Laser cutting platform cleaning device

A cleaning device and laser cutting technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of ineffective cleaning of the blade and poor cleaning effect of the tooth tip, and achieve the promotion of cleaning, easy removal, and smooth operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

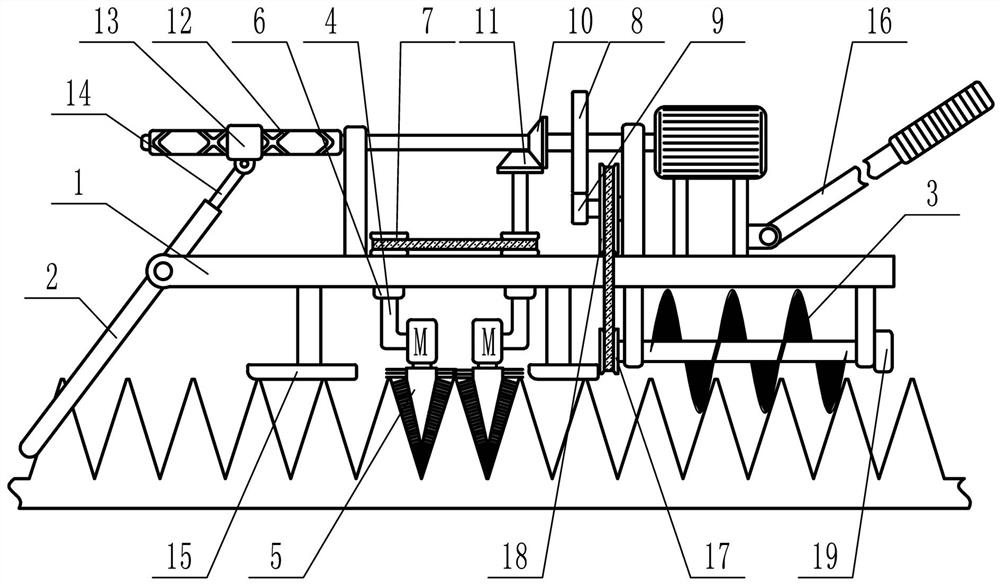

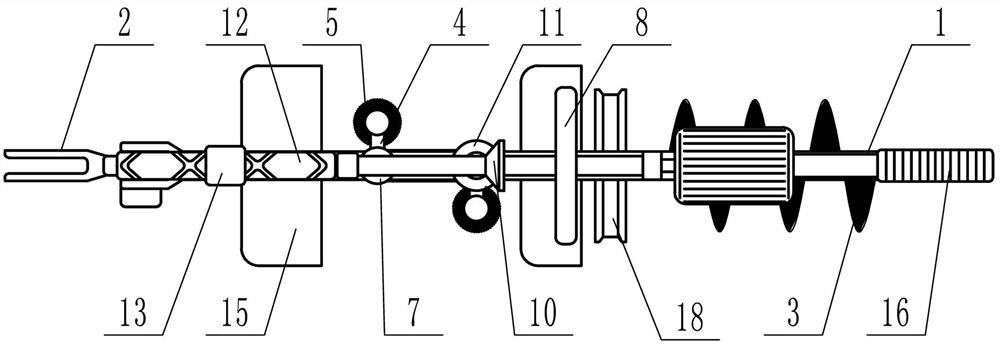

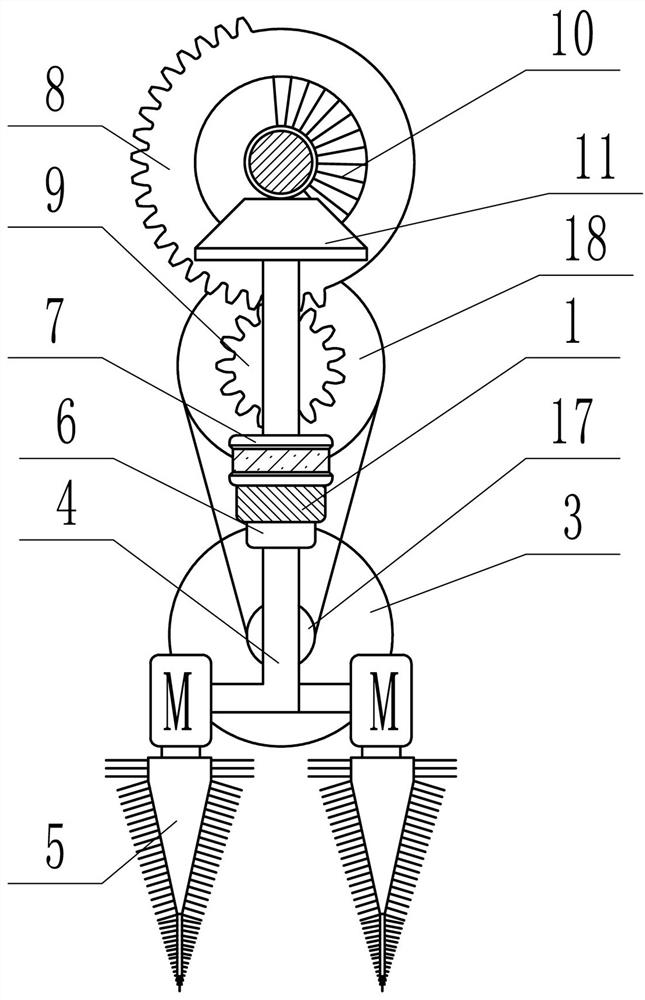

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Depend on Figure 1 to Figure 3 It can be seen that the present invention includes a horizontal bearing rod 1, the left end of the bearing rod 1 is provided with a U-shaped fork 2, the fork handle of the U-shaped fork 2 is hinged with the end of the support rod, and the fork of the U-shaped fork 2 is inserted into the sword grid. On the support bar, a helical blade 3 with a shaft is arranged below the right end of the bearing bar 1, and the helical blade 3 engages with the teeth on the support bar. The lower end of the shaped rod 4 is fixed with a vertical motor-driven cone 5, and each L-shaped rod 4 is provided with a coil spring 6 fixed on the bearing rod 1, and the outer edge surface of the cone 5 is sealed with steel wire bristles. , the upper end of each L-shaped bar 4 is fixed with a first pulley 7, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com