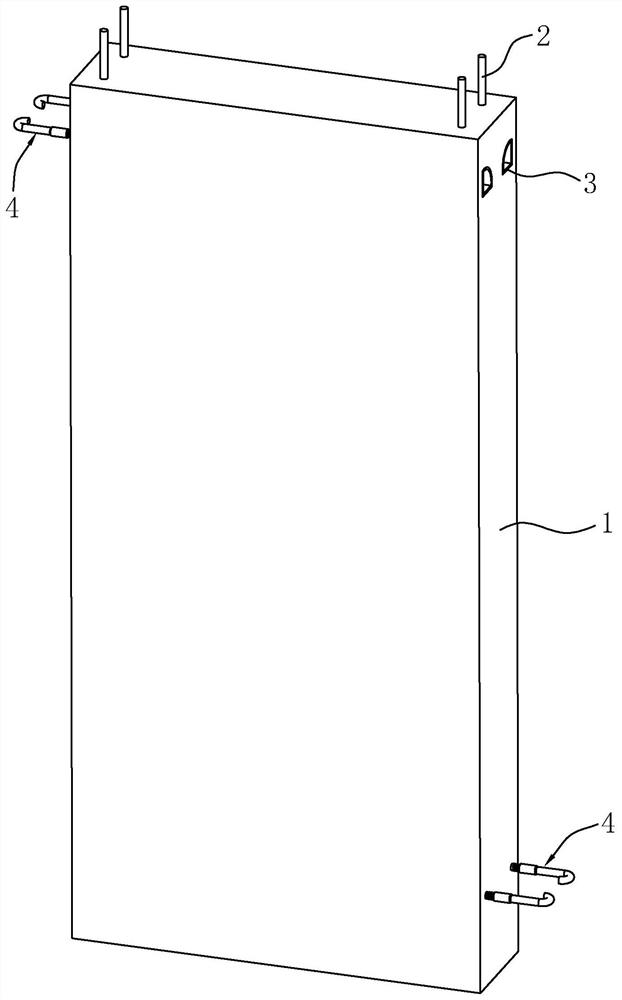

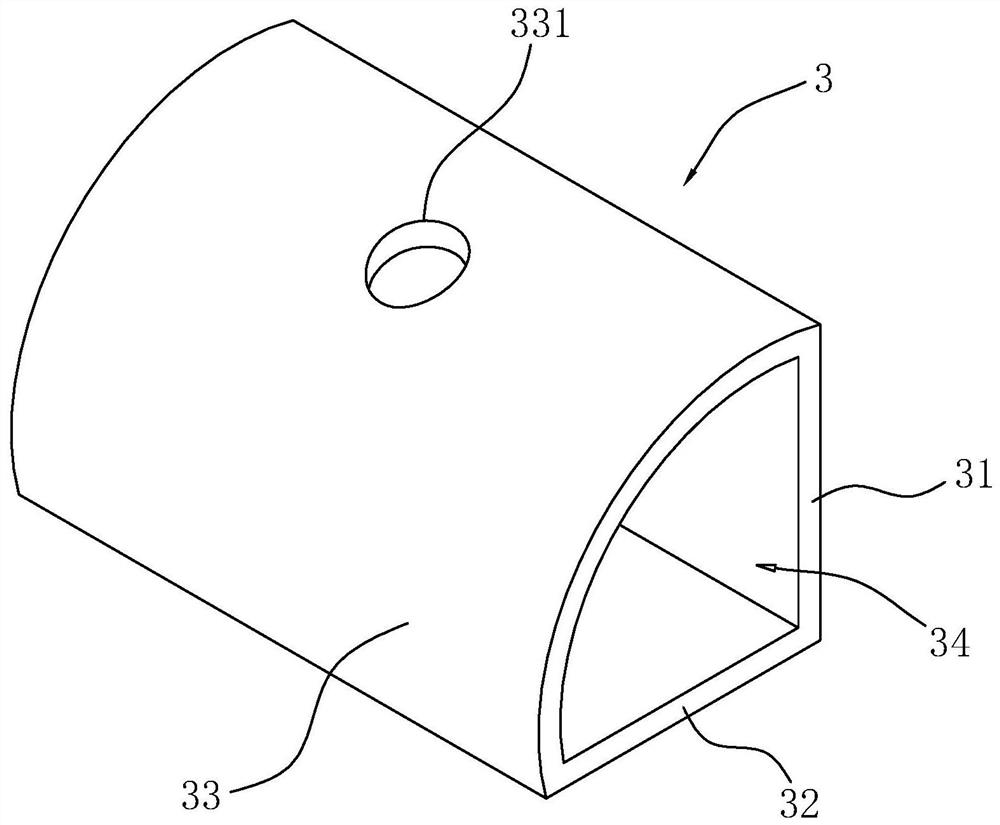

[0045] The embodiment of the present application discloses an energy-saving prefabricated building wall. refer to figure 1 and figure 2 , the energy-saving prefabricated building wall includes a board body 1 and an inner rib 2 installed on the board body 1, a pre-embedded shell 3 and a connecting component 4, the inner rib 2 is set through the pre-embedded shell 3, and the pre-embedded shell 3 and the connecting component 4 are arranged on opposite sides of the plate body 1 and their positions correspond to each other.

[0046] refer to figure 2 , The board body 1 can be a reinforced concrete board, and the board body 1 is embedded with an insulation board 11, and the insulation board 11 can be a polystyrene board or a rubber-plastic board, etc., which can increase the insulation performance of the board body 1. The reinforcement cage in the board body 1 is in a cuboid structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com