Clamp for machining cylindrical workpiece

A cylindrical and workpiece technology, which is applied in the field of fixtures used for processing cylindrical workpieces, to avoid high specific heat capacity, and to ease deformation and color changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

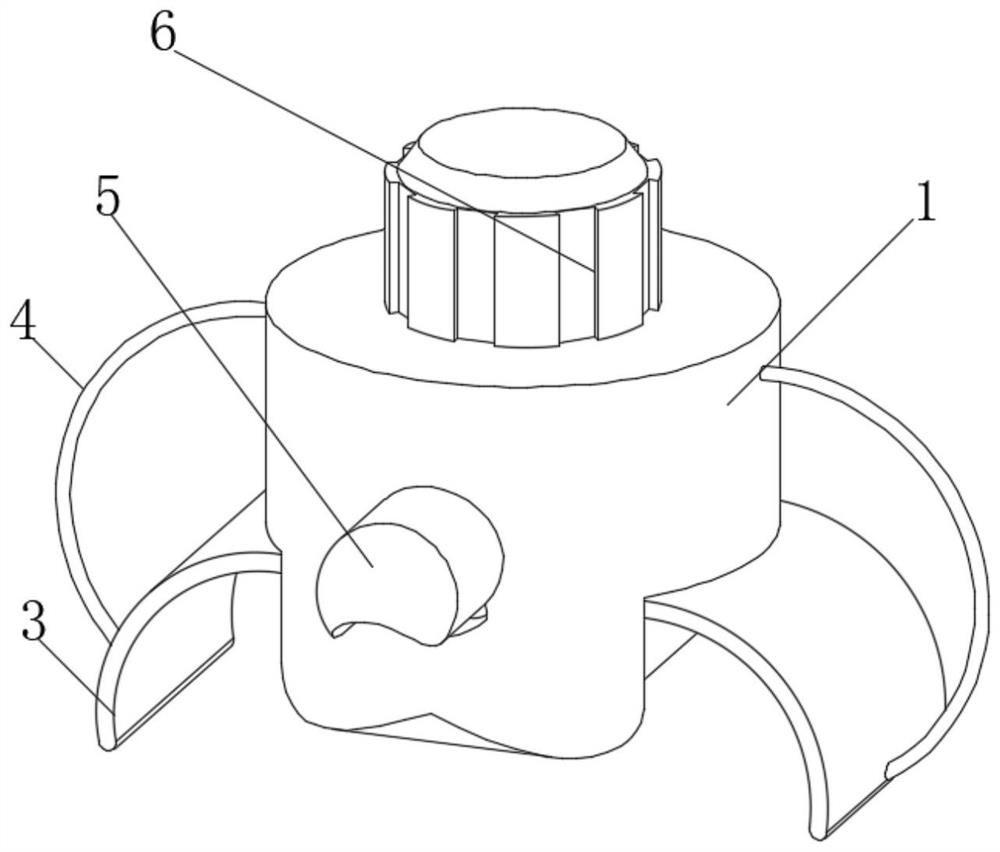

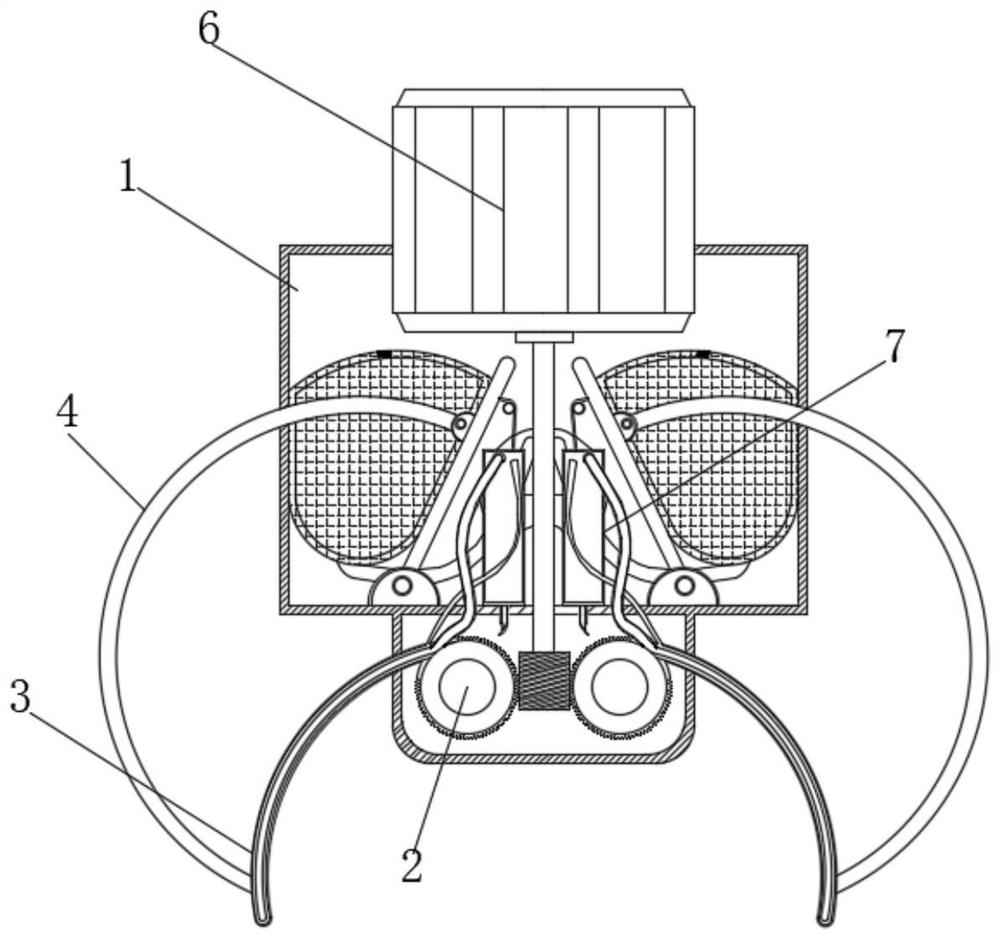

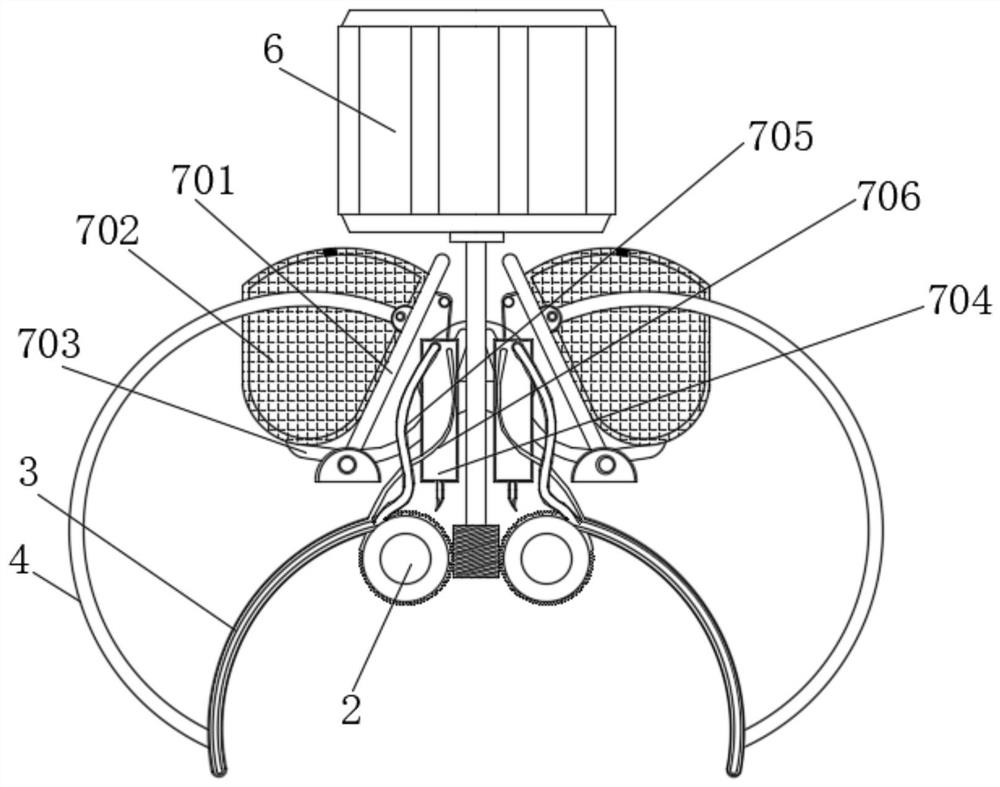

[0022] Such as Figure 1-6 As shown, the present invention provides a technical solution: a fixture for processing cylindrical workpieces, including a casing 1, the lower outer wall of the casing 1 is fixedly connected with a fixed pile 2, and the outer wall of the fixed pile 2 rotates through a bearing The splint head 3 is connected, the outer wall of the splint head 3 is fixedly connected with the pull rod 4, the upper surface of the casing 1 is embedded with a motor 6, the outer wall of the right end of the splint head 3 is provided with a toothed structure, and the lower end of the output rod of the motor 6 passes through the threaded rod and The right end of the splint head 3 is engaged and connected, the outer wall of the casing 1 is provided with a blower mechanism 5 , and the inside of the casing 1 is provided with a transmission mechanism 7 .

[0023] The transmission mechanism 7 includes a splint 701, an air bag 702, a first air supply pipe 703, a cooling mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com