Hydrogen embrittlement detector for high-strength steel production

A detector, high-strength technology, applied in the field of hydrogen embrittlement of steel, can solve the problems of internal hydrogen molecule damage, steel fracture, difficult comparison, etc., to reduce time, reduce preparation work, and avoid visual fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

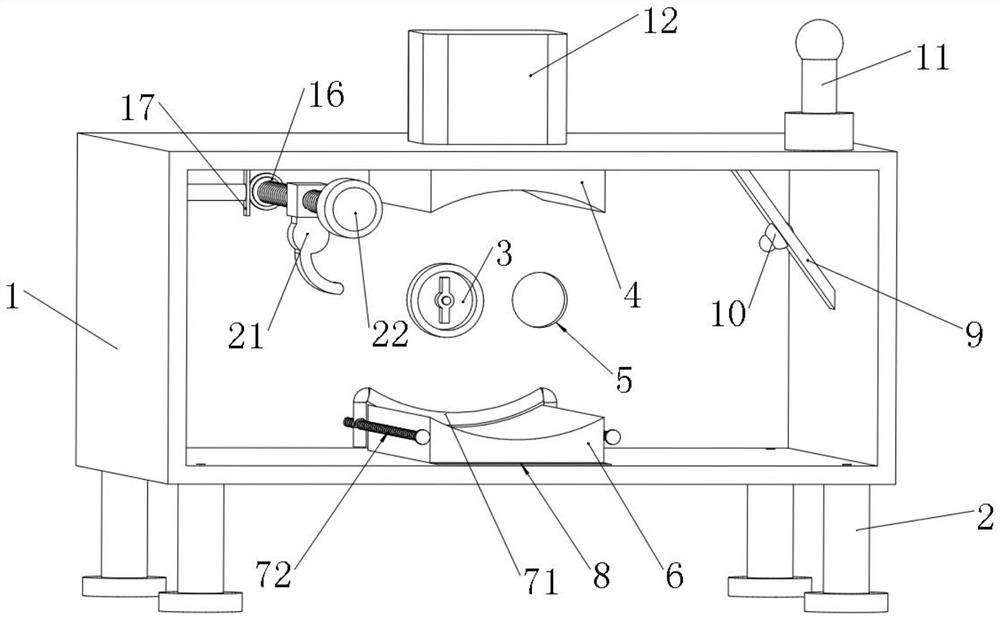

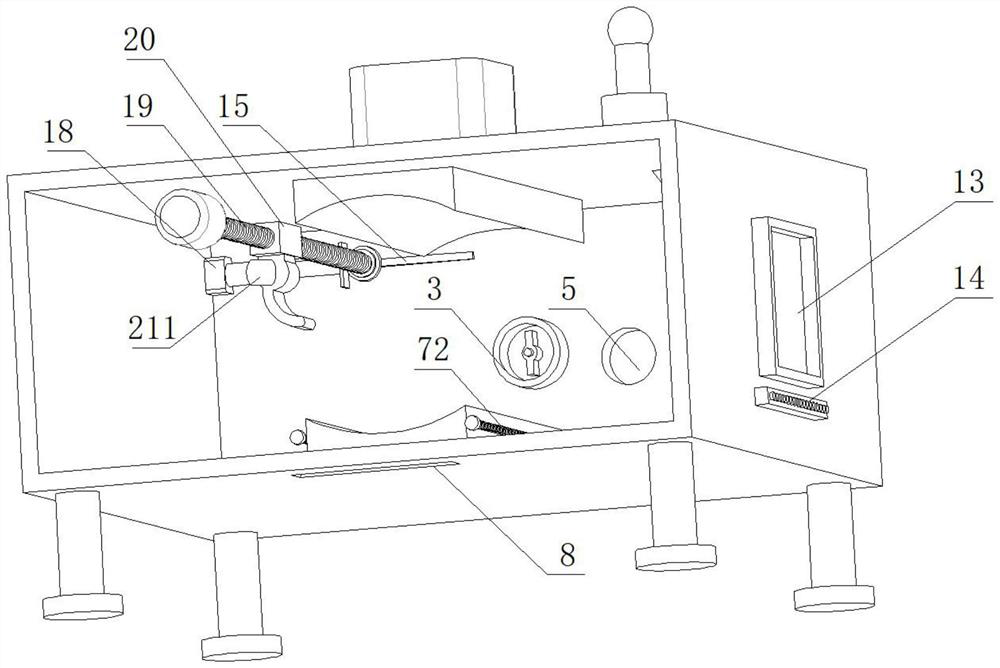

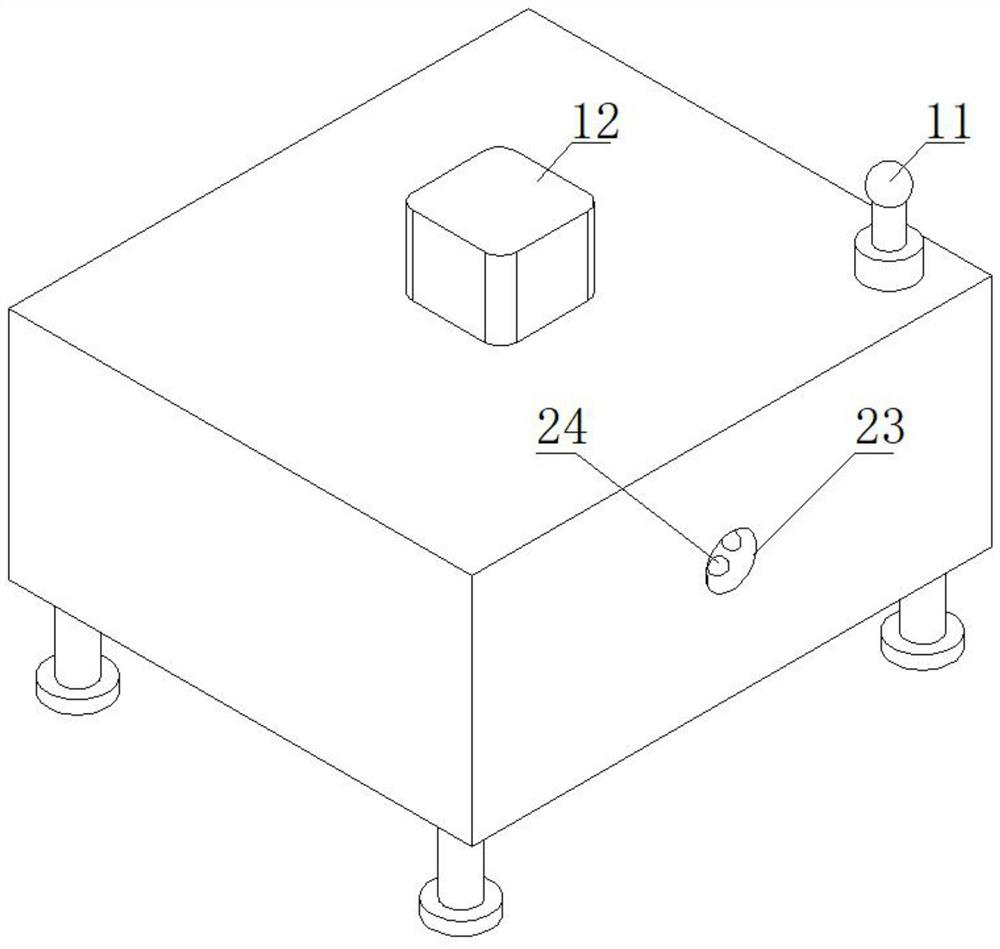

[0039] When installing, producing or assembling this device, it is necessary to set and open the steel reinforcement limiter 3 and the steel entry hole 23 on the same horizontal line, and the steel reinforcement limiter 3 and the steel entry hole 23 are symmetrically installed in the detection On the main body shell 1 of the device, one end and the other end of the steel are fixed on the steel reinforcement limiter 3 and the steel entry hole 23. At the same time, the recording camera 10 needs to be aimed at the steel. The recording camera 10 records need no dead angle, and The traversing motor 22 is fixed on the other surface inside the main body shell 1 of the detector through the traversing slide rail 15, and the steel-driven bump 33 is a bump made of an 'I' shape, and the steel-driven bump 33 is the inside of the end face. Nested with a vibration detection sensor 34, the steel needs to be raised before detection. An 'I'-shaped clamping groove is provided on the end face, and...

Embodiment 2

[0041] And the steel reinforcement limiter 3 includes a steel main body wrapping shell 31, a steel material entry groove 32, and the steel material drives a bump 33 and a vibration detection sensor 34, and a steel material entry groove 32 is provided in the steel material main body wrapping shell 31, and a steel material entry groove 32 is provided with a steel material entry groove 32. Drive the bump 33 and the vibration detection sensor 34, the steel main body wrapping shell 31 is connected with the drive shaft on the drive motor on the outer surface of the detector main body shell 1, and the debris processing assembly 7 includes a debris removal body 71, and a moving cleaning rod 72, Restricting block 73 and cleaning power motor 74, one end of two mobile cleaning rods 72 passes under the both sides of the debris removal body 71, the debris removal body 71 is a pushing body made in an 'M' shape, and the debris removal body 71 The inner shape is a concave arc, and one end of t...

Embodiment 3

[0043] A kind of steel hydrogen embrittlement test device that National Patent No. CN 212674599 U involves, the time required for detection is as follows: severe hydrogen embrittlement steel --- fracture time is several minutes to several hours, higher hydrogen embrittlement steel -- --Steel with a fracture time of several hours to tens of hours and low hydrogen embrittlement (qualified steel) ---The fracture time is tens of hours to hundreds of hours, and the time required for the detection of this device is as follows: serious Hydrogen embrittlement --- fracture time is a few minutes to 7 hours, higher hydrogen embrittlement --- fracture time is 7 hours to 25 hours, lower hydrogen embrittlement --- fracture time is 25 hours to 70 hours, from the above data It can be seen that the hydrogen embrittlement device only needs 70% of the time of the above-mentioned device to complete the detection of its steel, which is convenient to reduce the large amount of time required for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com